Automatic locked centering dustproof mechanism for drilling machine

An automatic locking and drilling rig technology, which is applied in the direction of drill pipes, drill pipes, drilling equipment, etc., can solve the problems of shortening the service life of drilling rigs, large drilling rig loads, easy rocking of anchor rods, etc. To move, prolong service life, achieve the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

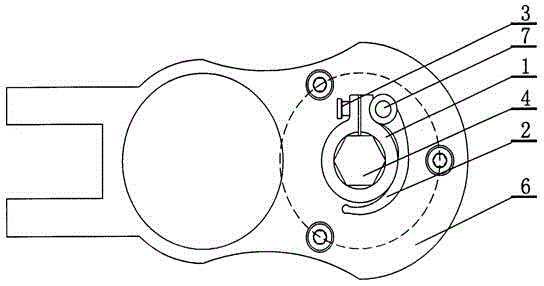

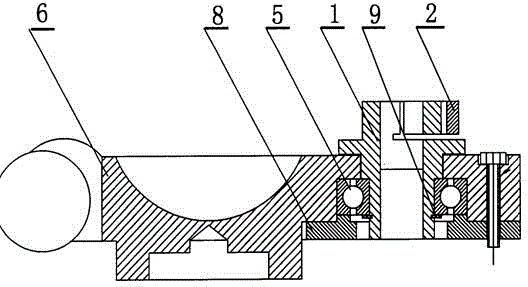

[0010] The drilling rig of the present invention uses an automatic locking centering mechanism, such as figure 1 , figure 2 As shown, there are two mutually perpendicular cracks at the upper end of the anchor sleeve 1 of the drilling rig, the locking handle 2 is arranged on the periphery of the anchor sleeve 1, the end is provided with a locking shaft 2, and the adjusting bolt 3 is arranged on the anchor At the vertical crack of the rod sleeve 1, its end face is in contact with the locking shaft 7. When the hydraulic motor drives the anchor rod sleeve 1 to rotate, the moment of inertia generated locks the anchor rod, and the hexagonal guide sleeve 4 is set in the anchor rod sleeve 1. The upper part of the anchor can be supported, protected and guided. The anchor sleeve 1 is connected and installed on the bearing seat 8 through the self-aligning bearing 5. The bearing seat 8 is coaxial with the anchor sleeve 1 and has a certain Clearance, the dustproof ring 9 is located under...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com