Novel needle cylinder, inner and outer sinker cam-cap and sinker cap structure of computer-controlled hosiery machine

A technology of outer sinker seat and sinker cover, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problem of constant fixed position, solve the end face beating, improve the quality of socks, and improve the fabric of socks quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings.

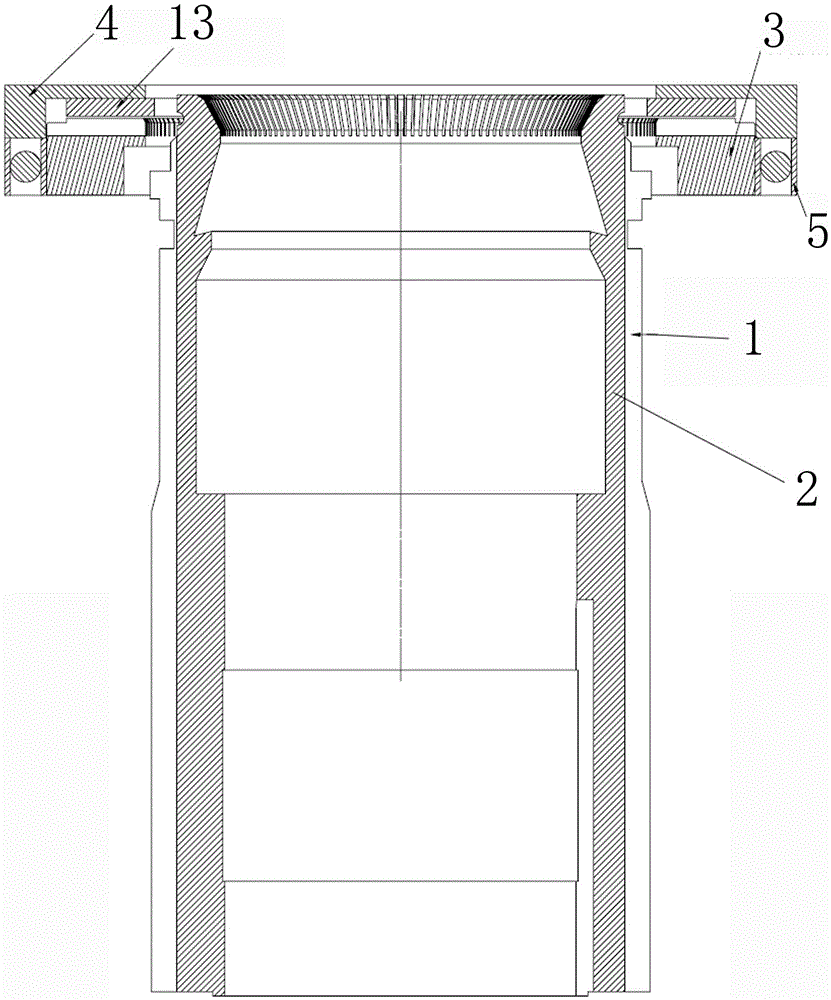

[0016] Such as figure 1 As shown, the new syringe, inner and outer sinker seat and sinker cover structure of the fully computerized hosiery machine of the present invention includes a syringe 1, an inner sinker seat 2, an outer sinker seat 3 and a sinker cover 4, and a syringe 1 , The inner sinker seat 2 is set as a whole or integrally formed, the upper part of the syringe 1 is provided with an outer sinker seat 3, the outer sinker seat 3 is sleeved with a bearing 5, and the sinker cover 4 is fixed on the outer ring of the bearing 5.

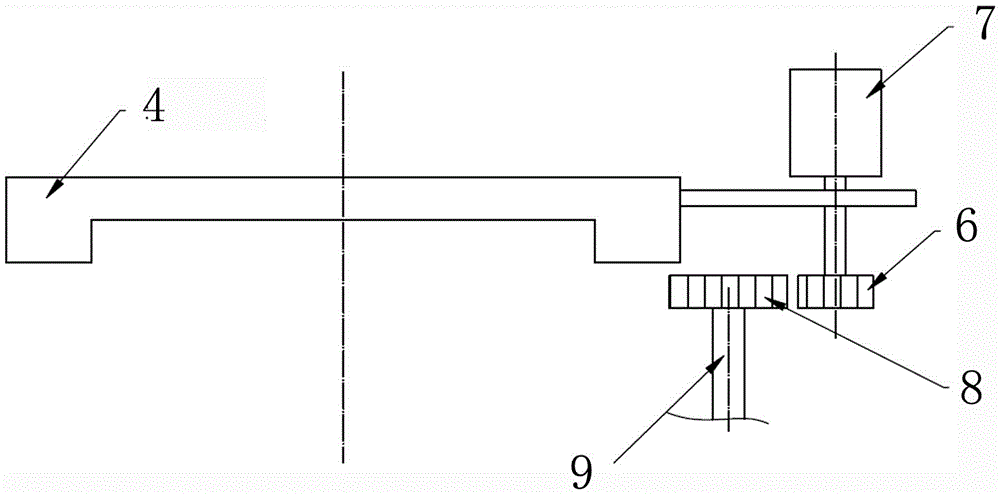

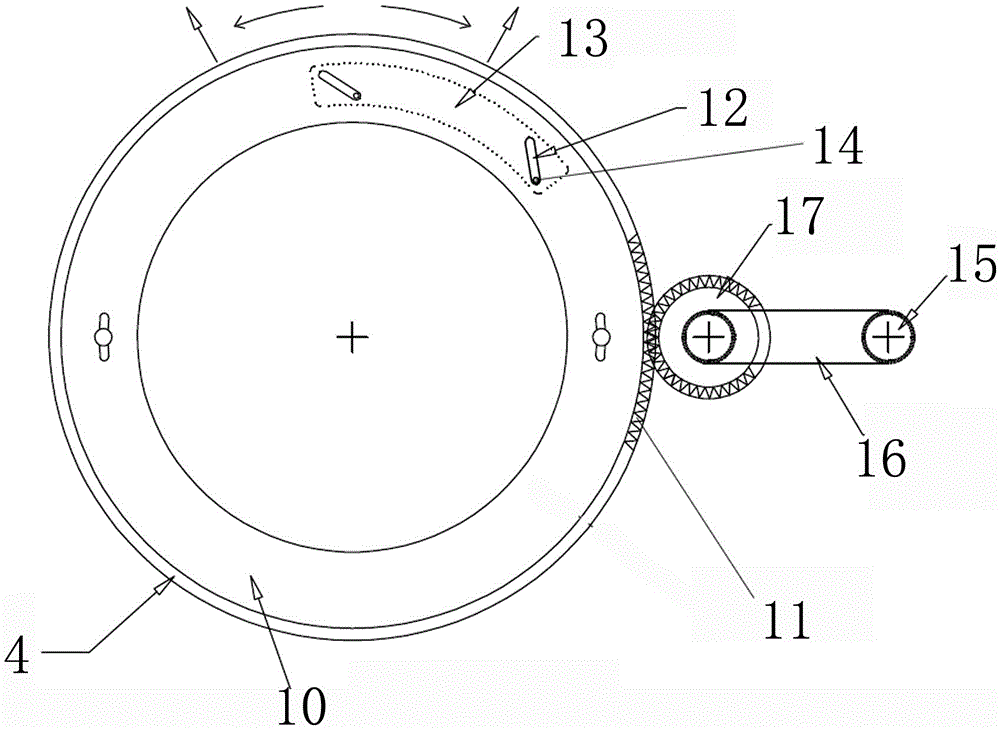

[0017] Such as figure 2 As shown, the sinker cover 4 is provided with a pinion 6 which is driven by the first stepping motor 7. The pinion 6 meshes with the half-moon gear 8, the half-moon gear 8 is arranged on the gear column 9, and the pinion 6 The rotation drives the sinker cover 4 to rotate a small angle to achieve the change of the matching position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com