Plastic packaging stator module

A technology of plastic-encapsulating stators and components, applied in electric components, electrical components, magnetic circuit static parts, etc., can solve the problems of shortening the service life of the inner bearing of the outer rotor motor, affecting the working performance of the outer rotor motor, and assembly errors, etc. Increase, increase strength and toughness, improve the effect of arc resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

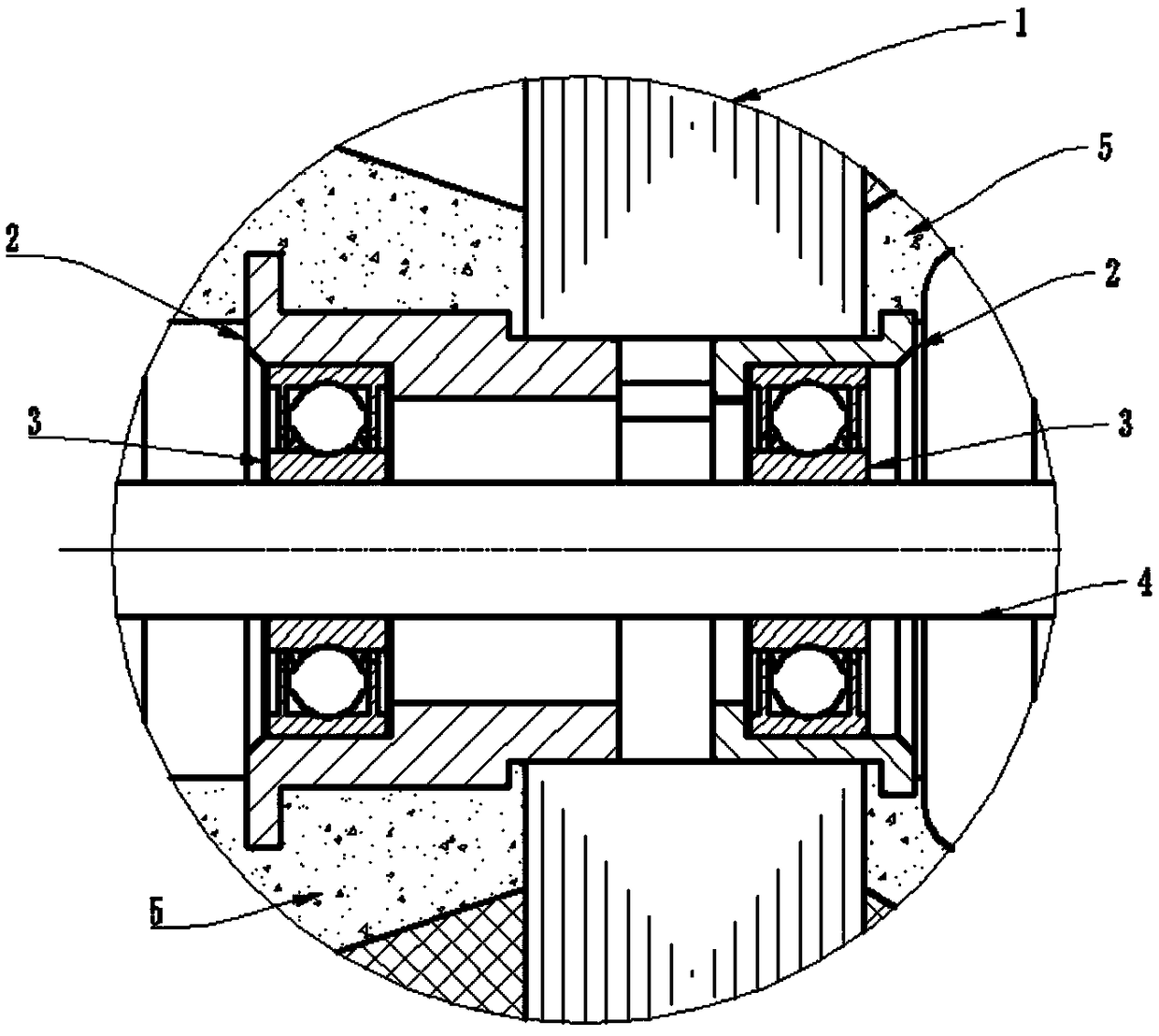

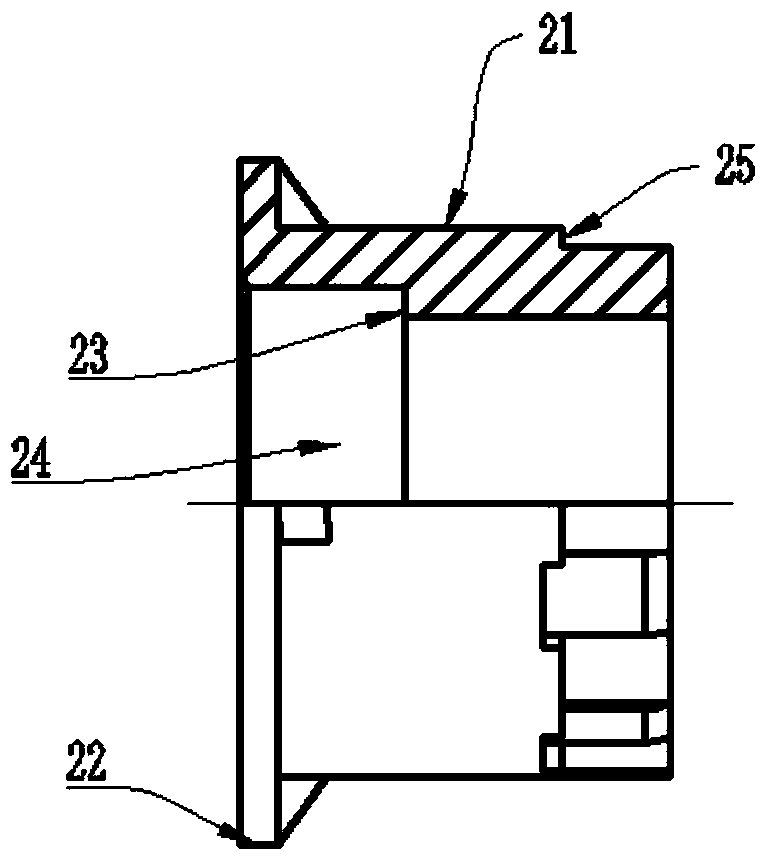

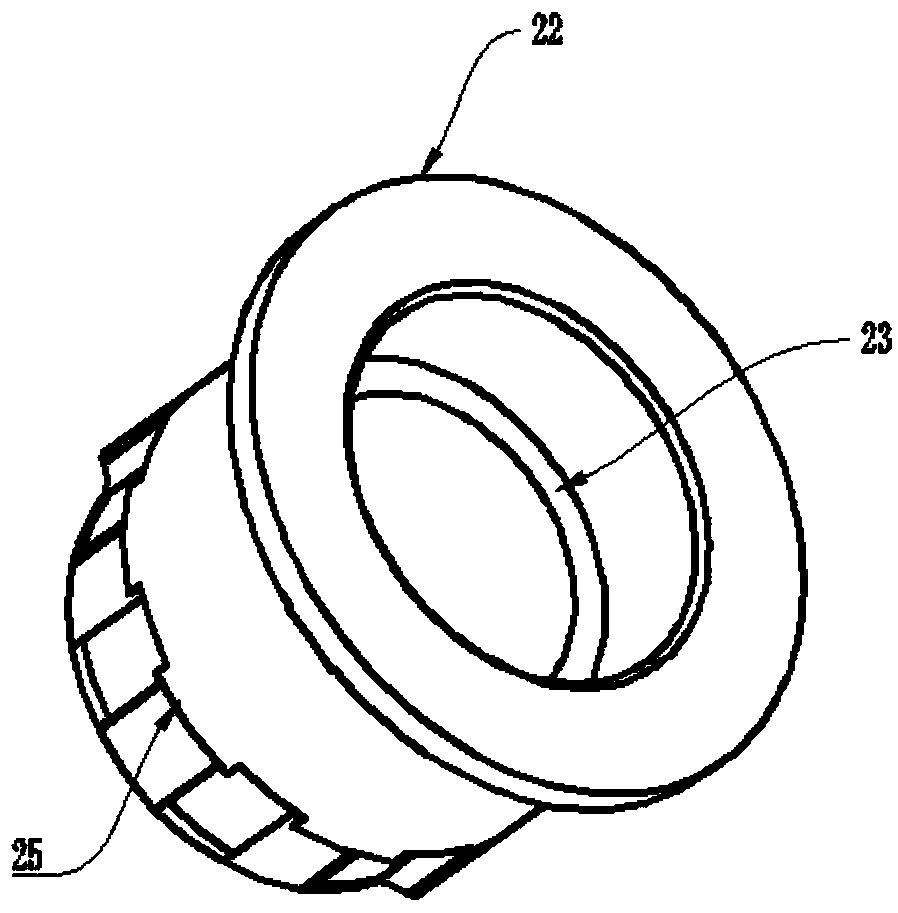

[0029] according to Figure 1-3 As shown, a plastic-sealed stator assembly includes a stator core 1 and a rotating shaft 4 located inside the stator core 1. The axis lines of the stator core 1 and the rotating shaft 4 coincide, and the two sides of the stator core 1 are respectively There is a bearing bracket 2 nested on the inner circle of the stator core 1. The bearing bracket 2 is respectively provided with a bearing 3 for transition fit with the rotating shaft 4. The stator core 1 and the bearing bracket 2 are connected through a thermosetting plastic 5. Package and plastic seal to form an integrated plastic-sealed stator assembly.

[0030] In the prior art, parts such as the bearing bracket 2, the bearing 3, the rotating shaft 4 and the stator core 1 on the outer rotor motor will have processing errors during the processing, and then the processed parts will be assembled. Due to the different assembly standards, During the assembly process, there will be assembly errors....

Embodiment 2

[0036] The content of this embodiment is basically the same as the content of Example 1, and the similarities are not repeated, and the difference is that the nano-modified talcum powder is prepared through the following steps:

[0037] (1) First roast the talc at 400-600°C for 4-5 hours, then soak the talc in 15-20% hydrogen peroxide for 4-5 hours, let stand, centrifuge, then wash and dry with deionized water, add equivalent Its weight is 3-5% of vinyltriethoxysilane, 2-3% of cross-linking agent TAC, stirred at a high speed of 3000-4000 rpm, dried and pulverized into fine powder to obtain a preliminary modified product;

[0038] (2) Put the preliminary modification prepared in the step (1) into the single-screw extrusion extruder, add sodium hexametaphosphate and surface modifier, set the screw speed to be 200~300r / min, and the expansion temperature is 60-80°C, extruding for 5-10 minutes to obtain modified talc powder;

[0039] (3) Send the modified talcum powder obtained in...

Embodiment 3

[0042] The content of this embodiment is basically the same as that of Example 2, and the similarities will not be repeated. The difference is that the thermosetting plastic preparation method is prepared through the following steps:

[0043] (1) Add the unsaturated polyester resin, additives, crosslinking agent, and inert filler into a high-shear mixer and stir evenly, and the mixing temperature reaches 60°C to prepare the resin premixed slurry;

[0044] (2) Put the premixed slurry into a Z-type reamer mixer or a planetary mixer, add the dried glass fiber, stir for 10 to 15 minutes, pour out the dough, and extrude it into Strips and pills, sealed with Mylar film after drying, and stored for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com