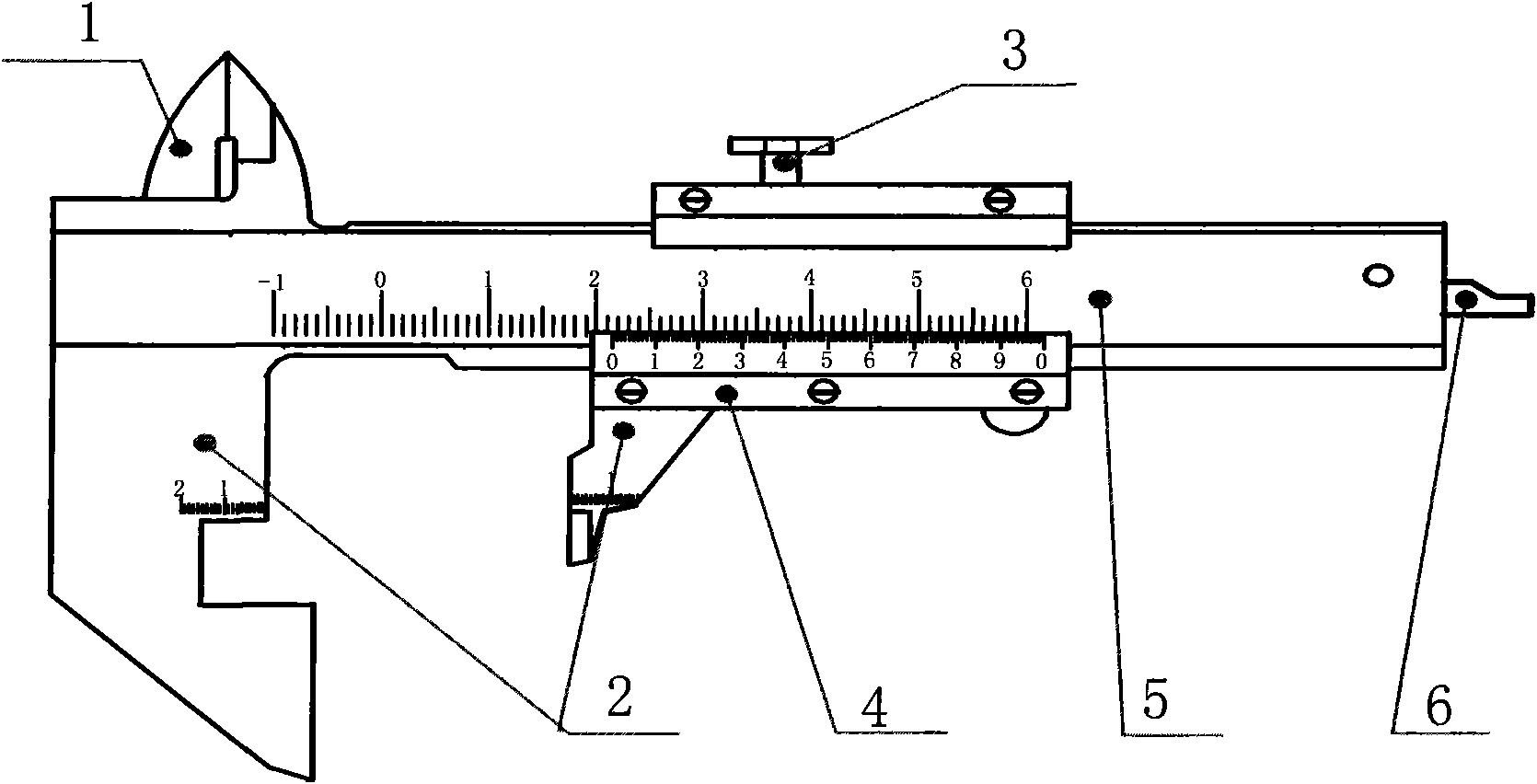

Coaxiality caliper

A technology of coaxiality and vernier calipers, which is applied in the field of multi-functional measuring tools, can solve problems such as difficulty in measuring coaxiality and symmetry, poor measurement accuracy, and limited functions, and achieve low manufacturing costs, improve accuracy, and solve measurement difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

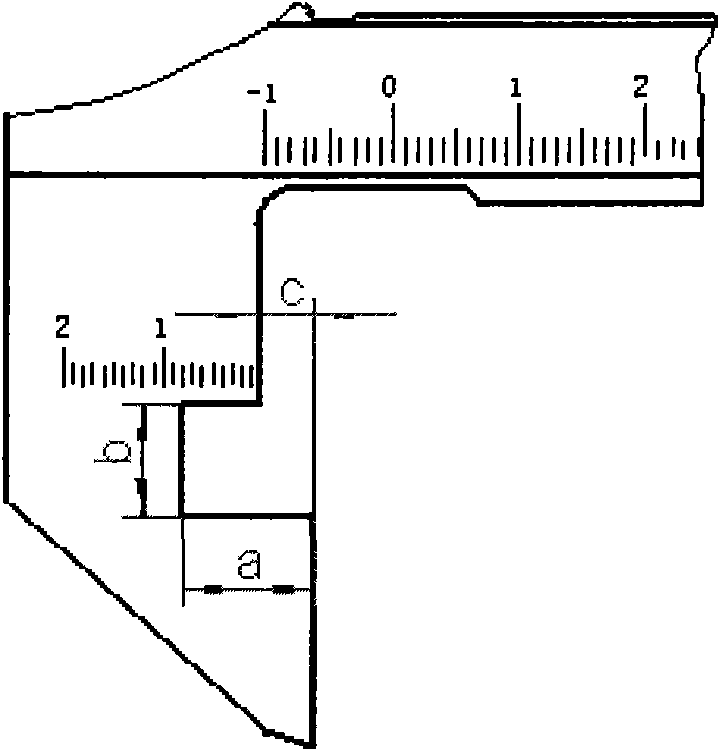

[0020] The outer measuring claw pair (2) big claw of measuring coaxiality vernier caliper described in the present invention is designed to have step rectangular shape groove, and the step width c of the bottom of groove and top is 8mm, and groove depth b is 15mm, and width a is 25mm, the outer measuring jaw pair (2) of the vernier caliper for measuring coaxiality is designed so that the measuring part is trapezoidal, the measuring head is a cone at the lower part of the trapezoid, the height E of the measuring surface is 20mm, and the width F of the measuring surface is 5mm. Mark the scale of measuring product coaxiality and symmetry on the same end face of the claw pair (2) large and small claws.

[0021] Such as Figure 8 As shown, when measuring the coaxiality of the standard product, the end of the fastener head is close to the large claw of the outer measuring claw pair (2), the fastener head is located in the groove of the large claw, and the measuring head of the small...

Embodiment 2

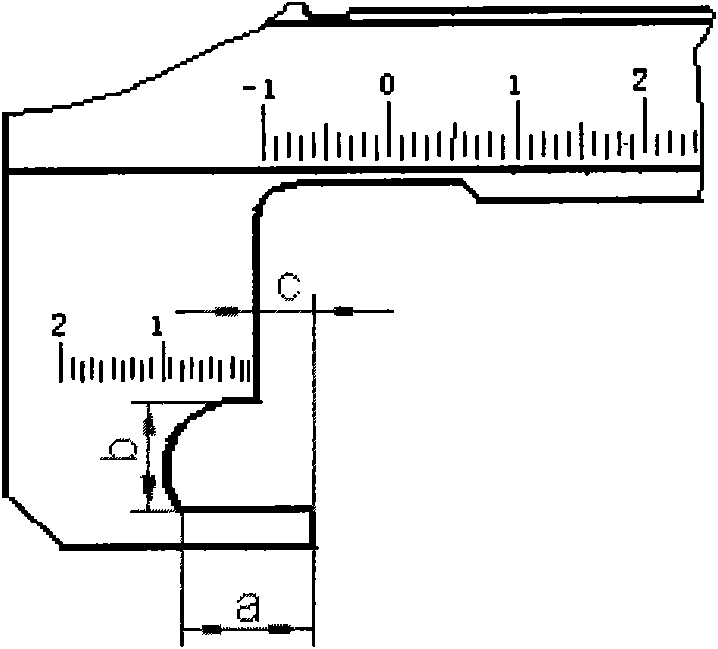

[0025] The outer measuring claw pair (2) big claw of measuring coaxiality vernier caliper described in the present invention is designed to have step rectangular shape groove, the step width c of the bottom and the top of the groove is 8mm, and groove depth b is 10mm, and width a is 15mm, the outer measuring claw pair (2) of the vernier caliper for measuring coaxiality is designed to measure the part as a trapezoid, the measuring head is a hook shape located at the lower part of the trapezoid, the height E of the measuring surface is 4mm, and the width F of the measuring surface is 5mm. claw pair

[0026] (2) The scales for measuring the coaxiality and symmetry of the product are marked on the same end surface of the large and small claws.

[0027] Such as Figure 11 As shown, when measuring the coaxiality of double-headed products, the end of the fastener head is close to the large claw of the outer measuring claw pair (2), the fastener head is located in the groove of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com