Automatic control device and control method for loose package detection of cigarette box transparent wrapping paper

An automatic control device and transparent packaging technology, applied in the direction of packaging cigarettes, cigars, etc., can solve the problems of missing detection of loose cigarette packets and effective rejection, inability to effectively ensure the full efficiency of equipment operation, and loose transparent paper on cigarette packaging and packaging. Achieve the effect of improving the detection speed and accuracy, reducing the labor intensity of workers, and working stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

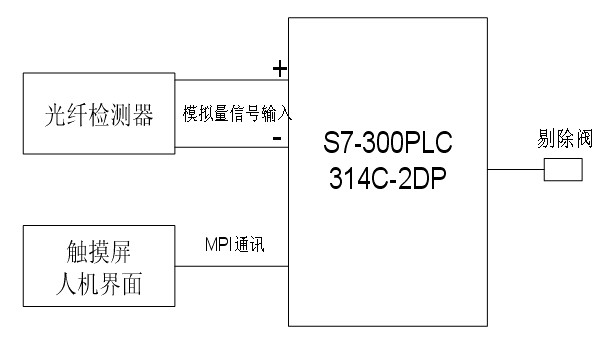

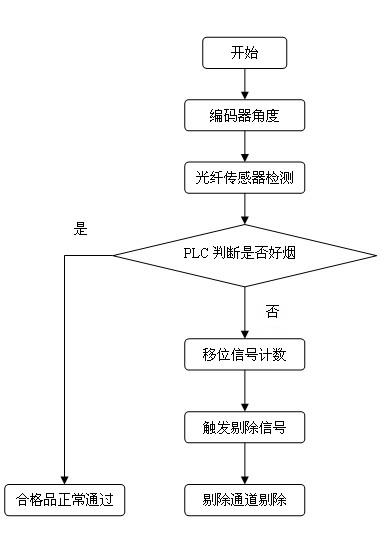

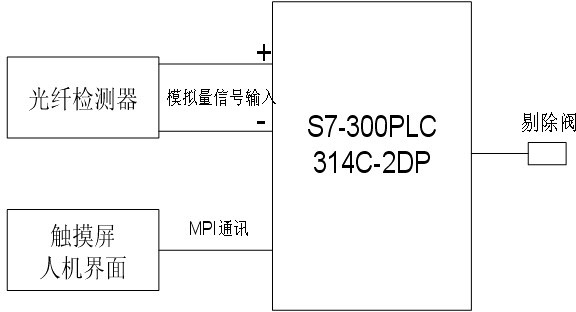

[0017] see figure 1 , an automatic control device for detection of loose packs of transparent wrapping paper for cigarette boxes, comprising an optical fiber detector composed of an optical fiber probe and an optical fiber amplifier, and a programmable logic controller PLC with a cigarette case packaging unit, characterized in that: the optical fiber detector The optical fiber probe is installed and fixed at the exit of the cigarette pack turret of the cigarette case packaging unit through the fixing bracket, and the optical fiber amplifier of the optical fiber detector is installed and fixed on the main wallboard of the cigarette case packaging unit. The programmable logic controller PLC in the remote terminal of the unit is connected, and a packet detection function module is set in the programmable logic controller PLC. The programmable logic controller PLC is connected to the touch screen through the MPI communication input port. A rejection valve is connected to the outpu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com