Method for treating phenol-containing wastewater with polyelectrolyte-surfactant

A technology of surfactants and polyelectrolytes, applied in water/sewage treatment, chemical instruments and methods, extraction water/sewage treatment, etc., can solve problems such as incomplete degradation, easy saturation of adsorbents, and difficult control of intermediate products, and achieve Good adsorption solubilization effect, good emulsification, easy synthesis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method utilizing polyelectrolyte-surfactant to process phenol-containing wastewater, comprising the following steps:

[0026] Add polysodium methacrylate (PMAA) 0.03g and cetyltrimethylammonium bromide (CTAB) 0.45×10 per liter of phenol-containing wastewater -3 mol, polysodium methacrylate (PMAA) and cetyltrimethylammonium bromide (CTAB) were added to phenol-containing wastewater with a concentration of 100 mg / L at the same time, stirred at a speed of 250 r / min for 1 min, and statically After standing for 1.0h, CTAB monomer molecules and PMAA self-assembled to form aggregates with adsorption and solubilization of phenol molecules during the standing process. Filtration treatment, wherein the ultrafiltration membrane module is a hollow fiber ultrafiltration membrane module, the material of the ultrafiltration membrane is polysulfone, the molecular weight cut off of the membrane is 10000Dalton, the operating pressure of the membrane is 0.03Mpa, and the operation mode of...

Embodiment 2

[0030] A method utilizing polyelectrolyte-surfactant to process phenol-containing wastewater, comprising the following steps:

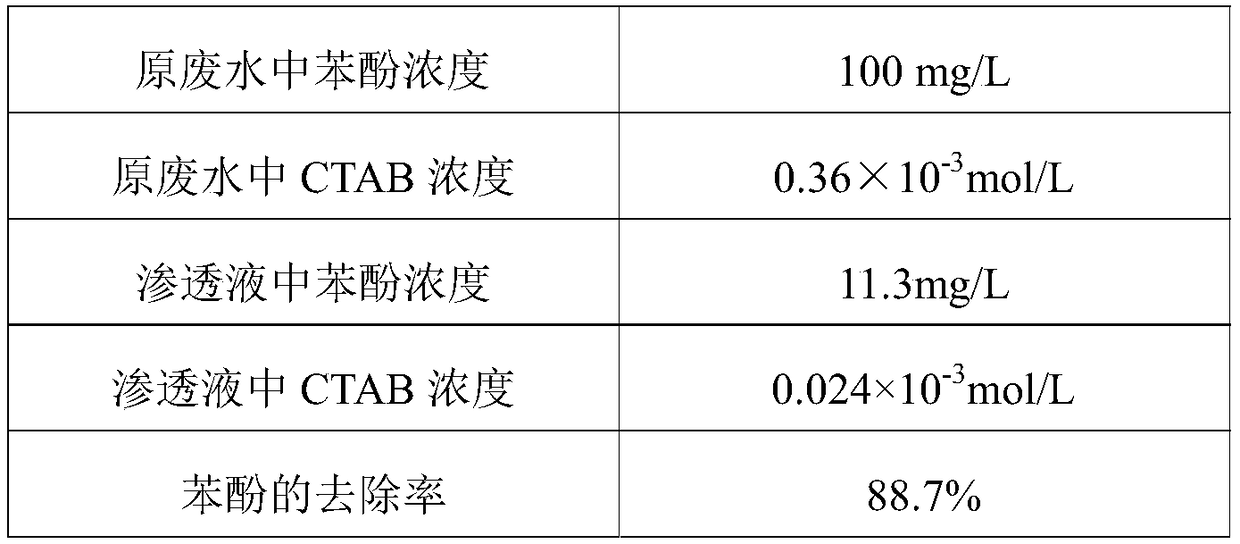

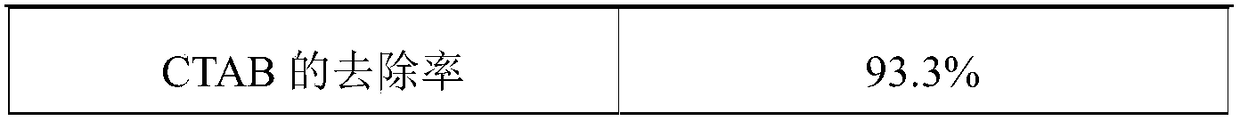

[0031] Add polysodium methacrylate (PMAA) 0.03g and cetyltrimethylammonium bromide (CTAB) 0.36×10 per liter of phenol-containing wastewater -3 mol, polysodium methacrylate (PMAA) and cetyltrimethylammonium bromide (CTAB) were added to the phenol-containing wastewater with a concentration of 100mg / L at the same time, stirred at a speed of 200r / min for 2min, and statically After standing for 0.5h, CTAB monomer molecules and PMAA self-assembled to form aggregates with adsorption and solubilization of phenol molecules during the standing process. Filtration treatment, wherein the ultrafiltration membrane module is a hollow fiber ultrafiltration membrane module, the material of the ultrafiltration membrane is polysulfone, the molecular weight cut off of the membrane is 8000Dalton, the operating pressure of the membrane is 0.03Mpa, and the operation mode of...

Embodiment 3

[0036] A method utilizing polyelectrolyte-surfactant to process phenol-containing wastewater, comprising the following steps:

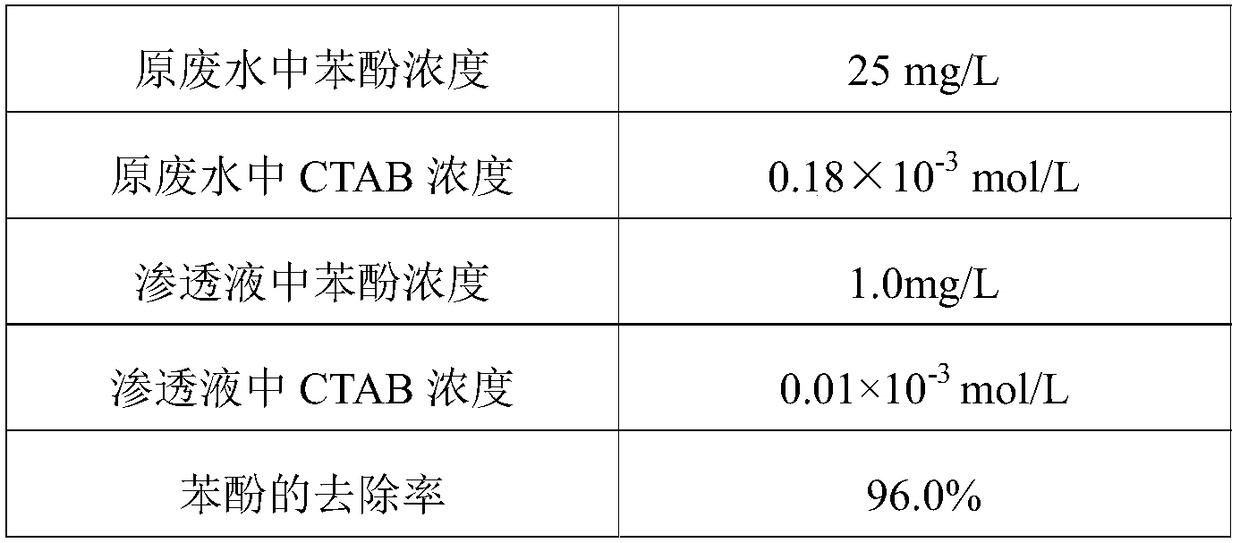

[0037] Add polysodium methacrylate (PMAA) 0.02g and cetyltrimethylammonium bromide (CTAB) 0.225×10 per liter of phenol-containing wastewater -3 mol, polysodium methacrylate (PMAA) and cetyltrimethylammonium bromide (CTAB) were added to the phenol-containing wastewater with a concentration of 50mg / L at the same time, stirred at a speed of 200r / min for 5min, and statically After standing for 0.5h, CTAB monomer molecules and PMAA self-assembled to form aggregates with adsorption and solubilization of phenol molecules during the standing process. Filtration treatment, wherein the ultrafiltration membrane module is a hollow fiber ultrafiltration membrane module, the material of the ultrafiltration membrane is polysulfone, the molecular weight cut off of the membrane is 10000Dalton, the operating pressure of the membrane is 0.03Mpa, and the operation mode o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com