One-time clamping symmetrical turning method and device for glass die

A technology of glass mold and turning processing, which is applied in the field of metal product processing, can solve problems affecting coaxiality, etc., and achieve the effects of high processing efficiency, small footprint and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the examples, but not as a limitation of the present invention.

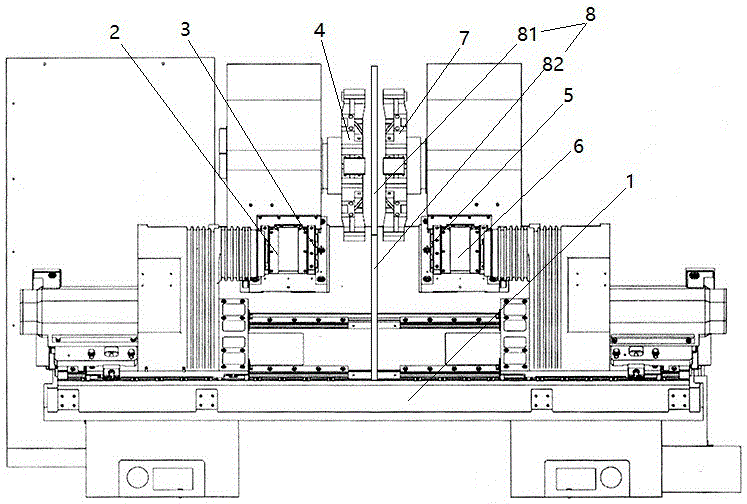

[0013] See figure 1 , the one-time clamping symmetrical turning device for glass molds involved in the present invention includes a frame 1, a first drive shaft 2, a first chuck 3, a first tool tower 4, a second drive shaft 5, and a second chuck 6 and the second tool tower 7. Wherein the first drive shaft 2 and the second drive shaft 5 are driven by respective servo motors, and are arranged symmetrically at both ends of the frame 1, and a plurality of cutters can be arranged on the first tool tower 4 and the second tool tower 7 to accommodate Different processing needs. The first chuck 3 is arranged on the first drive shaft 2 and is driven to rotate by the first drive shaft 2. The first tool turret 4 is arranged on the same side of the first chuck 3, and the feeding direction of the first tool turret 4 is perpendicular to The rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com