Linear motion mechanism

A linear motion and rigid technology, applied in mechanical equipment, transmission devices, friction transmission devices, etc., can solve problems such as affecting transmission accuracy and increasing economic costs, and achieve the effect of reducing costs, saving economic costs, and having a simple shape.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following is a detailed description with reference to the drawings and specific embodiments.

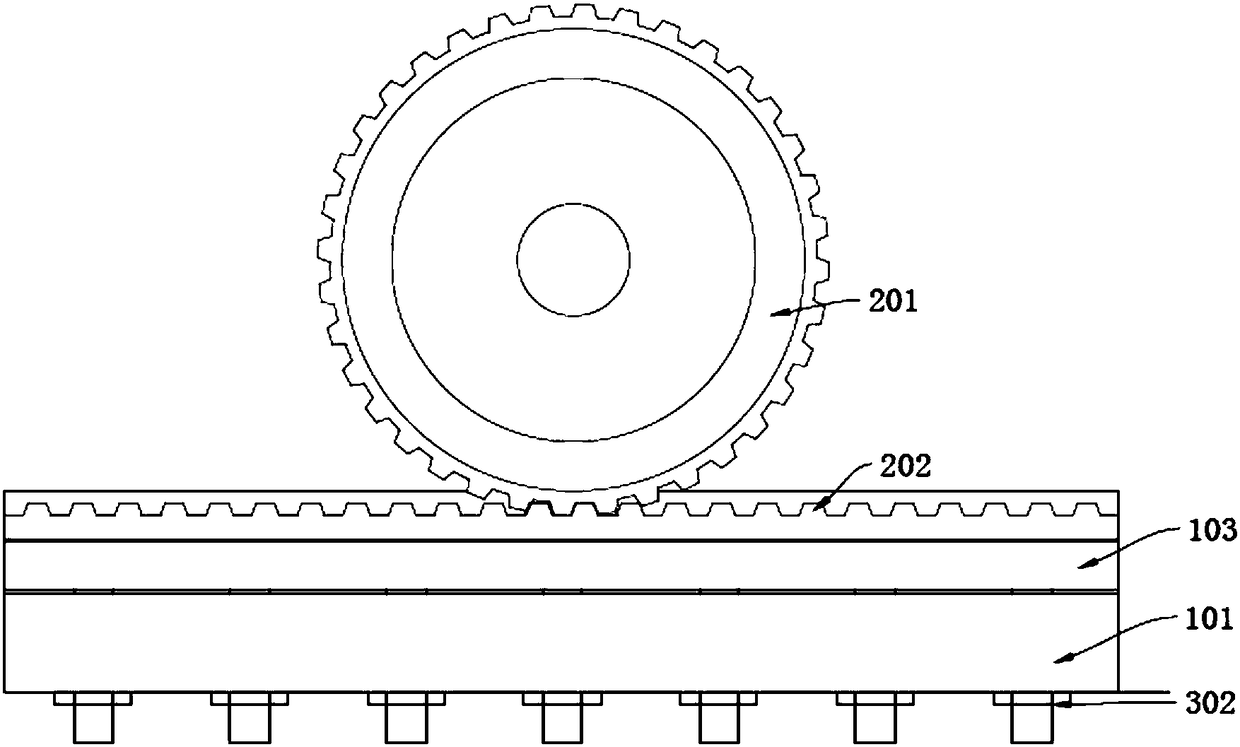

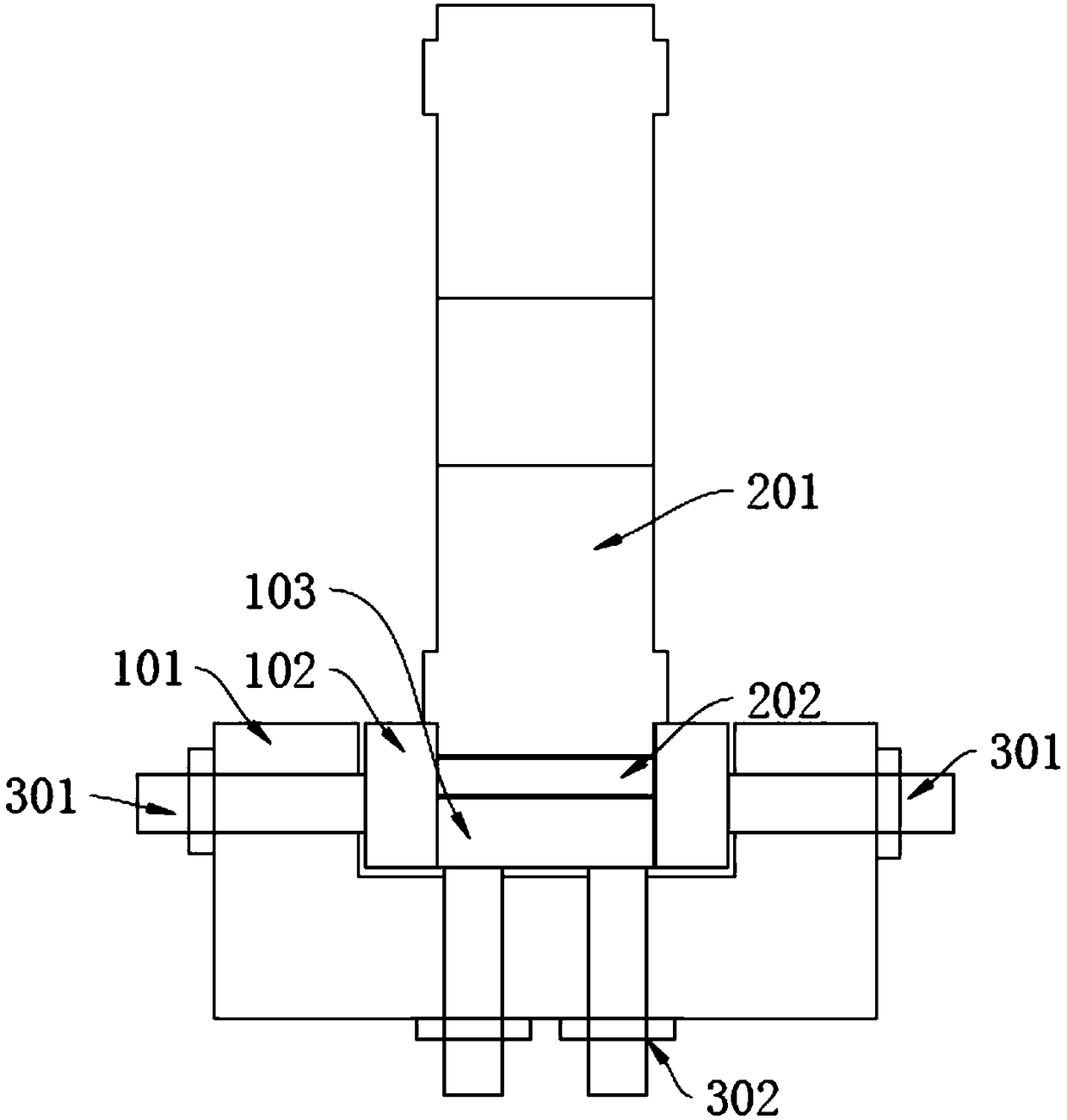

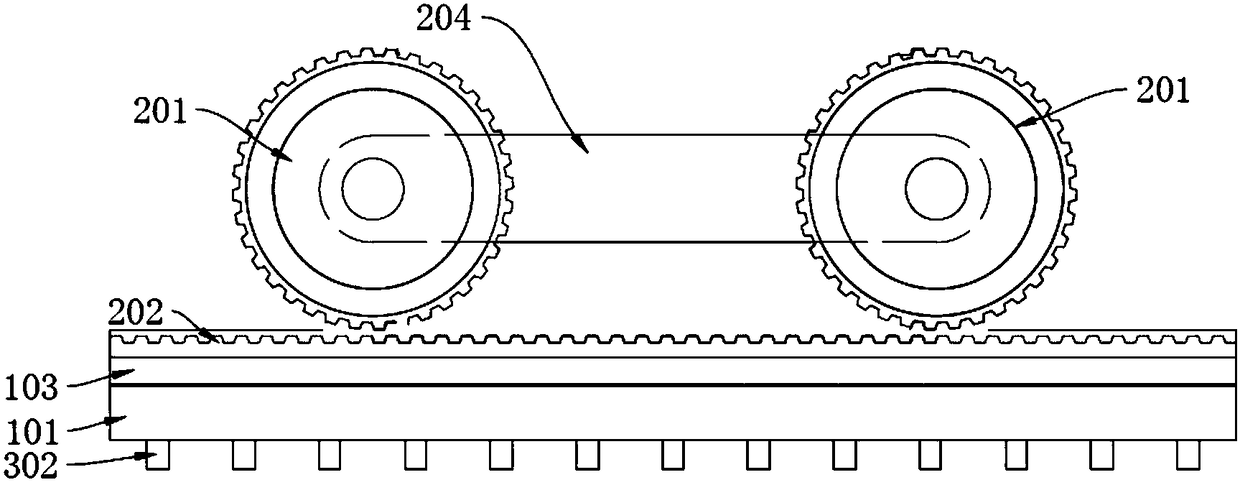

[0031] Such as Figure 1-6 As shown, a linear motion mechanism includes a first U-shaped guide rail support plate 101, a flat synchronous belt 202, and a timing belt wheel 201; wherein the middle of the first U-shaped guide rail support plate 101 is provided with a first groove along the length direction, The flat timing belt 202 is fixed on the bottom surface of the first groove, and the timing belt wheel 201 is engaged with the flat timing belt 202. The installation accuracy can be ensured by the machining accuracy of the first U-shaped guide rail support plate 101, or by Other parts are installed on the U-shaped guide rail support plate 101 for guarantee; the timing belt wheel 201 can be connected to an object such as a mounting frame or a slider, which is used to install parts that require linear motion. In this application, the synchronous belt wheel 201 and the flat sy...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com