Clamping die used for sensor base drilling

A sensor and base technology, which is applied in the field of clamping molds for sensor base drilling, can solve the problems of misalignment between the workpiece hole and the positioning hole, the inability to guarantee the concentricity of the workpiece, and the failure to produce qualified products normally, so as to ensure product quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

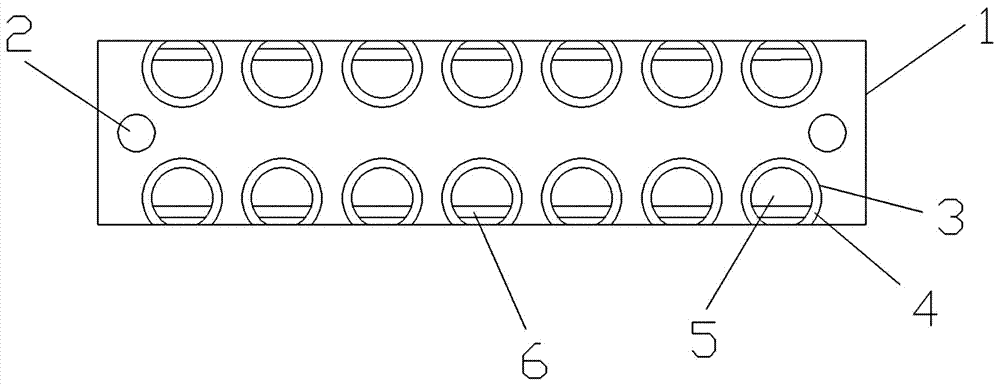

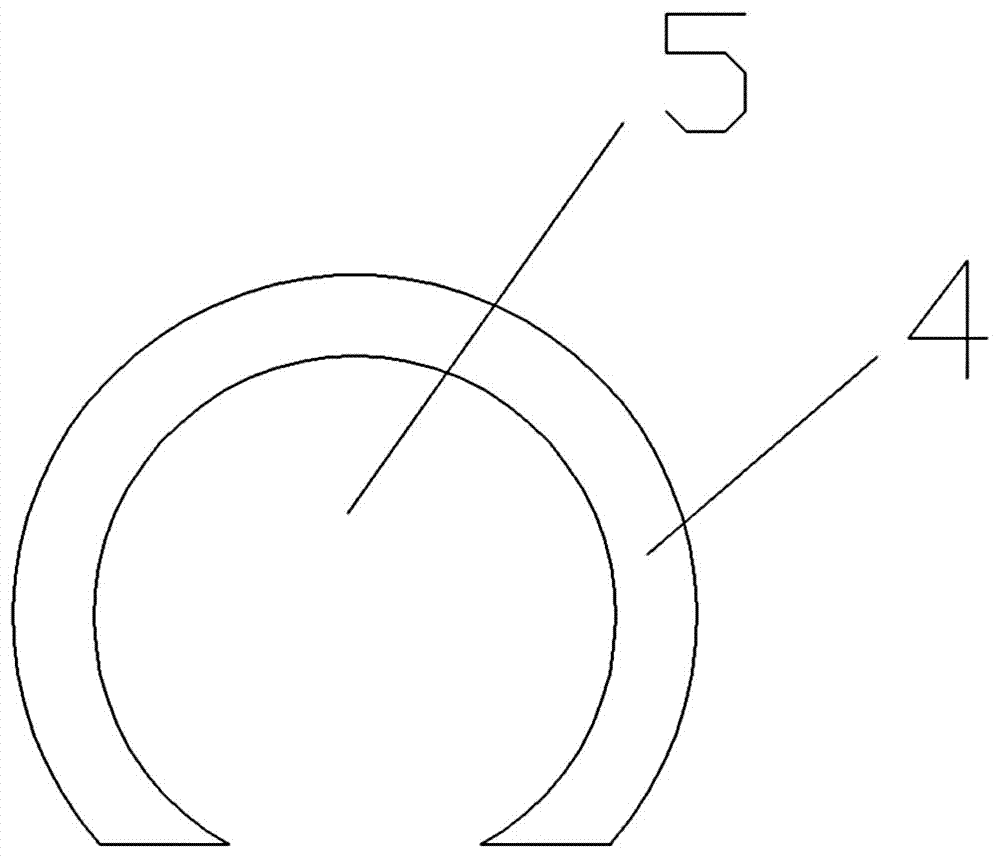

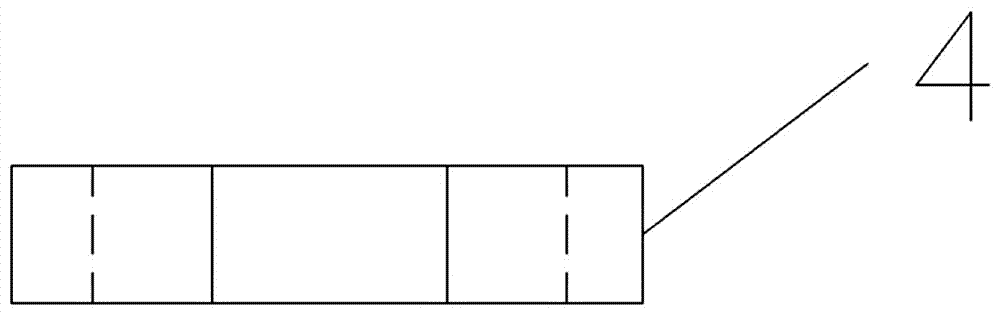

[0016] Such as figure 1 As shown, the present invention provides a clamping mold for drilling a sensor base, comprising a mold body 1 of a single-layer structure, a group of workpiece holes 3 are provided on the mold body 1, and mounting holes 2 are formed at both ends of the mold body 1. The mounting holes 2 are used to position the mold on the drilling machine; preferably, the workpiece holes are two rows arranged in parallel, and each row of workpiece holes is six; figure 2 and image 3 As shown, each workpiece hole is provided with a positioning block 4 that is interference fit with the workpiece hole, and the center of the positioning block 4 is provided with a positioning hole 5, which is concentric with the workpiece hole 3; 4 pairs of positioning blocks are placed in the workpiece hole 3 The sensor base inside achieves high positioning. combine Figure 4 and Figure 5 As shown, two fixing pins 6 are also pierced in the mold body 1, and the two fixing pins 6 respec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com