High-precision low-damage automatic filling machine

An automatic filling and low-damage technology, applied in the field of mechanical structure, can solve the problems of lack of sub-packaging device, insufficient accuracy, large size of equipment, etc., and achieve the effect of less material processing damage, convenient operation and high sub-packaging accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

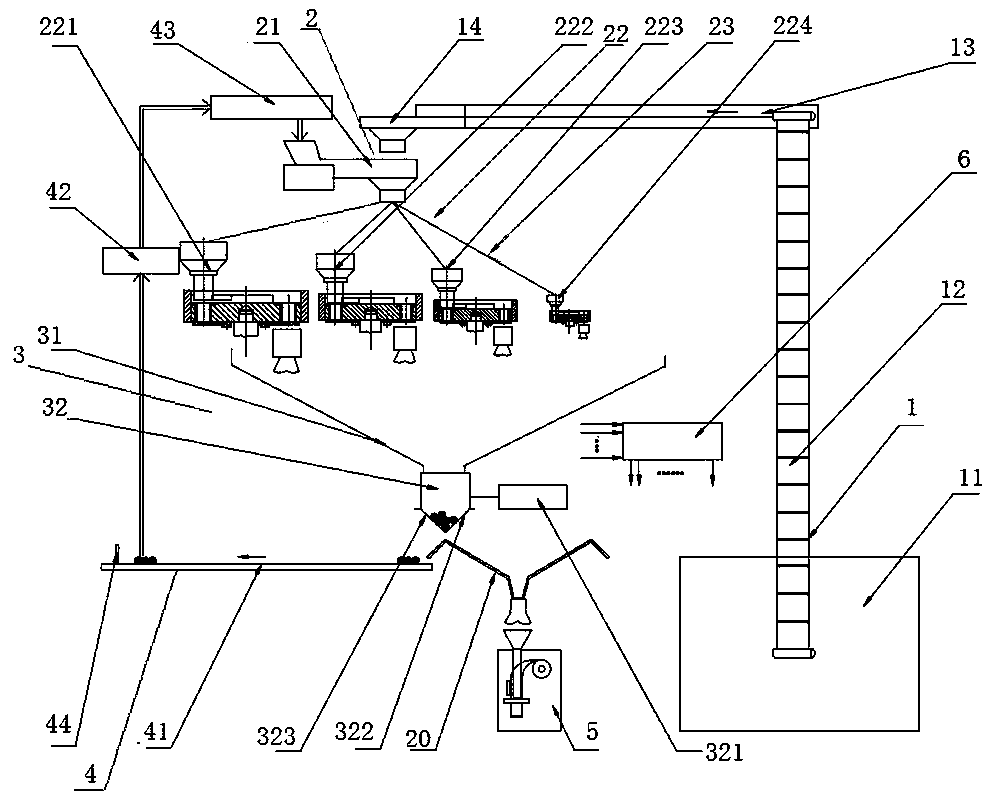

[0023] Such as figure 1 Shown is an embodiment of a high-precision and low-damage automatic filling machine of the present invention. The automatic filling machine includes a feeding module 1, a feeding module 2, a detection module 3 for detecting whether the material is qualified, and a recovery of unqualified materials. The recycling module 4 and the packaging module 5 for packaging qualified materials, the automatic filling machine also includes a controller 6 for controlling the entire working process of the automatic filling machine.

[0024] Wherein, the feeding module 1 includes a hopper 11 , a hoist 12 , a conveyor belt 13 , and a discharge hopper 14 connected in sequence. This setting is to enable the materials to be transported up smoothly, so as to facilitate the smooth progress of the subsequent material distribution module.

[0025] In addition, the hoist 12 is a vertical flexible hoist, and the hoist 12 is provided with several lifting plates isolated by rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com