Device for installing cylindrical flange

A flange-mounted, cylindrical technology, used in workpiece clamping devices, aircraft assembly, hand-held tools, etc., can solve the problems of poor plane verticality, cylindrical barrel section, and poor camber fit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

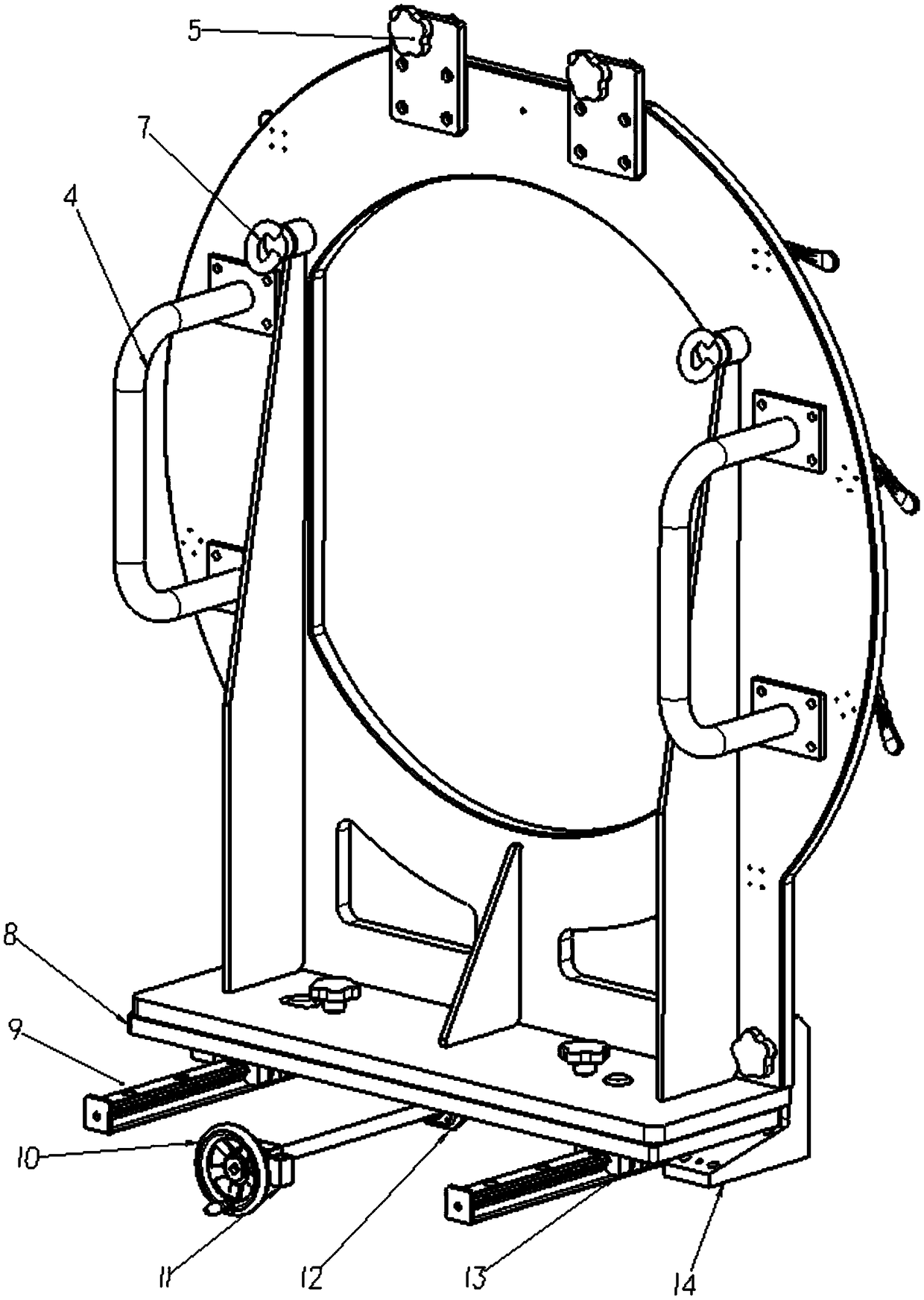

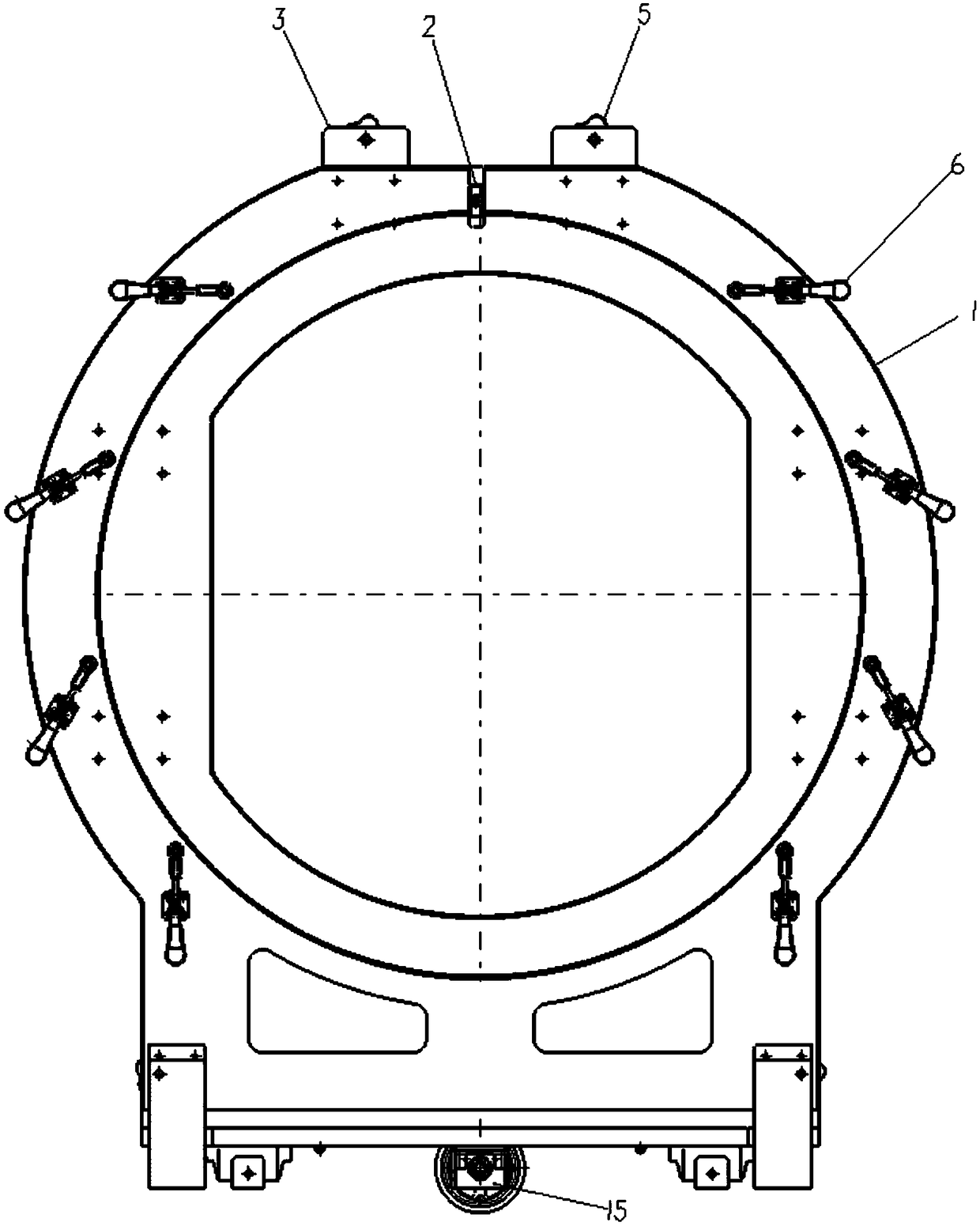

[0013] This embodiment is a device for cylindrical flange installation.

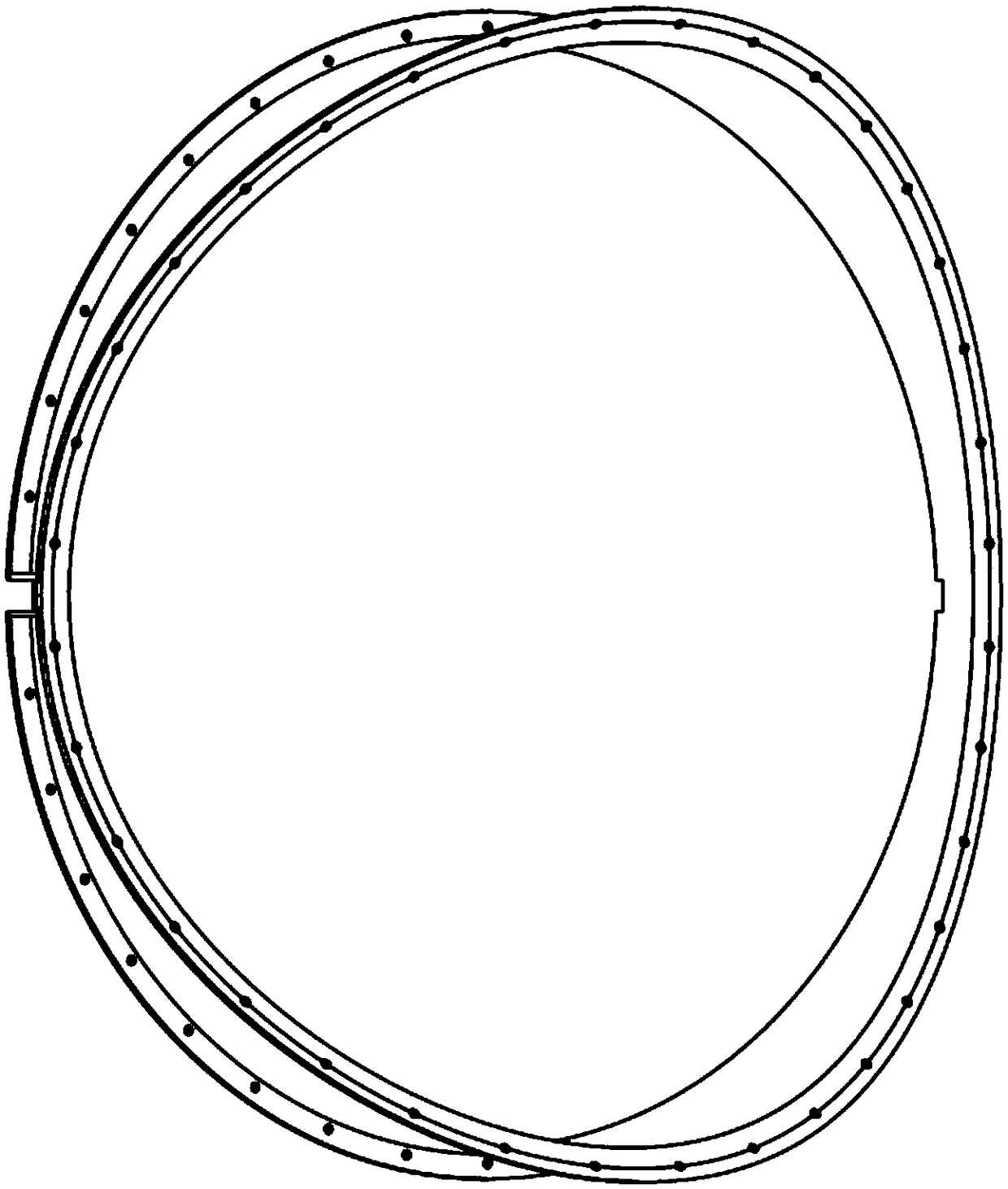

[0014] refer to figure 1 , figure 2 , a device for installing a cylindrical flange, which includes a mounting mechanism and a transmission mechanism, wherein the mounting mechanism includes: mounting angle seat 1, positioning block 2, positioning plate 3, handle 4, handle screw 5, horizontal clamp Clamp 6, lifting ring 7, install corner seat 1 as the installation platform, handle 4 and positioning plate 3 are fixed on the rib side of the corner seat 1, so that the handle 4 and the side of the bottom plate of the corner seat 1 form a plane, handle screws 5 Embedded in the threaded hole of the positioning block 2, the lifting ring 7 is embedded in the threaded hole of the installation angle seat 1, the positioning block 2 and the horizontal clamp 6 are fixed on the other side of the installation angle seat 1, and the positioning block 2 is located on the installation angle seat 1 At the position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com