A water distribution system with automatic identification function

A water distribution system and automatic identification technology, applied in mixer accessories, mixers, dissolving and other directions, can solve the problems of troublesome process of adding water and affect work efficiency, and achieve the effect of reducing workload and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

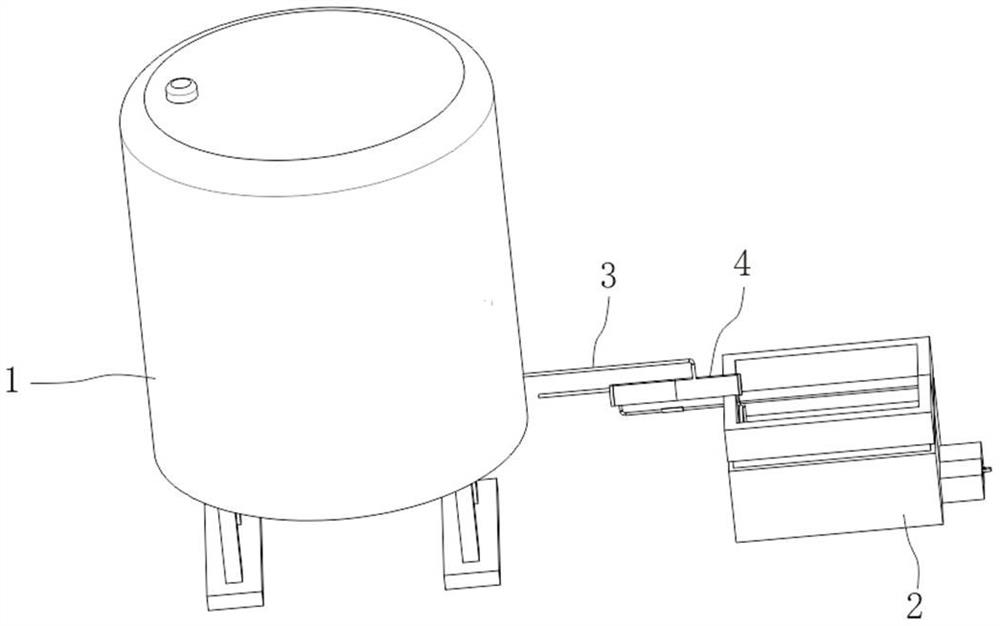

[0037] The invention provides a technical solution: a water distribution system with automatic identification function, please refer to figure 1 , including: a water storage tank 1 and a mixing tank 2;

[0038] A water pump is installed at the bottom of the inner cavity of the water storage tank 1, and the outlet of the water pump is connected to the conduit 3. The top wall of the mixing tank 2 is equipped with a water distribution mechanism 4, and the end of the conduit 3 away from the water pump is connected to the water distribution mechanism 4. The electrical equipment involved in the device Both are electrically connected by wires and external power switches;

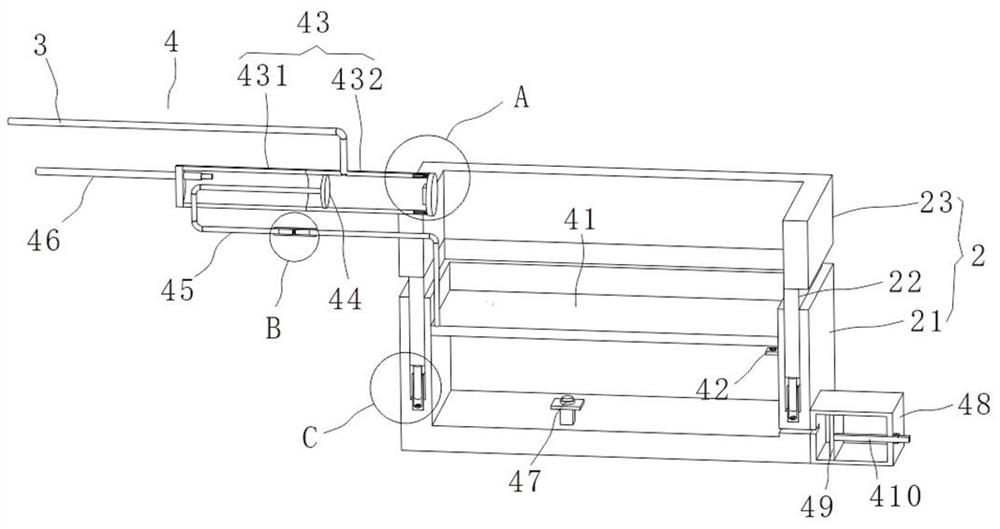

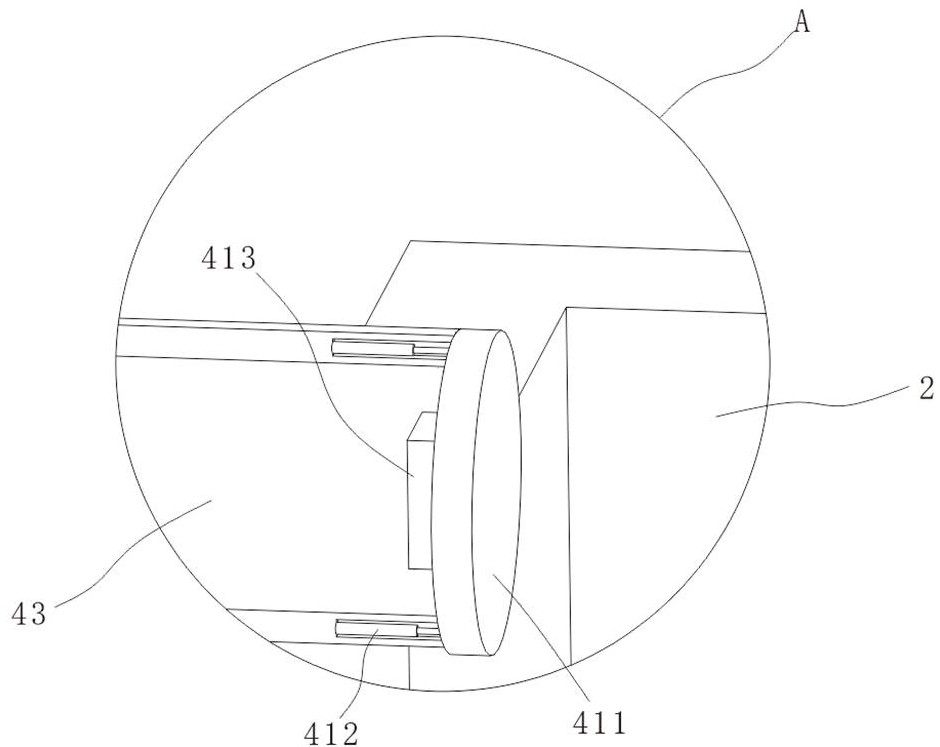

[0039] see figure 2 , the water distribution mechanism 4 includes a supporting plate 41 slidably installed in the inner cavity of the mixing tank 2, the bottom wall of the supporting plate 41 and the bottom of the inner cavity of the mixing tank 2 are filled with air, and the inner wall on the right side of the m...

Embodiment 2

[0046] see figure 2 and Figure 5 , on the basis of Embodiment 1, the mixing pool 2 includes an upper pool body 23 and a lower pool body 21, the top wall of the lower pool body 21 is provided with a mounting groove, and the bottom wall of the upper pool body 23 is equipped with a movable block 22, and the movable block 22 slides into the In the inner cavity of the installation groove, and the bottom of the inner cavity of the installation groove is equipped with an installation sleeve 5, the top of the installation sleeve 5 inner cavity is slidingly inserted with a push rod 6, the top of the push rod 6 is connected with the bottom wall of the movable block 22, and the push rod 6 A magnetic block is installed at the bottom, an electromagnet 7 is installed at the bottom of the inner cavity of the installation sleeve 5, and a push switch 47 is installed at the bottom of the inner cavity of the lower pool body 21, and the push switch 47 is electrically connected with the electrom...

Embodiment 3

[0050] In order to enhance the practicability of the equipment of this application, expand its functions, and enhance the mixing efficiency of water and raw materials, the embodiment of this application adds an auxiliary mixing component 8 on the basis of the above-mentioned embodiments, and uses gas to accelerate the mixing process by accumulating and releasing elastic potential energy. The mixing of raw materials and water on the supporting plate 41; specifically:

[0051] Such as Figure 6 to Figure 16 As shown, the auxiliary mixing assembly 8 includes an air storage air bag assembly 81 and an air injection restriction assembly 82; the air storage air bag assembly 81 is located under the support plate 41, and its main body is an air bag structure for storing gas; The air injection restriction assembly 82 is used to limit the output of the gas in the air storage airbag assembly 81, and acts as a valve body; in actual use, the air storage airbag assembly 81 injects air into t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com