A method for producing a hybrid magnet and the hybrid magnet produced by the method

A technology of magnets and mixtures, applied in the direction of magnetic circuits characterized by magnetic materials, magnetic objects, inductors/transformers/magnets, etc., can solve the problem of limited mechanical strength and thermal durability, and the magnetism that is not fully utilized. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

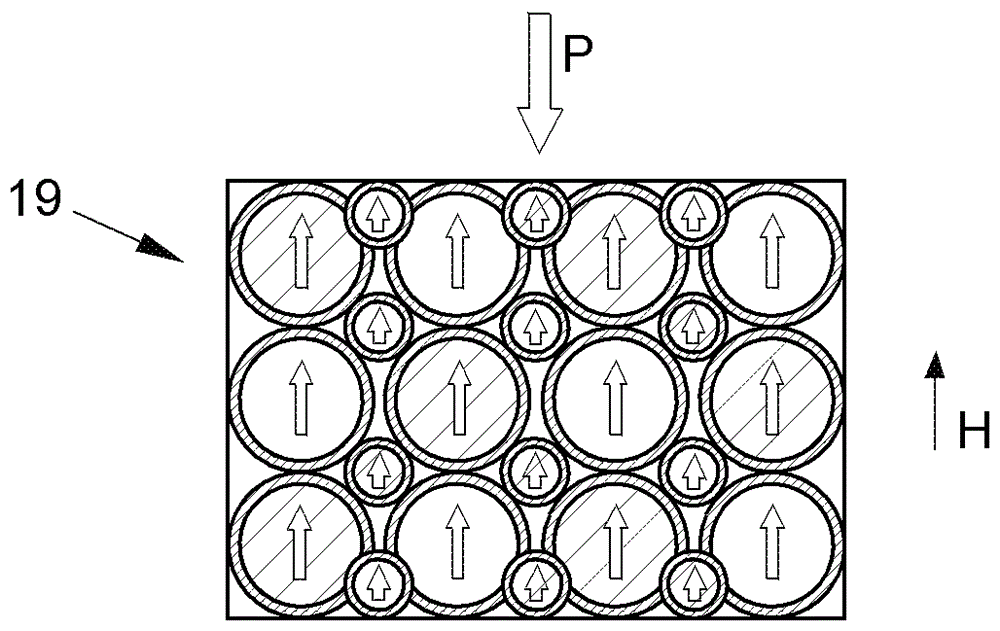

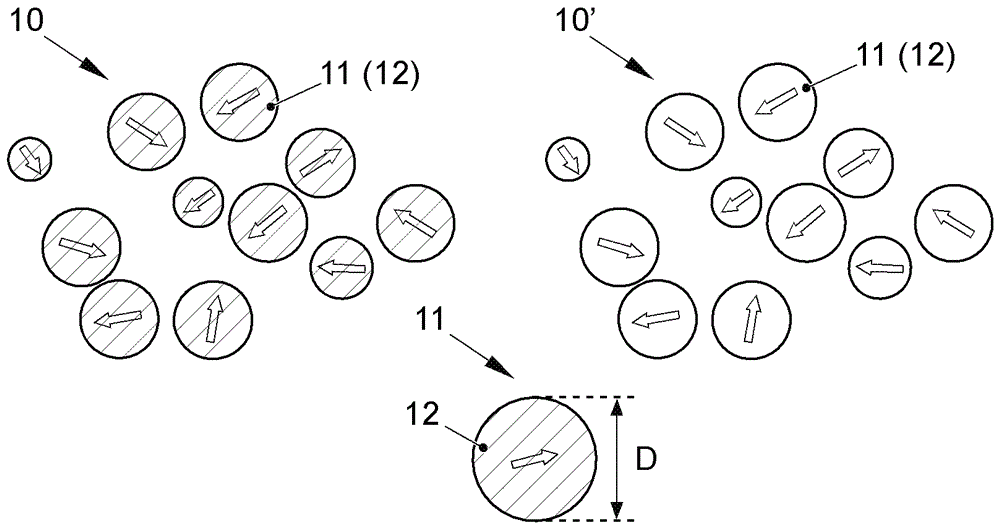

[0086] figure 1 A flow diagram of the method according to the invention according to a first embodiment is shown. The very schematic intermediate products and end products of the different process steps are shown in FIG. 2 .

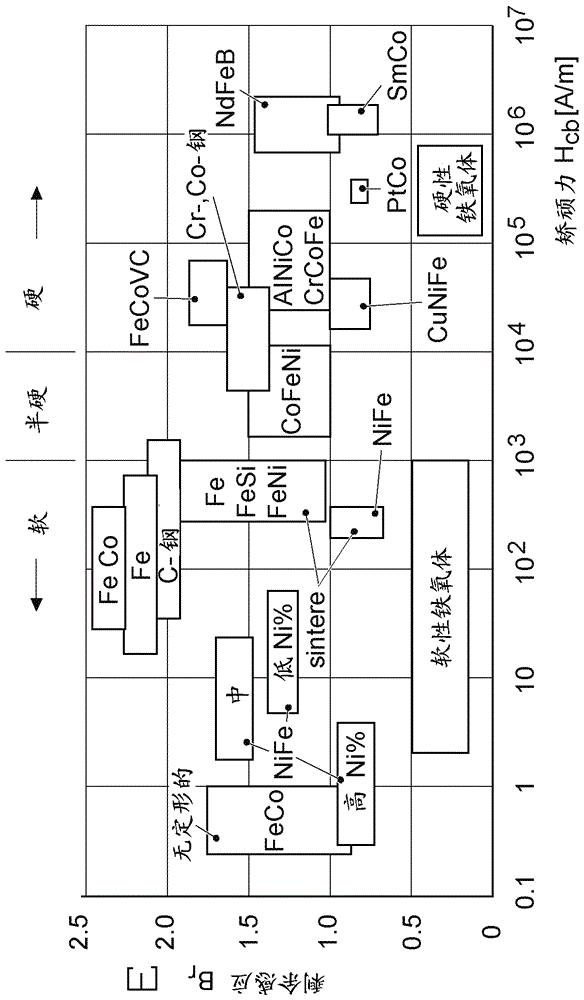

[0087] Firstly, in step S1 a first powder 10 of a first magnetic material 12 (hereinafter also referred to as magnetic material or magnetic raw material) is provided. For example, a hard magnetic material such as an alloy of the composition Nd2Fe14B is used as the first magnetic material 12 . The starting point for the powdering is, for example, magnetic raw materials, which are melted in a vacuum induction furnace, poured out and solidified by cooling. Here, the crystalline structure will give an isotropic alloy. After hardening, the product, for example in the form of strips, can be broken mechanically and subsequently ground, for example in a jet mill, under an inert gas atmosphere (eg nitrogen). Other methods of powder production can likewise be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com