Novel spinning cradle

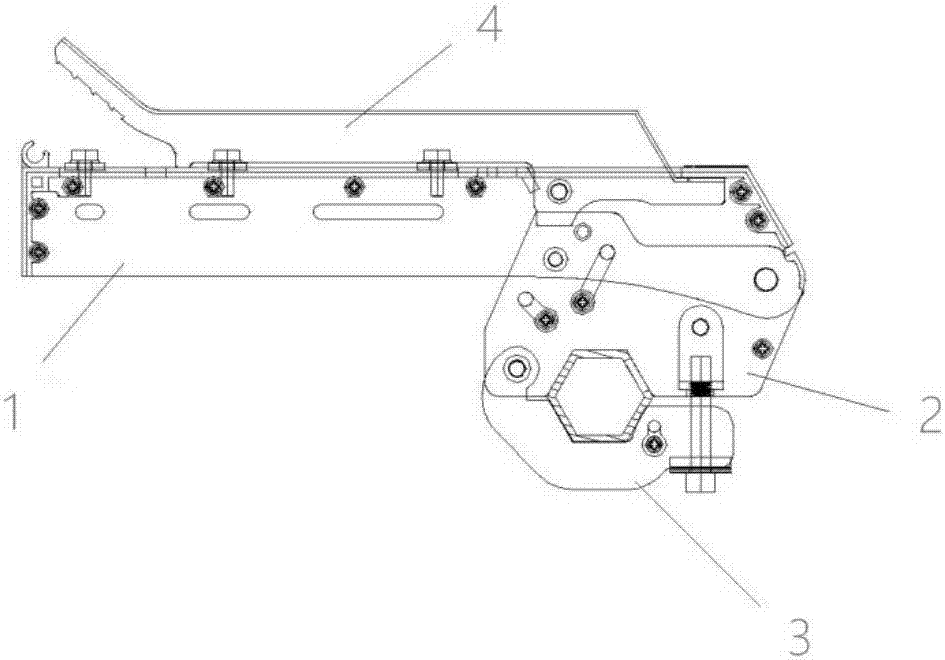

A textile cradle, a new type of technology, applied in textiles and papermaking, spinning machines, drafting equipment, etc., can solve the problems of concentricity error, difficult adjustment, complicated procedures, etc. High, simple production process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

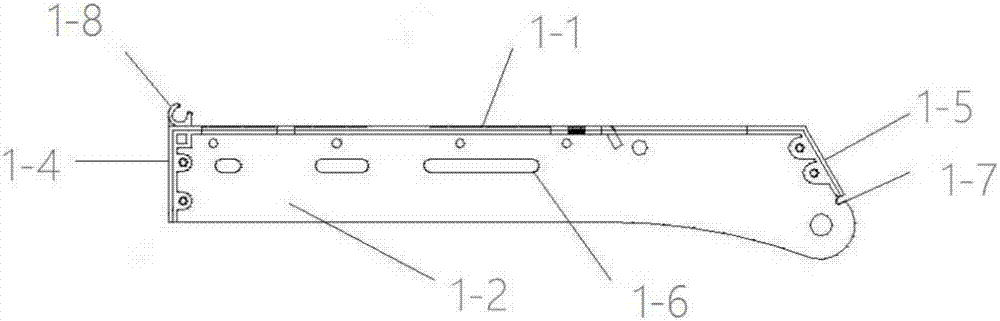

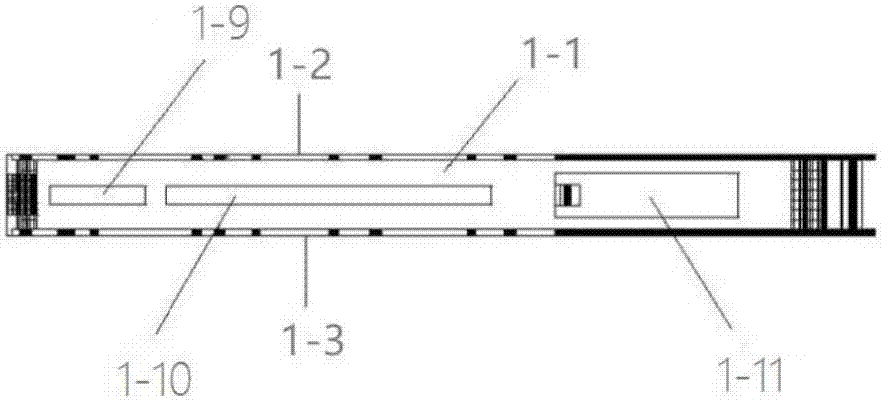

[0029] Such as Figure 2 ~ Figure 4 As shown, in the first embodiment of the housing 1 of the present invention, the side surfaces 1-2, 1-3 and the connecting surface 1-1 of the housing 1 are three mutually independent surfaces, and the three surfaces are cast separately, and the bolts, Fix the connection with screws, etc.

[0030] Wherein, the front end surface 1-4 and the rear end surface 1-5 are two extension surfaces of the connection surface 1-1, and the front end surface 1-4, the rear end surface 1-5 and the side surfaces 1-2, 1-3 are fixed by bolts or screws Connection, used to improve the stability of the housing; side 1-2 and / or side 1-3 are provided with more than one window 1-6, which can be used for pressure regulating windows or fixing devices; side 1-2, side 1-3 A U-shaped groove 1-7 is provided at the position close to the rear end surface 1-5. When the housing 1 is lifted, the U-shaped groove 1-7 plays a role in limiting the housing; the connecting surface 1-1...

specific Embodiment 2

[0033] Such as Figure 5 As shown, it is the second embodiment of the housing 1 of the present invention. The main difference from the first embodiment of the housing 1 is that the connecting surface 1-1 and the side 1-3 of the housing 1 are integrally formed, and the side 1 -2 is an independent surface, and the side 1-2 is fixedly connected with the integrally formed connecting surface 1-1 and the side 1-3 by means of bolts or bolts.

[0034] Adopting this embodiment has the following beneficial effects: the production process is simple, the concentricity is high, and mass production is possible.

[0035] The specific embodiment 1 of upper fixed card and lower fixed card

[0036] Such as Figure 6 ~ Figure 8 As shown, it is the first specific embodiment of the upper fixing card 2 of the present invention. The side surfaces 2-2, 2-3 and the connecting surface 2-1 of the upper fixing card 2 are three independent surfaces, and the three surfaces are cast separately. The conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com