Device and method for accurately measuring sediment thickness of cast-in-situ bored pile

A technology for bored piles and sediment thickness, which is used in the testing of foundation structures, construction, infrastructure engineering, etc., and can solve problems such as result correction, inaccurate starting reference points for measurement, and inability to accurately judge the upper surface of the sediment layer. , to increase the applicability, reduce the bottom pressure, and improve the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

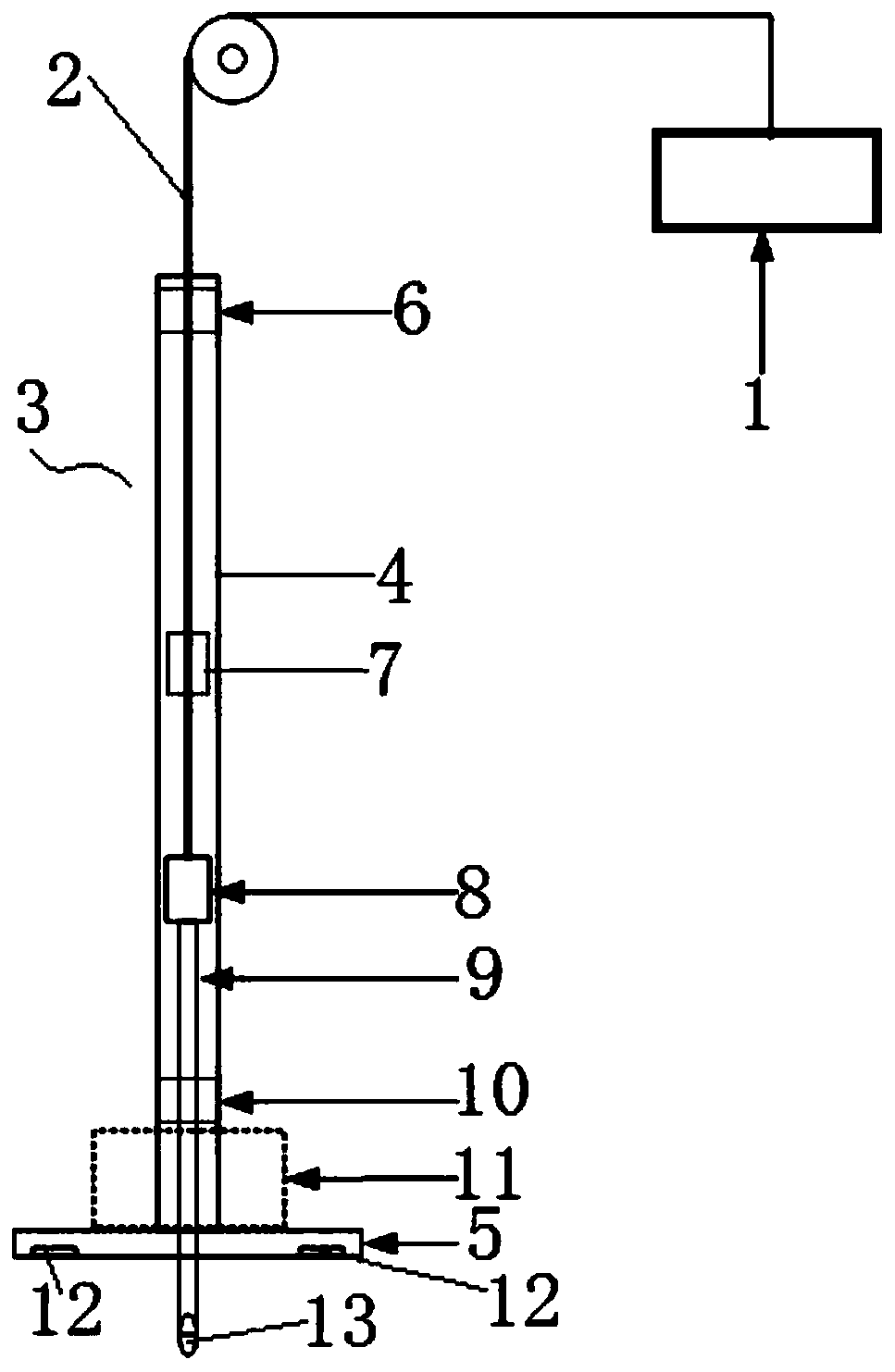

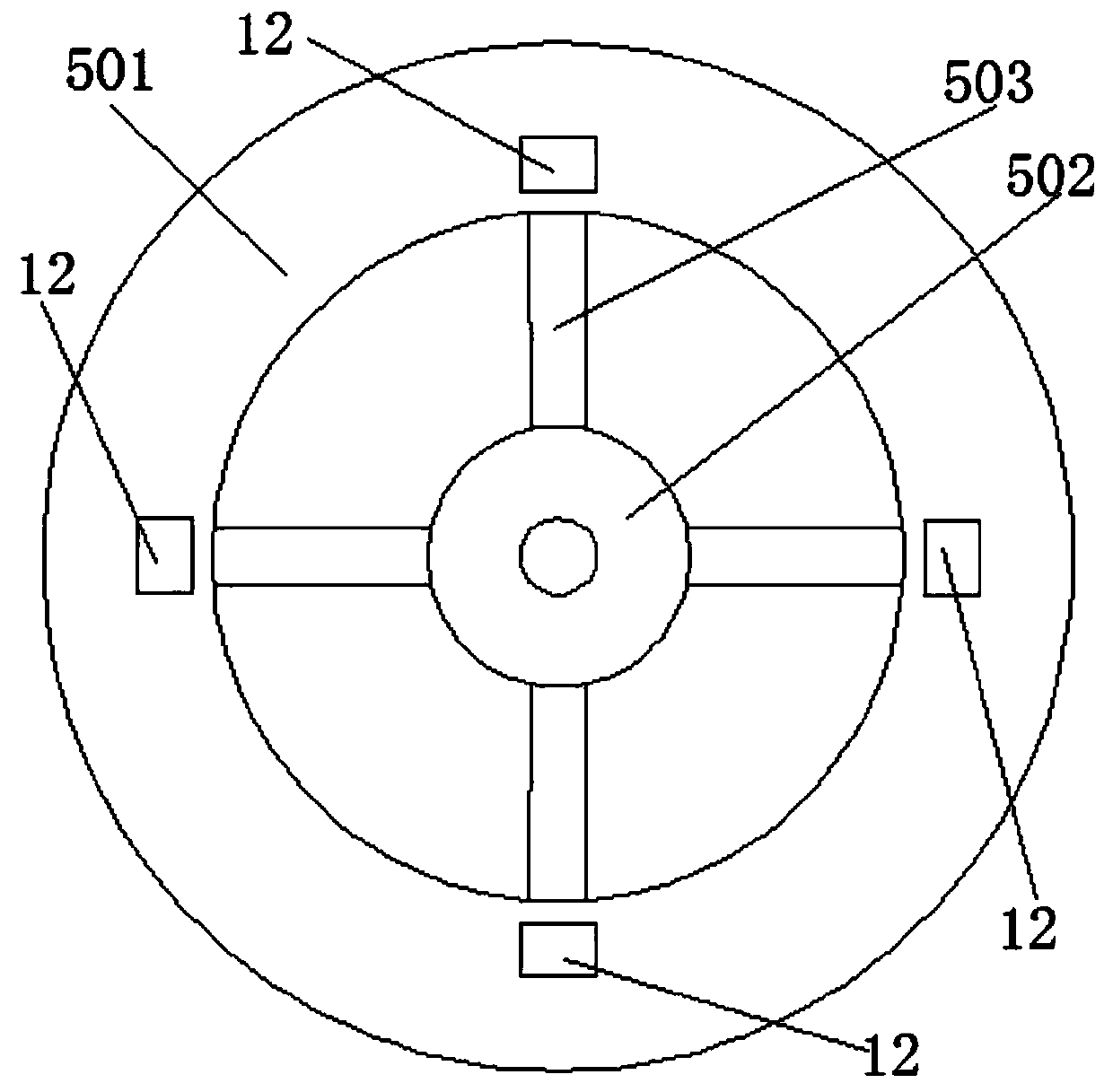

[0060] Such as figure 1 with figure 2 As shown, a device for accurately measuring the sediment thickness of bored piles includes a host computer 1 located on the ground, a sediment probe 3 connected to the host computer 1 through a cable 2, and the sediment probe 3 includes a casing 4 and Chassis 5, the casing 4 is provided with an upper seal 6, a circuit board 7, a motor 8, a mechanical probe 9 and a lower seal 10 in sequence from top to bottom, and the mechanical probe 9 passes through the lower seal 10 and the chassis 5 protrude outward; four first pressure sensors 12 are evenly distributed on the bottom surface of the chassis 5;

[0061] The end of the mechanical probe 9 is provided with a second pressure sensor 13, which is used to record the real-time pressure value entering the sediment layer until the bottom of the sediment layer; the body of the mechanical probe 9 is also provided with an angle for measuring its inclination. Sensors (not shown in the figure, embedd...

Embodiment 2

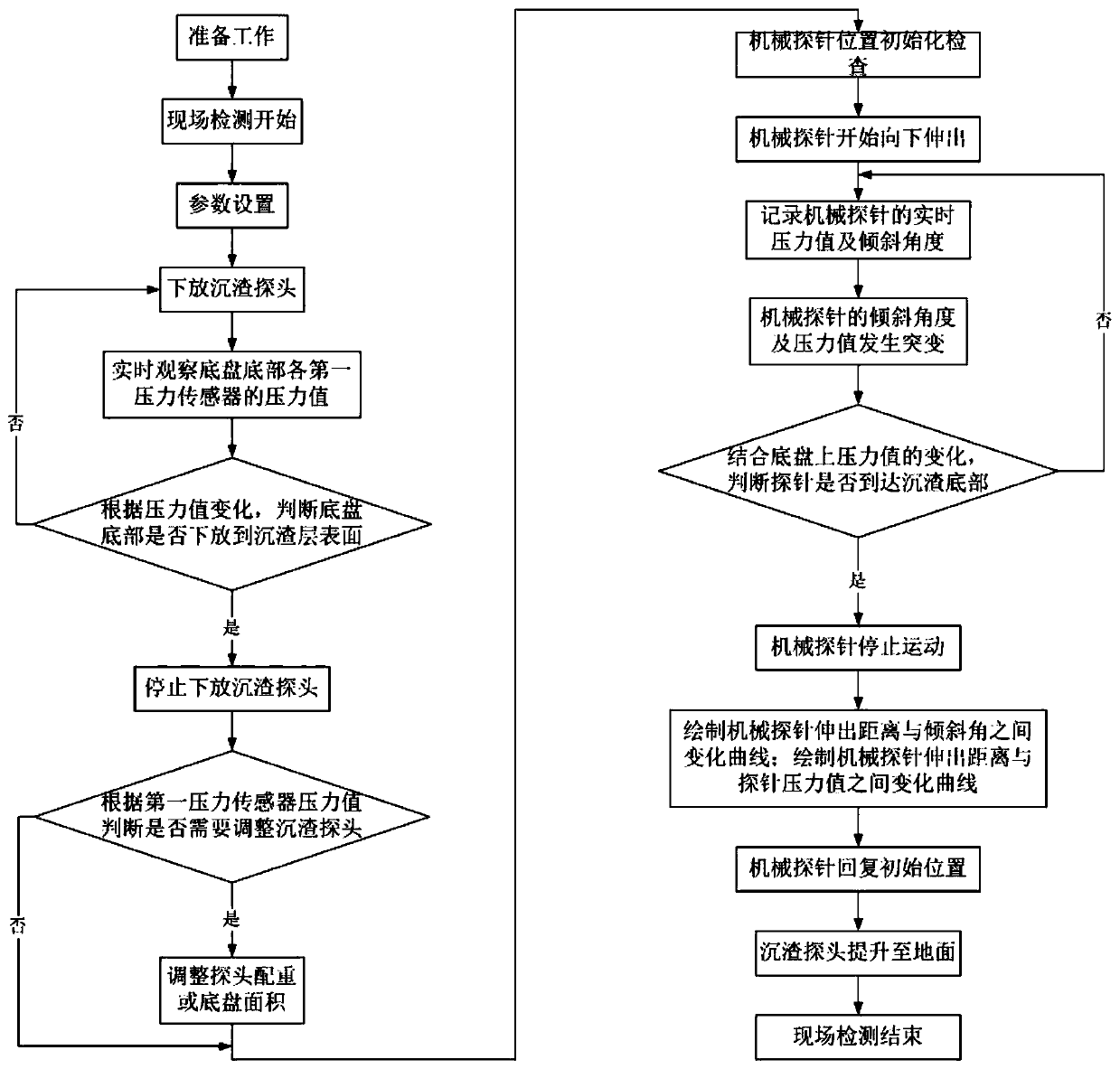

[0071] This embodiment provides a working process of the device for accurately measuring the sediment thickness of bored piles in Embodiment 1, such as image 3 Shown is the flow chart of described workflow, and described workflow comprises the following steps:

[0072] Step (1), preparatory work, test described upper computer function, collect data, set relevant parameter in described upper computer;

[0073] Step (2), controlling the winch to lower the sediment probe through the cable;

[0074] Step (3), observing and recording the numerical change of the first pressure sensor below the chassis in real time during the lowering process;

[0075] Step (4), judging whether the chassis is lowered to the upper surface of the sediment layer according to the numerical change of the first pressure sensor under the chassis; Next step; if the value of the first pressure sensor is a steady and slow rising trend, then jump to step (3) and continue to lower the sediment probe;

[0076...

Embodiment 3

[0093] This embodiment provides a measurement method with the above-mentioned device for accurately measuring the sediment thickness of bored piles, and the measurement method includes the following steps:

[0094] Step 1: Install and set the host computer and sediment probe according to the site environment; debug the host computer and prepare for detection;

[0095] Step 2: control the upper computer to release the sediment probe, observe the value changes of each first pressure sensor under the chassis, and when the vertical of each first pressure sensor tends to be stable, the sediment probe just touches the sediment layer On the upper surface, stop lowering the sediment probe;

[0096] Step 3: According to the numerical value of each of the first pressure sensors, determine whether the counterweight of the chassis needs to be adjusted through the counterweight device; maintain stable contact between the chassis and the upper surface of the sediment layer, and control the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com