Obstructing pulling method pile digging construction device and method

The technology of a construction device and construction method, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of low efficiency, high operation intensity, and high cost, and achieve the effects of reducing strength, reducing labor intensity, and reducing noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

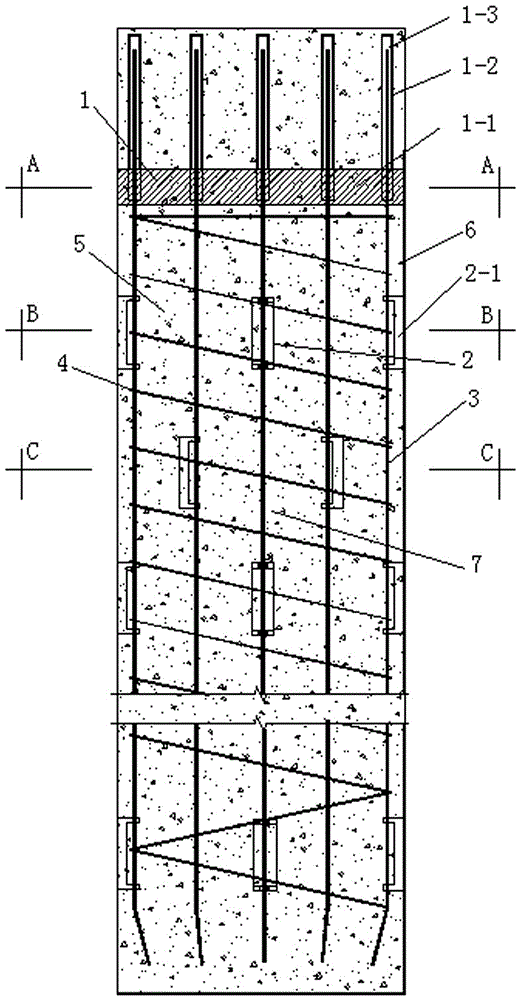

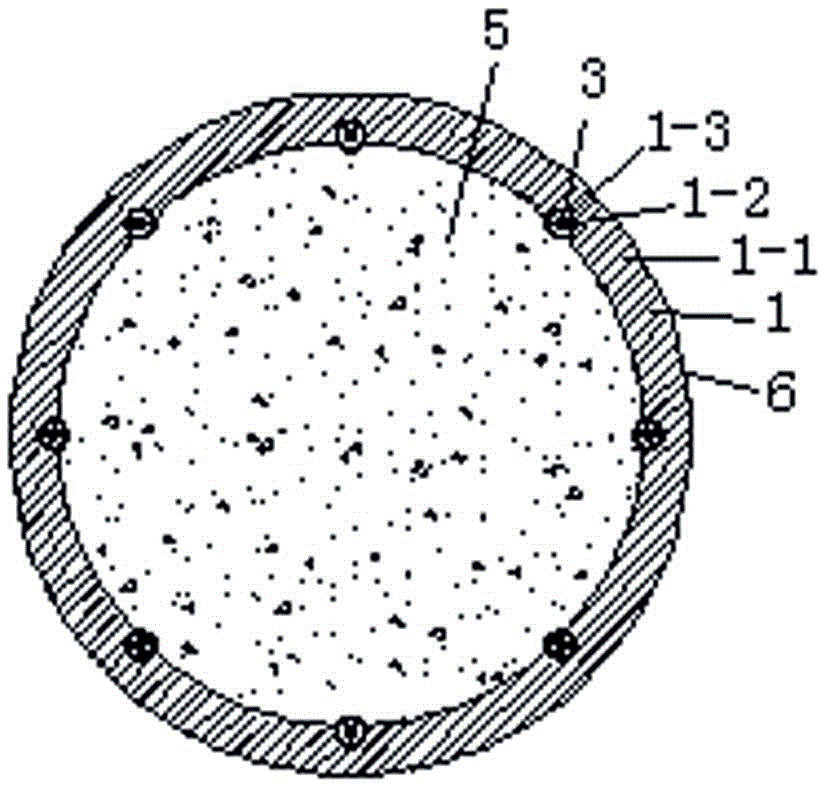

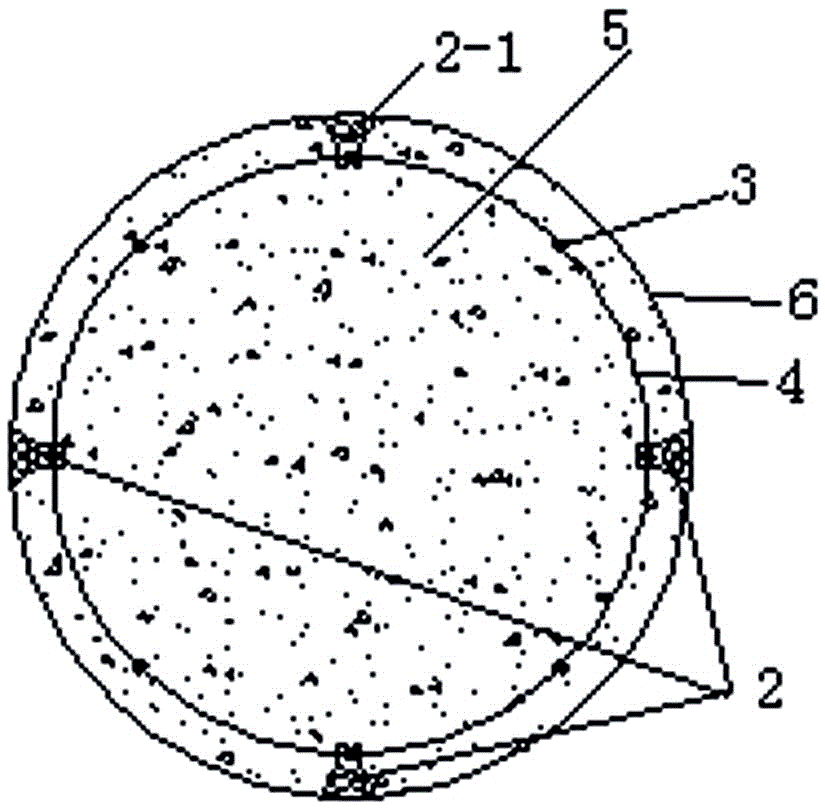

[0033] The present invention will be described in detail below in conjunction with accompanying drawing: Figures 1 to 4 As shown, the present invention includes the main bars 3 of the steel cage and the stirrups 4 of the steel cage. The main bars 3 of the steel cage are distributed in an equal and surrounding manner, and the steel cage 7 is formed by winding and fixing the stirrups 4 of the steel cage in a spiral manner sequentially. Described reinforcing cage 7 is placed in bored cast-in-situ pile forming hole 6, and described reinforcing cage 7 is provided with reinforcing cage protection layer device 2, and the top of reinforcing cage 7 is provided with concrete pre-separation device 1; Described reinforcing bar The cage protective layer device 2 is arranged every 3m along the length direction of the steel cage 7, and each steel cage protective layer device 2 is provided with a protective layer 2-1 every 90 degrees along the circumference, and the adjacent upper and lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com