Temperature tester based on film type temperature sensor and its manufacture method

A technology of temperature sensor and manufacturing method, applied in thermometer parts, thermometers and thermometers with directly sensitive electrical/magnetic elements, etc., can solve the problem of high production cost, weak mechanical shock or vibration strength, and loss of competitiveness and other problems, to achieve the effect of firm structure and increased filling density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

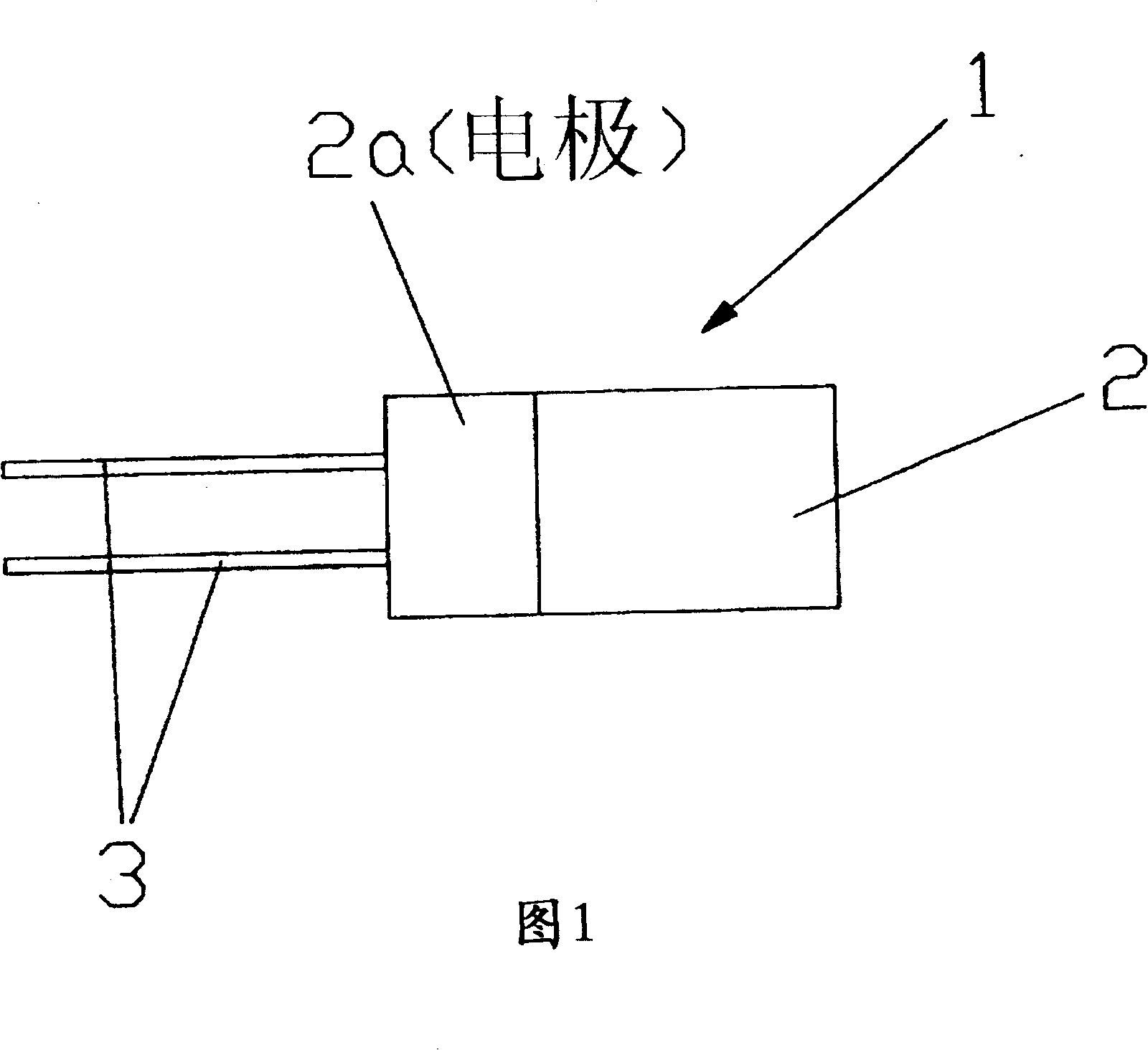

[0041] The temperature tester based on the thin film temperature sensor of the present invention and its manufacturing method are described below with reference to the accompanying drawings.

[0042] Image 6and Figure 7 This is a diagram of the soldering process between the sensor pins of the thin-film temperature sensor and the metal leads for external output.

[0043] Image 6 The platinum thin film temperature sensor 100 is shown in the process of bonding the thin film sensor pin 112 of the thin film temperature sensor body 110 and the metal lead 212 to the welding portion (overlapping portion) by melting silver Ag (also called a silver spot). Ag spotwelding) (forming silver spot welding 300); Figure 7 It is shown that the platinum thin film temperature sensor 100-1 is welded (overlapped) between the thin film sensor pin 112 and the metal lead 212 of the thin film temperature sensor body 110 by an arc (Arc) method without using an intermediate medium. A process in wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com