Automatic assembling line of liquefied petroleum gas cylinder valve

A technology of petroleum gas cylinders and assembly lines, which is applied to assembly machines, metal processing equipment, manufacturing tools, etc., and can solve problems such as cost increase, reliability impact, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] The present invention will be further described below in conjunction with accompanying drawing:

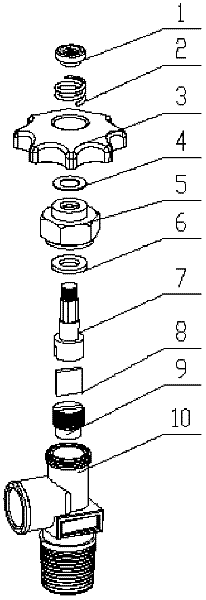

[0080] Such as figure 1 As shown, 1 is a round nut, 2 is a spring, 3 is a hand wheel, 4 is a paper pad, 5 is a nut, 6 is a rubber pad, 7 is a valve stem, 8 is a connecting piece, 9 is a valve core, and 10 is a valve body .

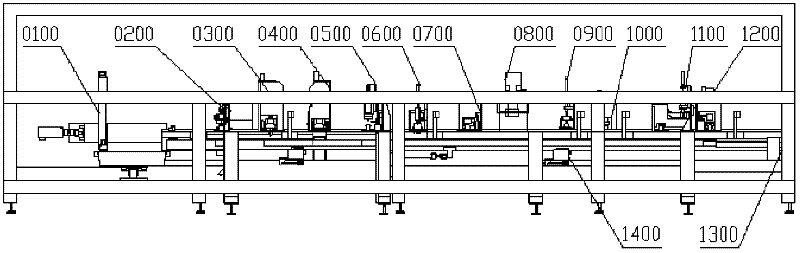

[0081] Such as figure 2 As shown, 0100 is the valve body loading workbench, 0200 is the valve core assembly workbench, 0300 is the connecting piece assembly workbench, 0400 is the valve stem assembly workbench, 0500 is the rubber pad assembly workbench, and 0600 is the oiling workbench , 0700 is the nut assembly workbench, 0800 is the nut tightening workbench, 0900 is the paper pad assembly workbench, 1000 is the hand wheel assembly workbench, 1100 is the spring assembly workbench, 1200 is the round nut assembly workbench, 1300 is the finished product drop Material workbench, 1400 is a line body.

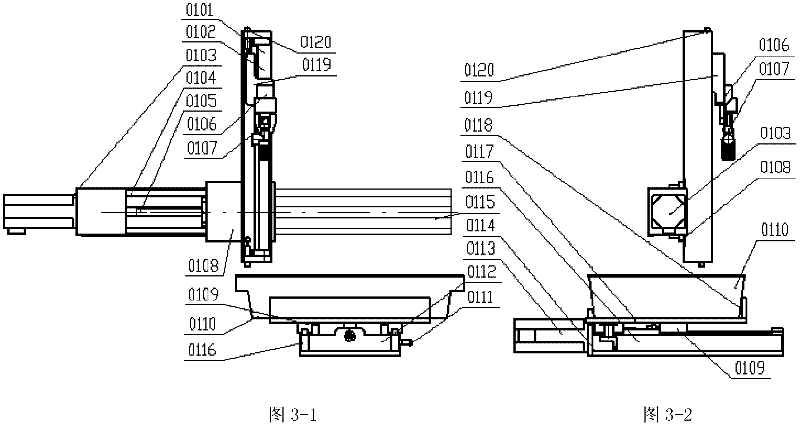

[0082] Such as Figure 3-1 , 3-2 As shown, 0101 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com