Automatic detection line of liquefied petroleum gas cylinder valve

A technology for automatic detection of petroleum gas cylinders, applied in liquid tightness measurement using liquid/vacuum degree, measurement device, testing of mechanical parts, etc., can solve the problems of inability to realize production automation, low efficiency of manual detection, and quantitative leakage and other problems to achieve the effect of eliminating unsafe hidden dangers, improving efficiency and speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

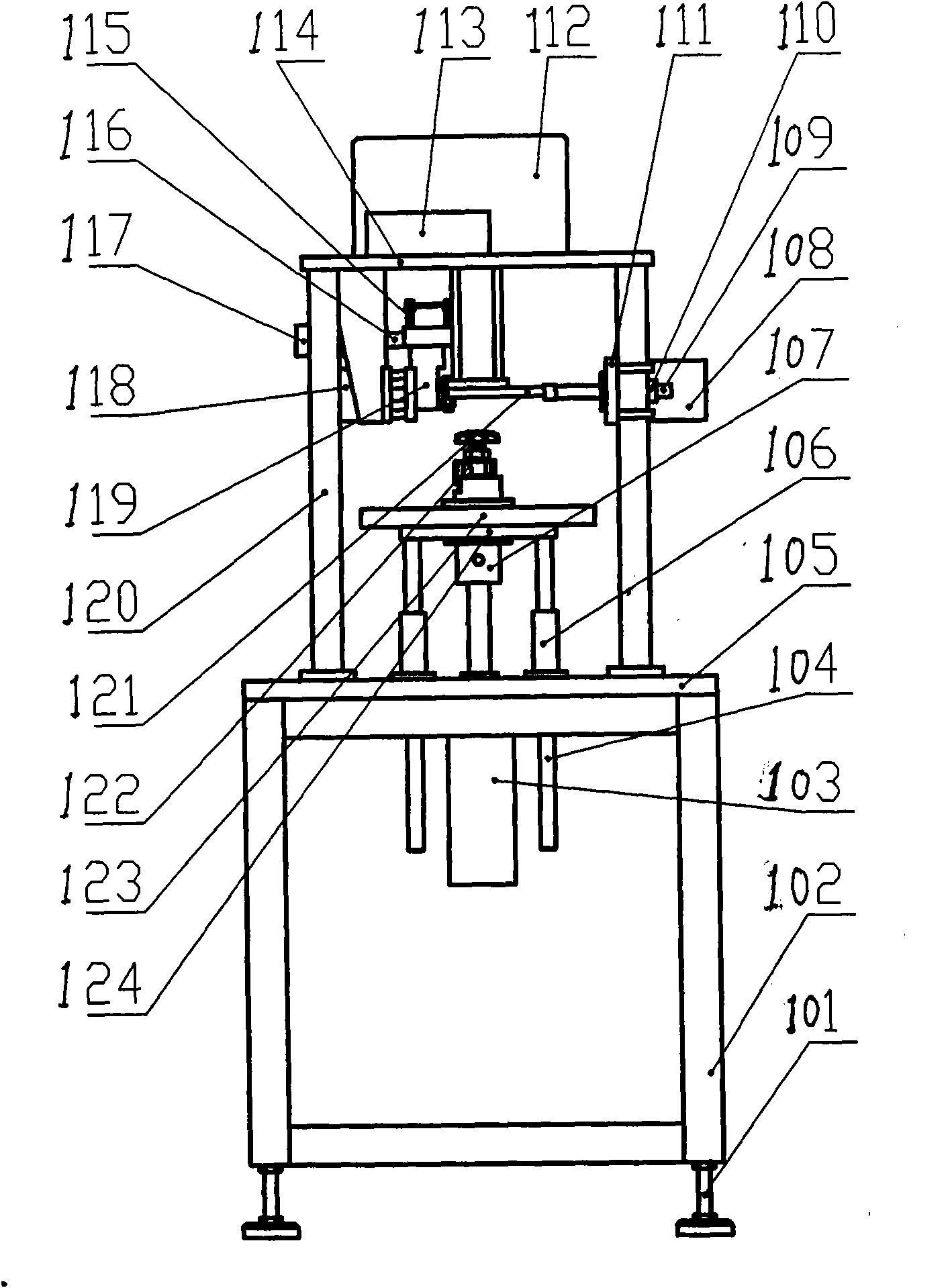

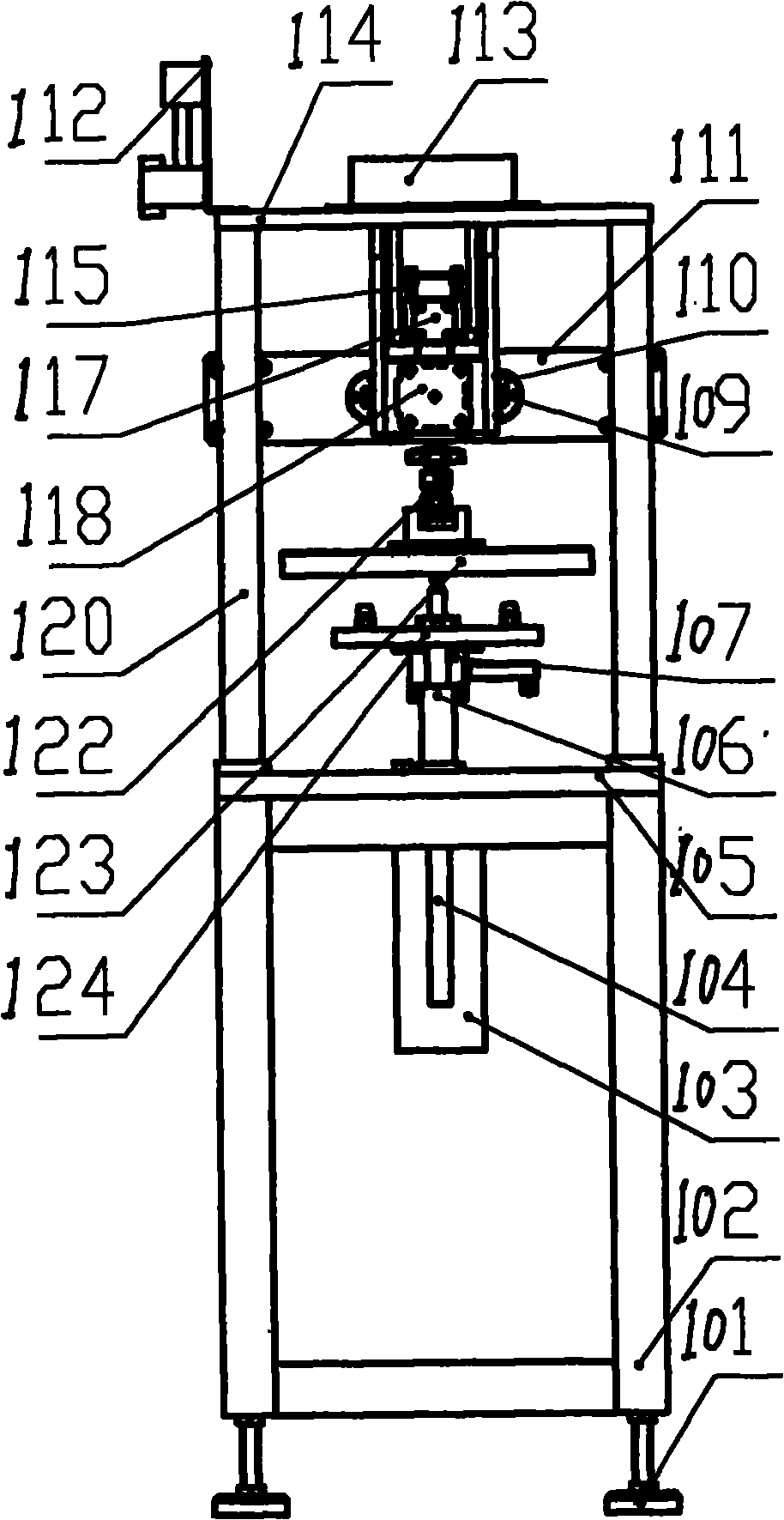

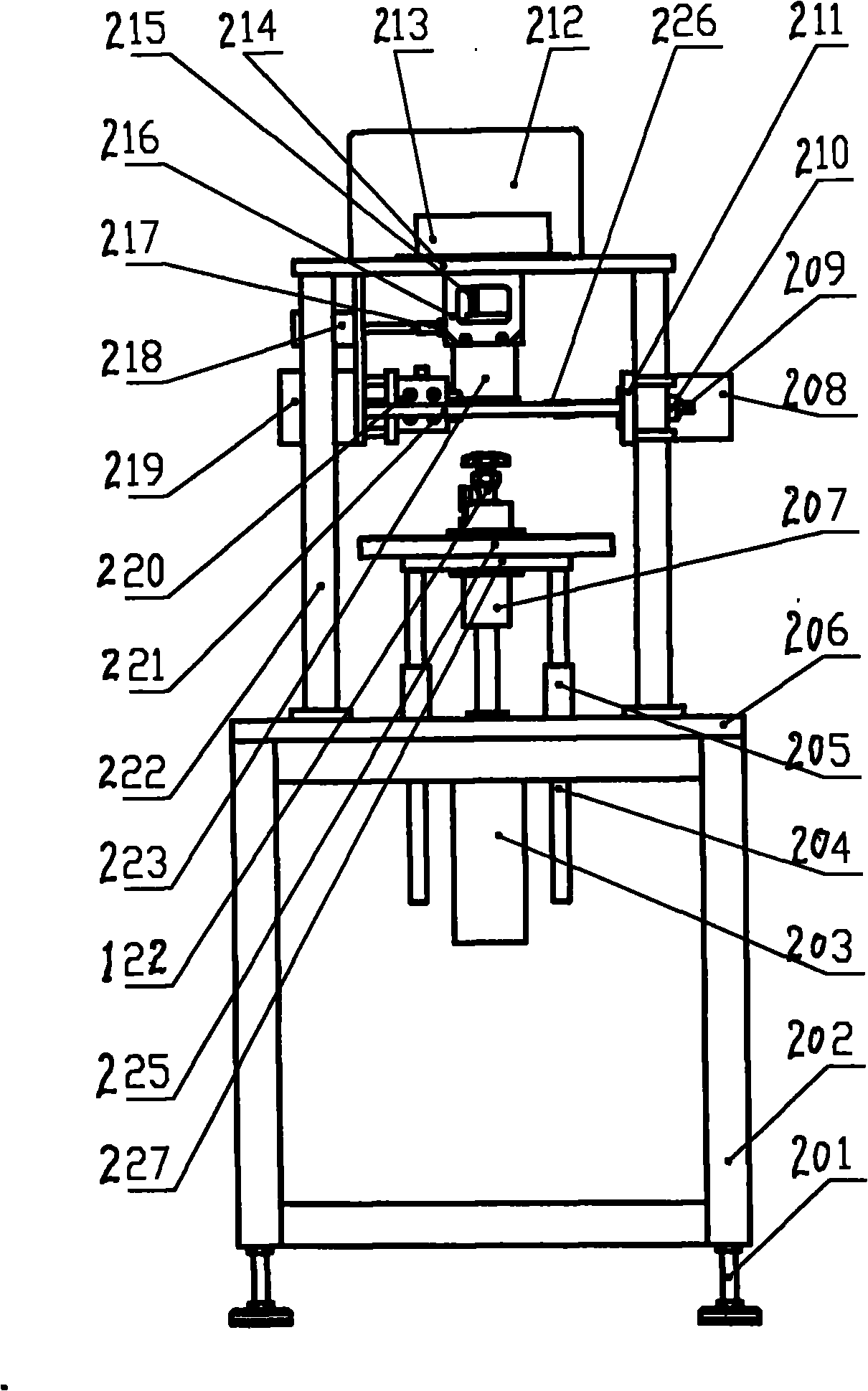

[0044] High-pressure closed and sealed test bench such as figure 1 , 2 As shown, 101 is an adjustable foot, 102 is a frame, 103 is a lifting cylinder, 104 is a guide shaft A, 105 is a table panel, 106 is a linear bearing A, 107 is a one-way valve, 108 is a back force cylinder, 109 110 is the linear bearing B, 111 is the back force cylinder mounting plate, 112 is the air circuit board, 113 is the axial flow fan, 114 is the top plate, 115 is the spring assembly, 116 is the sensor fixing plate, 117 is the sensor conversion cylinder, 118 is a blocking cylinder, 119 is a blocking block, 120 is a support column, 121 is a back force plate, 122 is a tested piece, 123 is a pallet, and 124 is a lifting plate.

[0045] According to the function, the detection equipment can be divided into main frame, lifting mechanism, side sealing degree mechanism, back force mechanism, sensor conversion mechanism and exhaust mechanism.

[0046] The main frame is composed of adjustable feet 101 , fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com