Automatic powder control subpackaging device and method

An automatic, sub-packaging technology, applied in the directions of packaging, solid materials, transportation and packaging, to achieve the effect of reducing the cost of aseptic processing, reducing manual participation, and reducing sterility requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

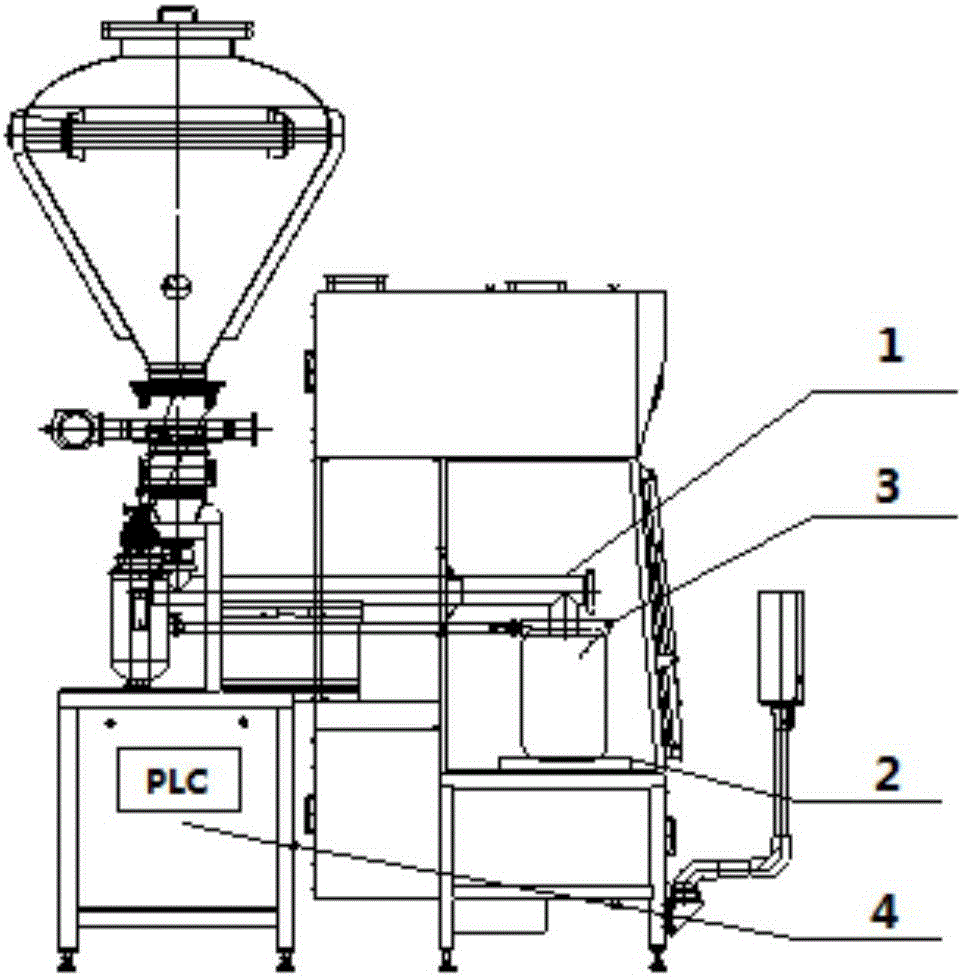

[0026] Such as figure 1 As shown, the embodiment of the present invention provides a control powder automatic packaging device, including: feeding equipment 1, weighing equipment 2, storage equipment 3 and control equipment 4, weighing equipment 2 is used for weighing storage The tare weight of equipment 3 and the real-time net weight of materials, the material inlet of storage equipment 3 is connected to the outlet of feeding equipment 1, the weighing equipment 2 is connected to the communication port of control equipment 4, and the output terminal of control equipment 4 Data connection to the speed control unit of the feeding device 1.

[0027] The automatic dispensing device of above-mentioned structure, its work process is:

[0028] The material enters the feeding equipment from the temporary storage silo, and enters the storage equipment through the feeding equipment. During the above-mentioned feeding and packaging process, the weighing equipment can know the real-time ...

Embodiment 2

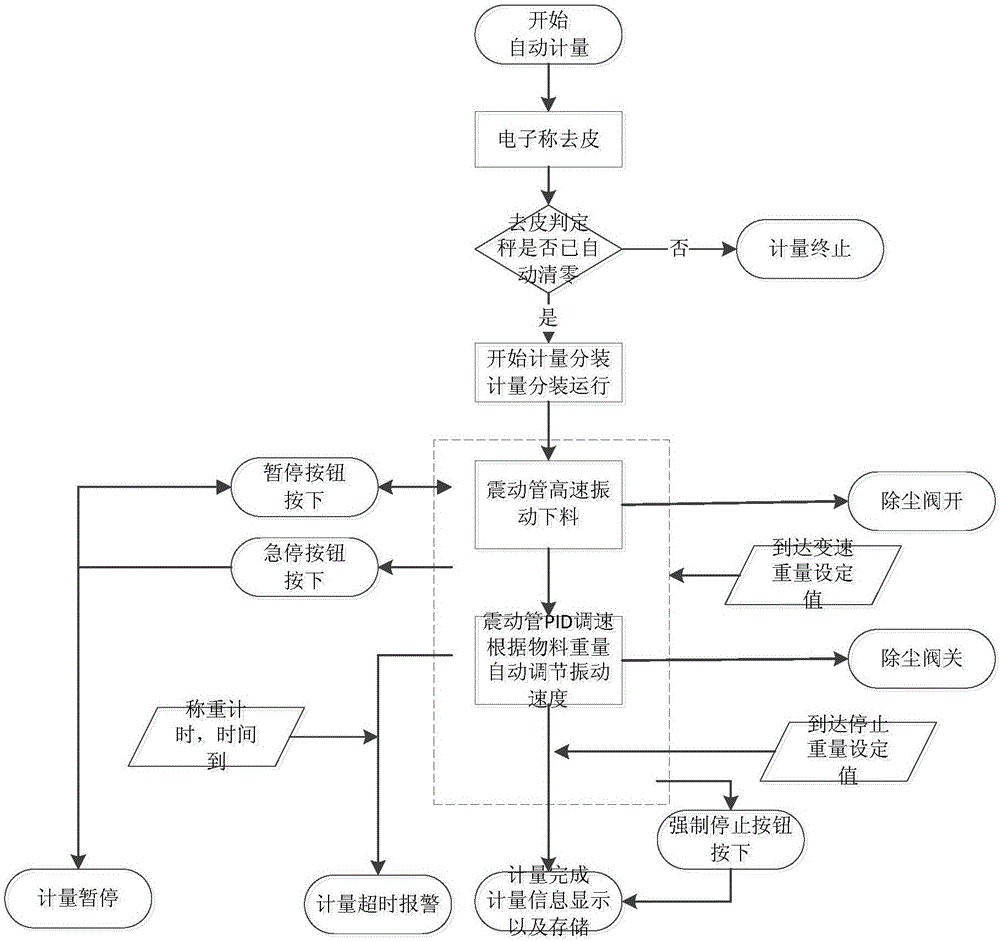

[0036] Such as figure 2 As shown, the embodiment of the present invention provides a method for controlling powder automatic dispensing, adopting the control powder automatic dispensing device described in Embodiment 1, including the following steps:

[0037] S1, setting switching weight, first feeding speed and second feeding speed, the first feeding speed is greater than the second feeding speed;

[0038] S2, the weighing equipment is reset, and the weight of the storage equipment is weighed;

[0039] S3, start the feeding equipment, and start feeding according to the first feeding speed;

[0040] S4, judging whether the weight of the storage device reaches the set switching weight, if so, feeding according to the second feeding speed, otherwise, feeding according to the first feeding speed.

[0041] Using the above method, the feeding speed is controlled according to the weight of the feeding material. When the feeding starts, a higher feeding speed is used, and when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com