Precision gang tool level bed numerically controlled lathe with tailstock

A technology of CNC lathe and flat bed, which is applied in the direction of tailstock/top, automatic lathe/semi-automatic lathe, turning equipment, etc. It can solve the problems of inability to process shaft parts, high failure rate of headstock unit, difficulty in processing and installation, etc. problem, to achieve the effect of simple structure, lower purchase cost and guaranteed quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

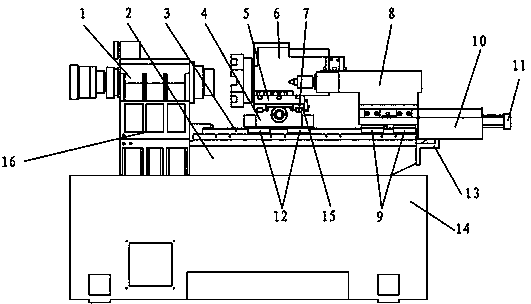

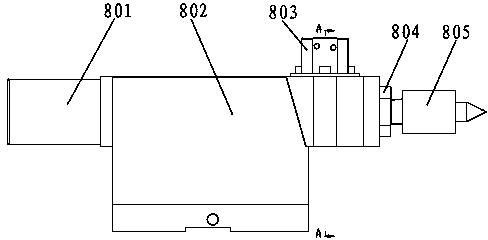

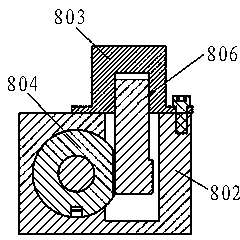

[0016] As shown in the figure, a CNC lathe with a precision row of tailstocks and a flat bed includes a base 14 on which a headstock seat 16 is fixed, and a headstock unit 1 is fixed on the headstock seat 16 . The spindle box unit 1 includes a spindle box 105 and a spindle unit 107 arranged in the spindle box 105, a spindle pull rod 108 is arranged in the spindle unit 107, a pneumatic rotary cylinder 101 is fixedly arranged at the rear end of the spindle unit 107, and an elastic collet is fixedly arranged at the front end of the spindle pull rod 108 106 , the rear end of the main shaft pull rod 108 is fixedly connected with the cylinder piston 109 of the pneumatic rotary cylinder 101 through the provided connecting nut 102 . The main shaft unit 107 includes a main shaft 1075 and a main shaft sleeve 1073 sleeved outside the main shaft 1075. The front and rear ends of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com