Industrial explosive carton automatic car loading system

An industrial explosive and automatic loading and unloading technology, which is applied in the directions of transportation and packaging, loading/unloading, object stacking, etc., can solve the problems of high labor intensity, many online personnel, and the inability to realize unmanned, so as to improve the degree of intelligence Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

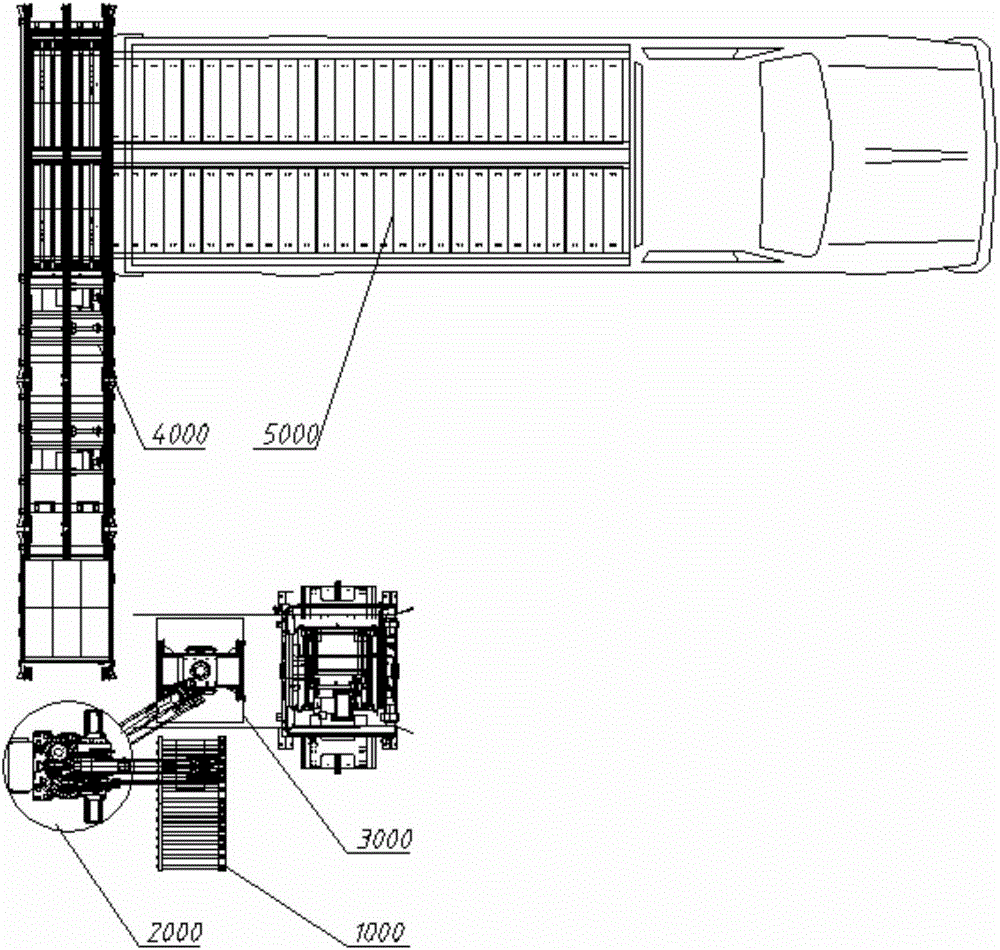

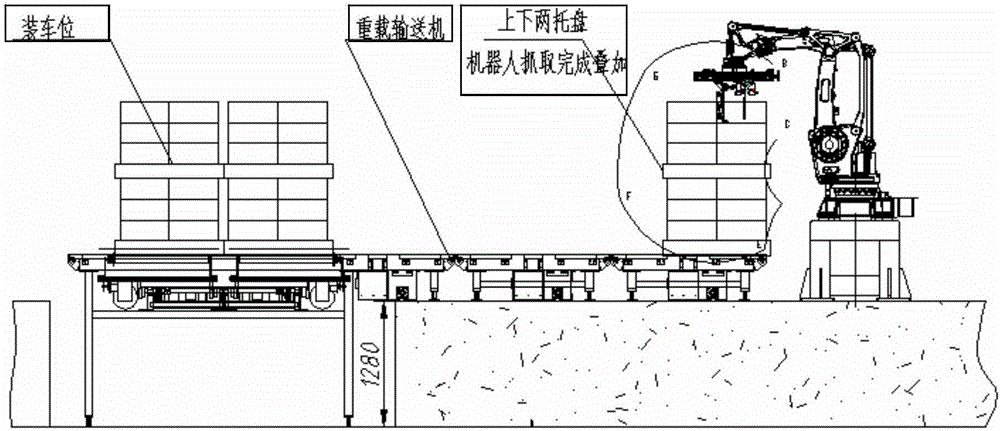

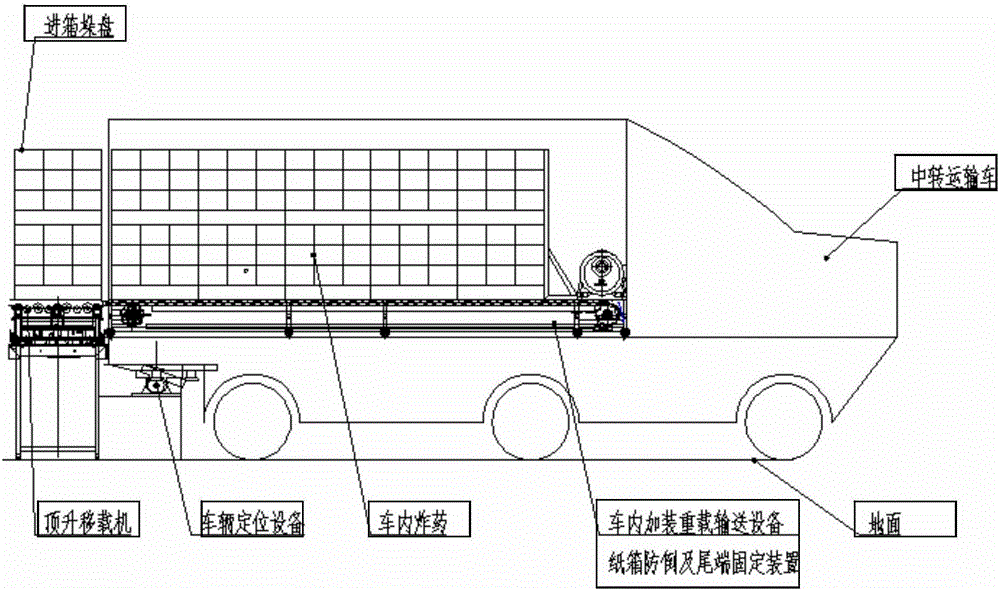

[0034] Such as figure 1 , figure 2 , image 3 As shown, the automatic loading system for industrial explosive cartons is mainly composed of carton conveying equipment 1000, carton palletizing equipment 2000, light-load pallet conveying equipment 3000, heavy-duty pallet conveying equipment 4000, transfer platform automatic loading and unloading equipment 5000 and electronic control parts; The part controls the coordinated actions of the whole system and jointly completes the corresponding functions. Carton conveying equipment 1000, carton palletizing equipment 2000, light-load pallet conveying equipment 3000, heavy-duty pallet conveying equipment 4000, and transfer platform automatic loading and unloading equipment 5000 are respectively fixed on the ground. And the carton palletizing equipment 2000 is respectively connected with the carton conveying equipment 1000 and the light-load pallet conveying equipment 3000, the output end of the light-load pallet conveying equipment 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com