Vehicle cockpit with self supporting submodules

一种机动车、子模块的技术,应用在车辆部件、上部结构分总成、仪表板等方向,能够解决繁琐安装过程、大时间间隔等问题,达到缩短时间间隔、改善可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

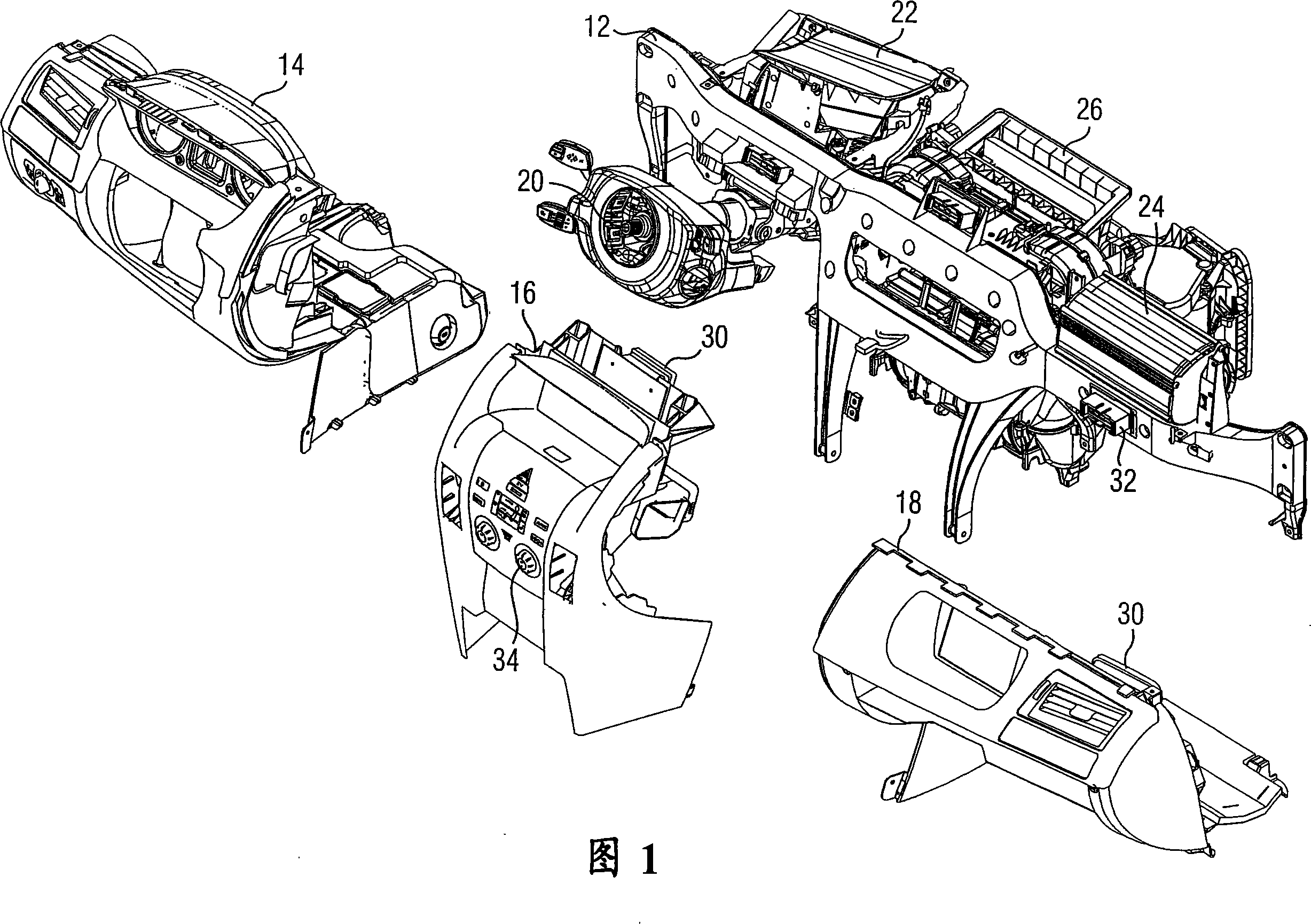

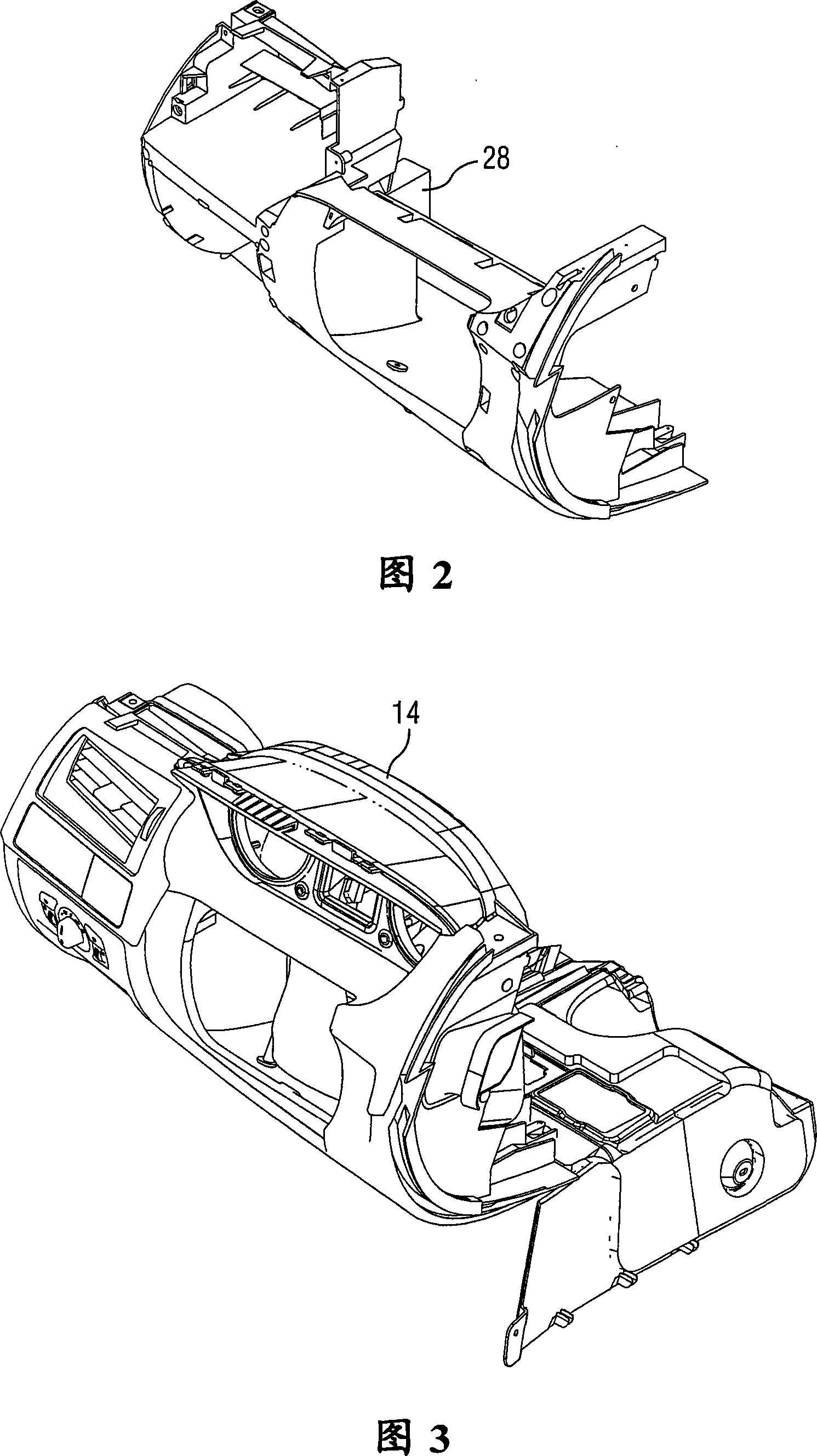

[0020] 1 shows a motor vehicle cockpit (dashboard module assembly (cockpit)), the motor vehicle cockpit has a cross member 12 extending with the width of the cockpit, a driver submodule 14, a center console submodule 16 and Copilot sub-module 18. A cover (not shown) is mounted as an upper closure to the vehicle cabin. Various assemblies and components, such as steering column 20 , head-up display 22 , airbags 24 and heating system 26 , are fastened directly to cross member 12 , which also serves to transmit lateral forces in the event of a side impact. The submodules 14, 16, 18 are self-supporting so as to be freely maneuverable as preassembled components. In the installed state, the submodules 14 , 16 , 18 transmit their own weight and external loads to the cross member 12 . At the same time, only the connection means for carrying are provided between the submodules 14 , 16 , 18 and the crossbeam 12 .

[0021] The submodules 14 , 16 , 18 have a plastic frame as the base st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com