Fixture for brazing of fuel manifold

A fuel manifold and brazing technology, which is applied to manufacturing tools, welding equipment, auxiliary devices, etc., can solve the problems that the flatness of the nozzle end face cannot meet the design requirements, the flatness of the parts cannot be guaranteed, and the parts cannot be used. The effect of reducing the difficulty of calibration and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the scope of protection is not limited to the description.

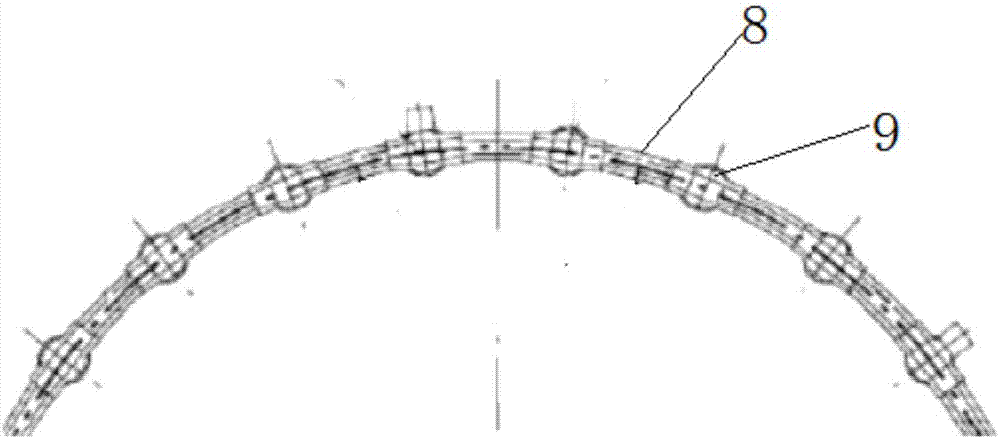

[0021] Such as image 3 As shown, it is necessary to braze the 24 nozzles 9 with gas shields to the main and auxiliary oil pipes 8, and ensure that the flatness of the 24 nozzles 9 after brazing is ≤0.3mm.

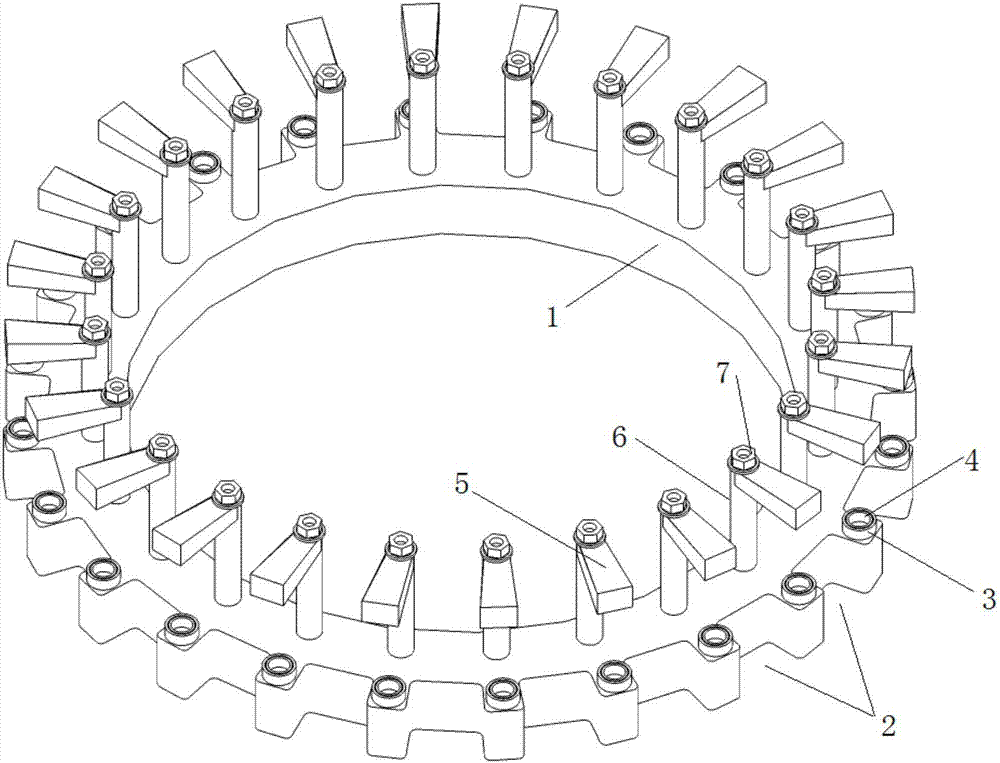

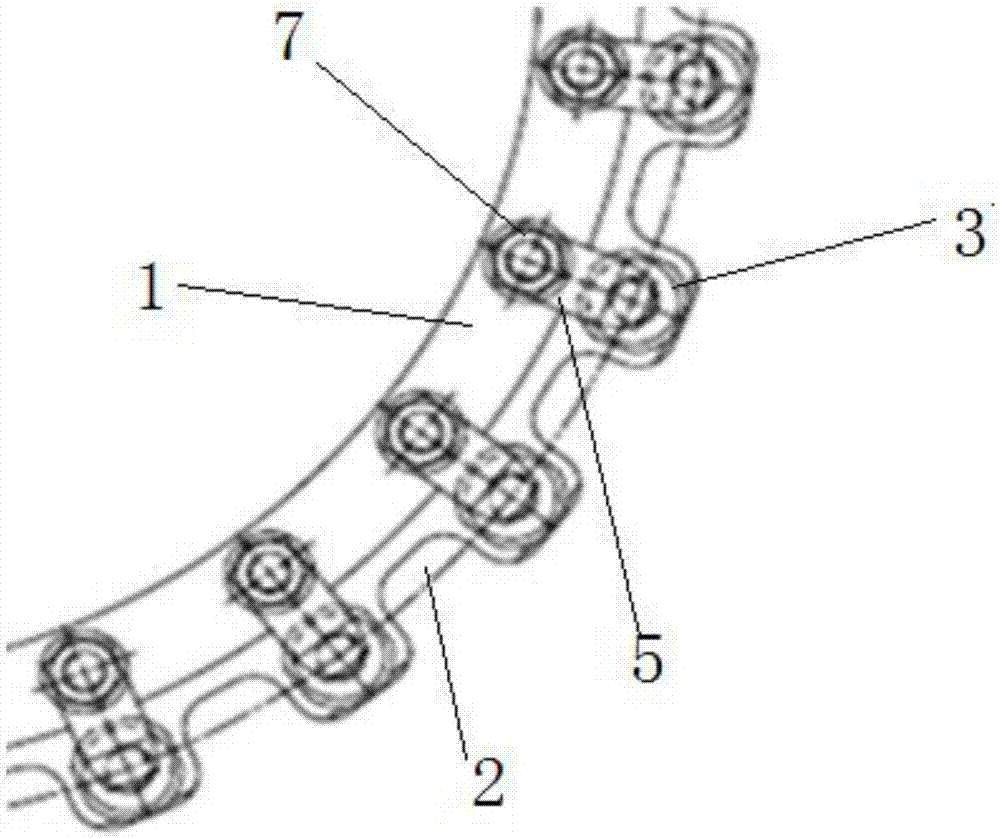

[0022] Such as figure 1 and figure 2 As shown, the fixture for brazing of the fuel main pipe includes an annular base 1, and 24 observation ports 2 are arranged at equal intervals on the outer circumference of the annular base 1 (that is, after the outer circumference is divided into equal parts, the observation ports are arranged at the positions of the equal parts. 2), the observation port 2 is a notch that runs through the base body 1 along the axis direction of the base body 1, and a support seat 3 is provided on the upper end surface of the base body 1 between the notches, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com