HMCVT three-planet-row converging mechanism of high-power tractor

A planetary and tractor technology, applied in mechanical equipment, transmission devices, control devices, etc., can solve the problems of excessive vibration and the inability of the double-row planetary gear mechanism to meet low-speed and high-torque operations, and achieve a small number of parts and a simple structure. , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

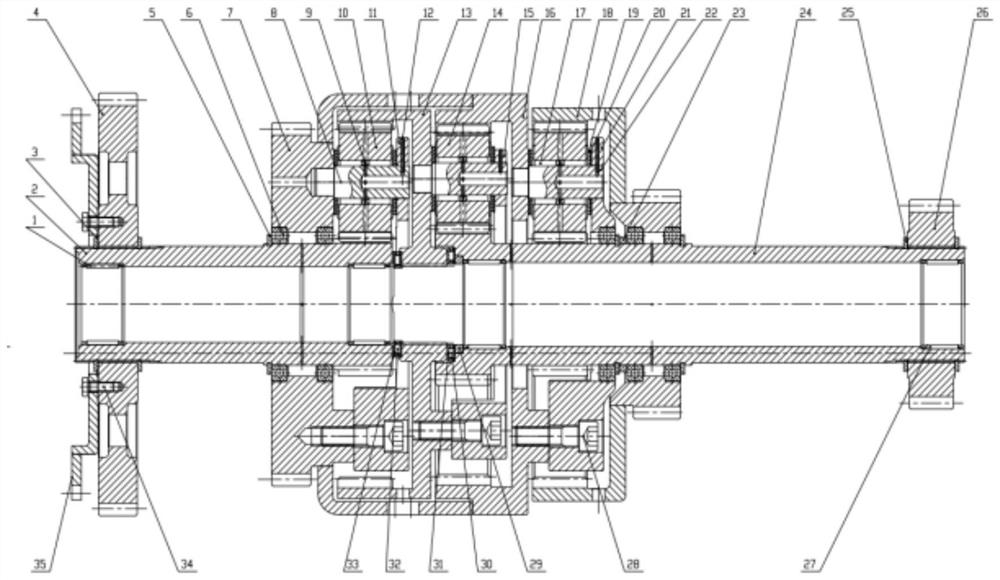

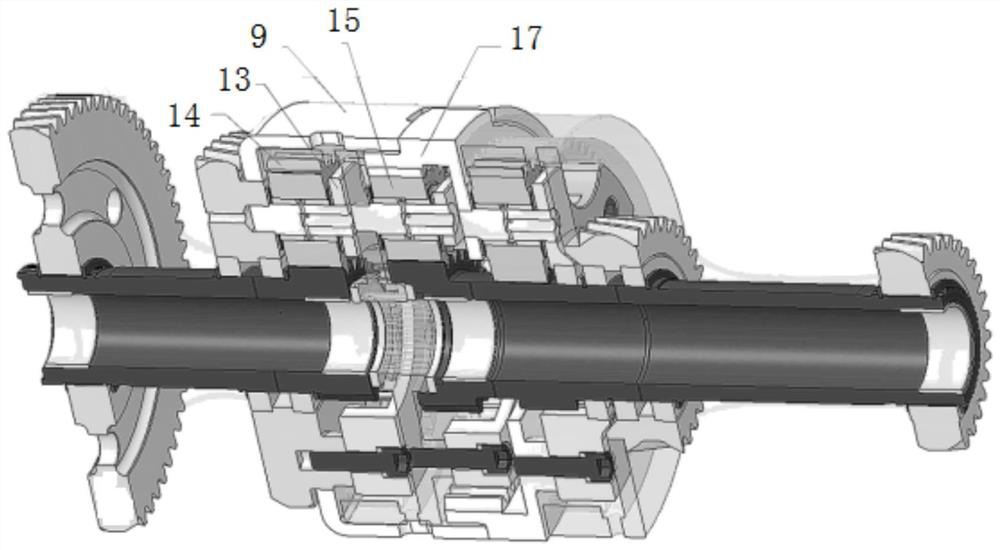

[0025] Such as Figure 1-3 As shown, the present invention is a high-power tractor HMCVT three-planet confluence mechanism, including a three-planet confluence mechanism, an interlocking connection to further optimize the planetary gear mechanism, and an interlocking connection to further optimize the planetary gear mechanism;

[0026] The confluence mechanism of three planetary rows includes needle roller bearing 1, P1 sun gear 2, shaft circlip 3, motor shaft driven wheel 4, shaft circlip 5, deep groove ball bearing 6, and C3 driving wheel sleeve welding 7. P1P2 planetary shaft 8, needle roller bearing spacer 9, P1P3 planetary wheel 10, P1 planetary carrier 11, elastic pin 12, P1 ring gear 13, P2 planetary wheel 14, P2 planetary carrier 15, P2 ring gear 16, needle roller Bearing 17, C1 driving wheel ring gear welding 18, thrust copper washer 19, thrust steel washer 20, P3 planet carrier 21, P3 planet wheel shaft 22, C1 bearing washer 23, triple gear 24, circlip for shaft 25....

Embodiment 2

[0030]Among them, the jaw-type coupling mechanism includes hydraulic power and mechanical power. The hydraulic power is obtained through the motor shaft driven gear 4 under the action of hydraulic force, and the P1 sun gear 2 is driven to rotate with it through the spline, and the P1P3 planetary shaft 10 meshes with the sun gear, the power is transmitted to the planetary gear of the P1 planetary row, the P1 planetary row receives power, and the power of the mechanical road is directly transmitted to the P1 ring gear 13 through the power input shaft for confluence in the planetary row. The converging power is output through C3 driving wheel sleeve welding 7, C1 driving wheel ring gear welding 18 and C2 driving wheel 26.

[0031] A specific application of this embodiment is: the C3 drive wheel sleeve is welded and the end surface of the P2 ring gear is processed with corresponding teeth, which can be fitted with each other. The two cooperate with each other and can play the role...

Embodiment 3

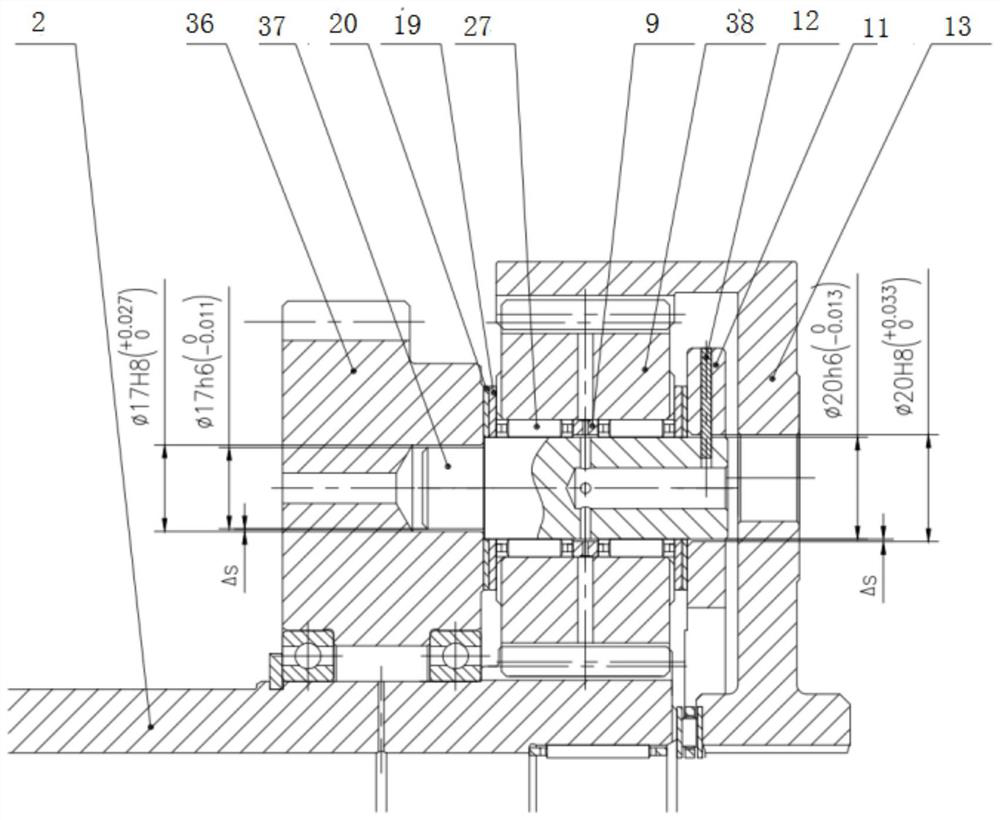

[0033] Among them, the floating mechanism consists of P1 sun gear 2, C3 driving wheel 36, P1 planetary wheel shaft 37, thrust steel gasket 20, thrust copper gasket 19, needle roller bearing 27, needle roller bearing spacer 9, P1 planetary wheel 38. The elastic pin 12, the P1 planetary carrier 11 and the P1 ring gear 13 form a set of planetary gear mechanism. The P1 planetary gear shaft 37 cooperates with the shaft hole on the C3 driving wheel 36 and the P1 planetary carrier 11 with clearance, and the axial direction is carried out through the elastic pin 12. Radial positioning, leaving a floating gap △s, a little displacement along the radial direction.

[0034] The specific application of this embodiment is: when the planetary row is unevenly loaded, the planetary gear will automatically move with the shaft under force, resulting in elastic floating. When the force generated by the uneven load is balanced with the elastic force, the floating of the planetary wheel Just reach ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com