Stapler convenient for stapling

A stapler and convenient technology, applied in the direction of bookbinding, can solve the problems of increasing labor intensity of workers, affecting the quality of bookbinding, and high labor intensity of workers, so as to improve the quality and aesthetics of bookbinding, improve the efficiency of installation, and realize bookbinding. automated effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and examples, but not as a basis for limiting the present invention.

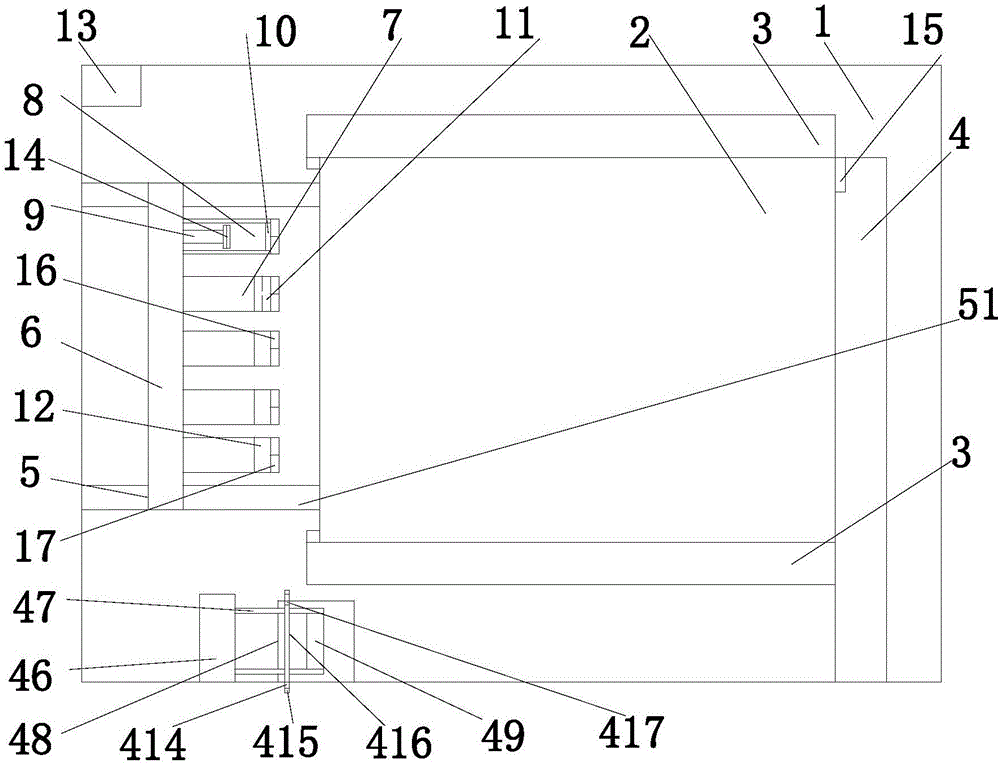

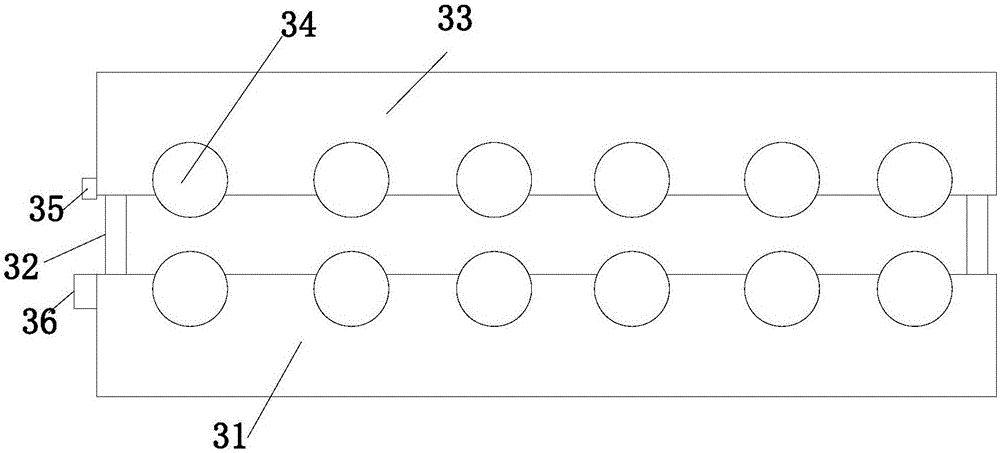

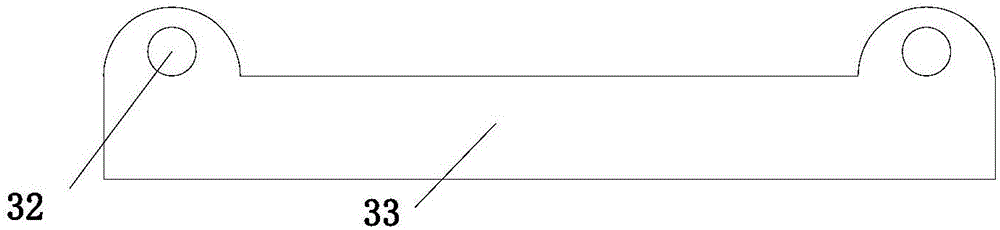

[0023] Example. A stapler for easy binding, constituted as Figure 1 to Figure 9 As shown, it includes a base 1, a binding platform 2 is arranged on the base 1, an input track 3 is provided at both ends of the binding platform 2, an output track 4 is provided on one side of the binding platform 2, and a binding device is provided on the other side of the binding platform 2 , the binding device includes a bracket 5 of a hydraulic telescopic structure, the upper end of the bracket 5 is provided with a sliding track 6, and a group of nail pressing assemblies are arranged on the sliding rail 6, and the nail pressing assembly includes a needle storage part 7, and a needle storage groove is arranged in the needle storage part 7 8. There is a hydraulic push rod 9 inside the needle storage tank 8, a needle ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com