Intelligent recycling device for cement paste

A kind of cement slurry and intelligent technology, which is applied in the field of cement slurry intelligent recycling device, can solve the problems of irregular cleaning, untimely utilization, easy to block equipment, etc., and achieve the effect of being easy to be widely used, reasonable in structural design, and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

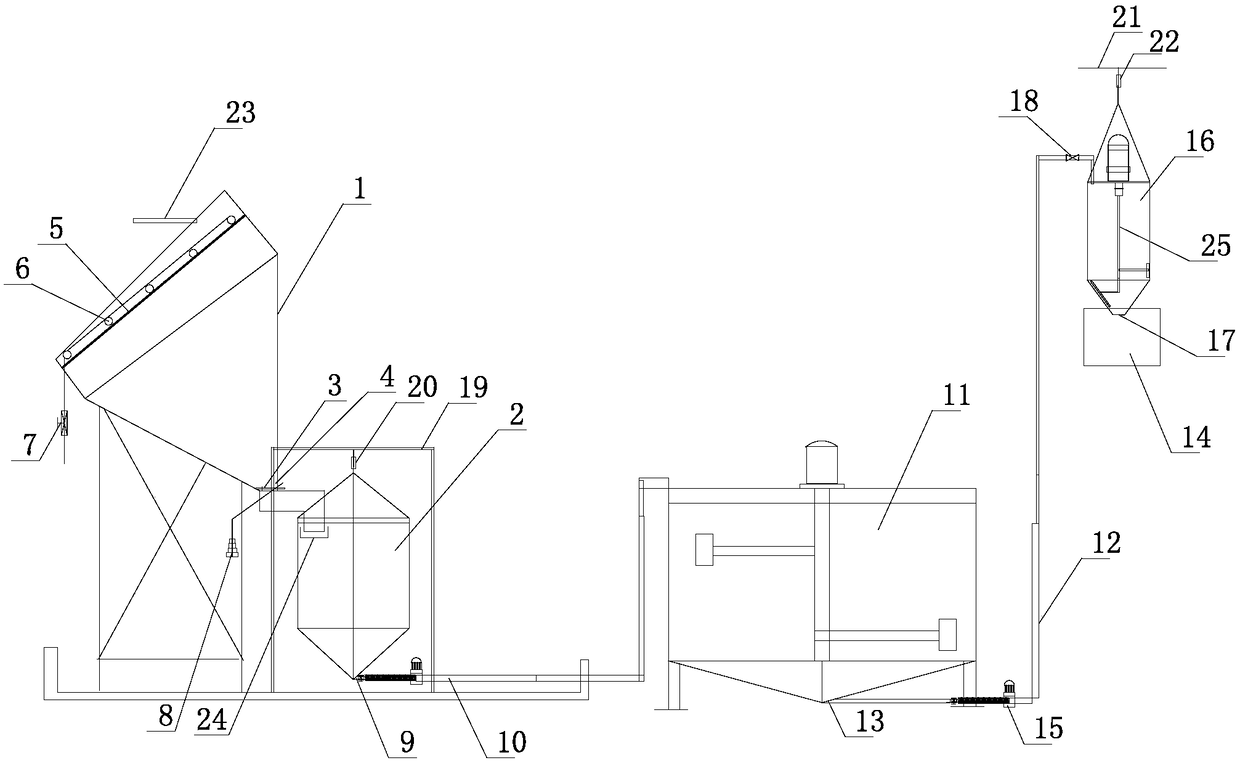

[0019] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0020] like figure 1 As shown in , a cement slurry intelligent recycling device includes a slurry pouring hopper 1, the bottom of the slurry pouring hopper is provided with a first discharge port 4, and the first feed port of a water distribution cement slurry scale hopper 2 is hinged on the The weight flap 3 inside the first discharge port is connected with the first discharge port 4; a screen 5 is arranged in the upper opening of the pouring hopper 1, and the pouring hopper 1 on the upper side of the screen 5 An annular water spray pipe 6 is arranged on the inner wall of the upper opening, and the annular water spray pipe 6 is connected with a water inlet pipe through a water inlet pneumatic butterfly valve 7, and the weight flap 3 is connected with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com