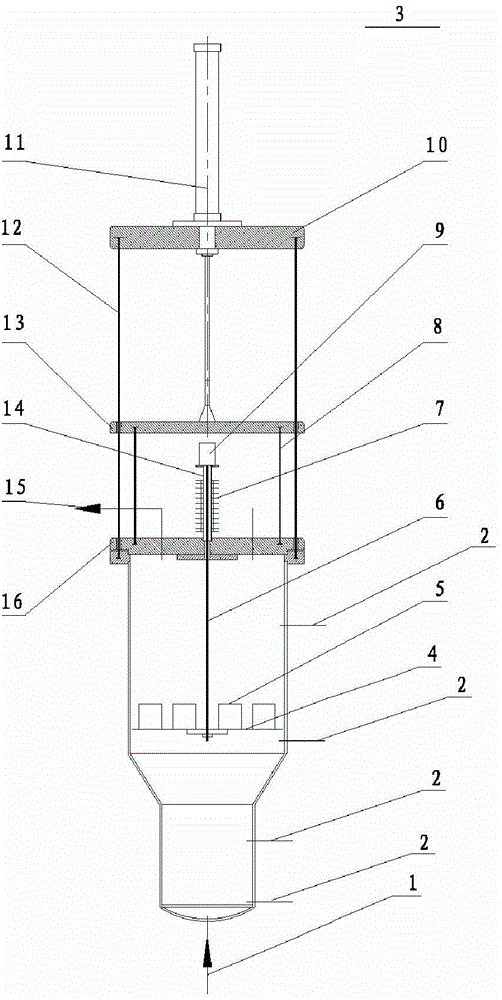

Suspended rotary catalyst ageing oven

An aging furnace and catalyst technology, which is applied in the preparation of test samples and other directions, can solve the problems of poor manufacturability, high precision required for coaxiality, and reduced operating safety of the device, and achieves low cost, increased safety, and compact structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

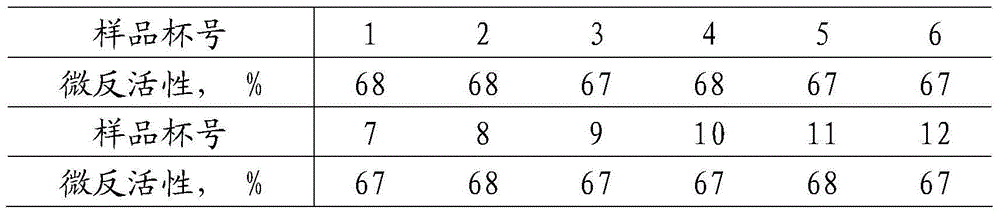

[0040] Aging results of the same catalyst sample in different sample cups

[0041]In 12 sample cups made of 60 ml porous ceramic materials, 40 grams of MLC-500 industrial fresh full sieve (0-150 μm) catalysts were all filled, under 100% water vapor, the aging temperature was 800 ° C, and the aging time was 17 hours. Under the condition that the pressure is normal pressure, the influence of the microreactive activity after aging of 12 (one layer) samples in the rotary aging furnace was investigated. The results are shown in Table 1.

[0042] Table 1 Microreactive activity after rotation aging under the same conditions

[0043]

Embodiment 2

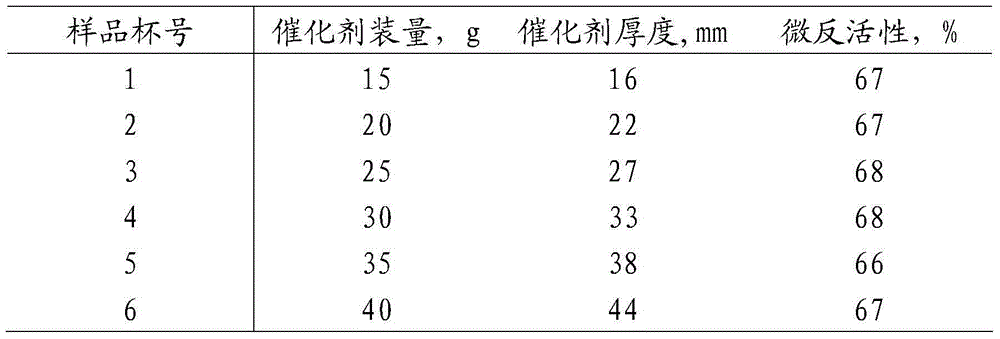

[0045] Effect of Catalyst Packing Thickness on Aging Results

[0046] In 6 sample cups made of 60 milliliters of porous ceramic materials, fill respectively 15, 20, 25, 30, 35, 40 grams of MLC-500 industrial fresh full screening (0 ~ 150 μm) catalyst, under 100% steam, Under the condition of aging temperature of 800℃, aging time of 17 hours and normal pressure, the effect of catalyst packing thickness on aging results was investigated. The results are shown in Table 2.

[0047] Table 2 Effect of catalyst packing thickness on aging results

[0048]

Embodiment 3

[0050] Rotation Aging Repeatability Investigation Test Results

[0051] The loading of the catalyst is 30 grams, 800° C., 100% water vapor, aging for 17 hours, and the pressure is normal pressure. The test results are shown in Table 3.

[0052] Table 3 Rotation aging repeatability inspection test results

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com