Method for filling coal-steam-free extraction working surface goaf by coal mine waste rock

A technology for working face and goaf, which is applied in filling materials, ground mining, mining equipment, etc., can solve the problems of ineffective gangue filling, inability to support the roof, and high labor intensity of employees, so as to save land acquisition costs and improve the environment of coal mines. , the effect of filling a wide area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

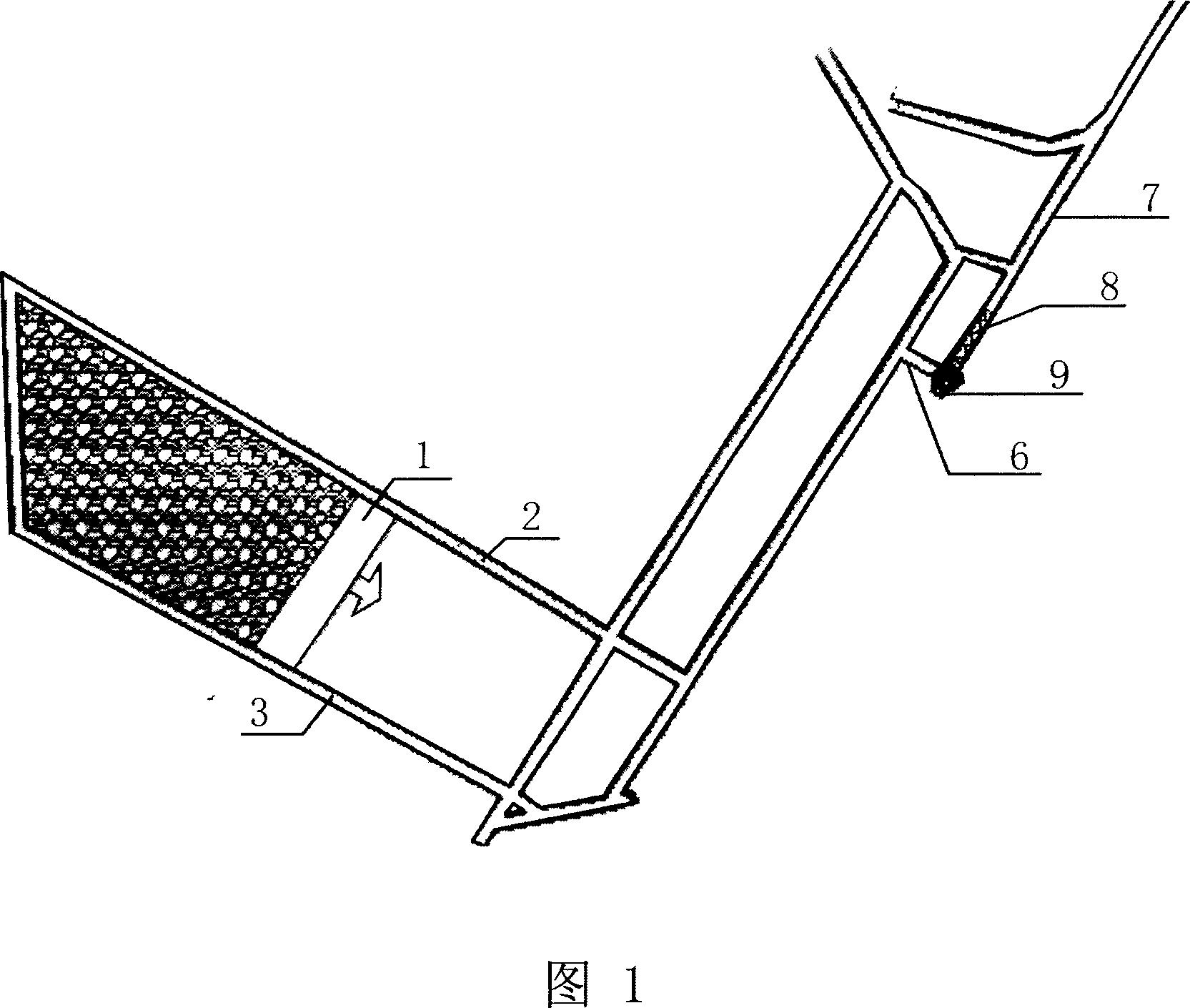

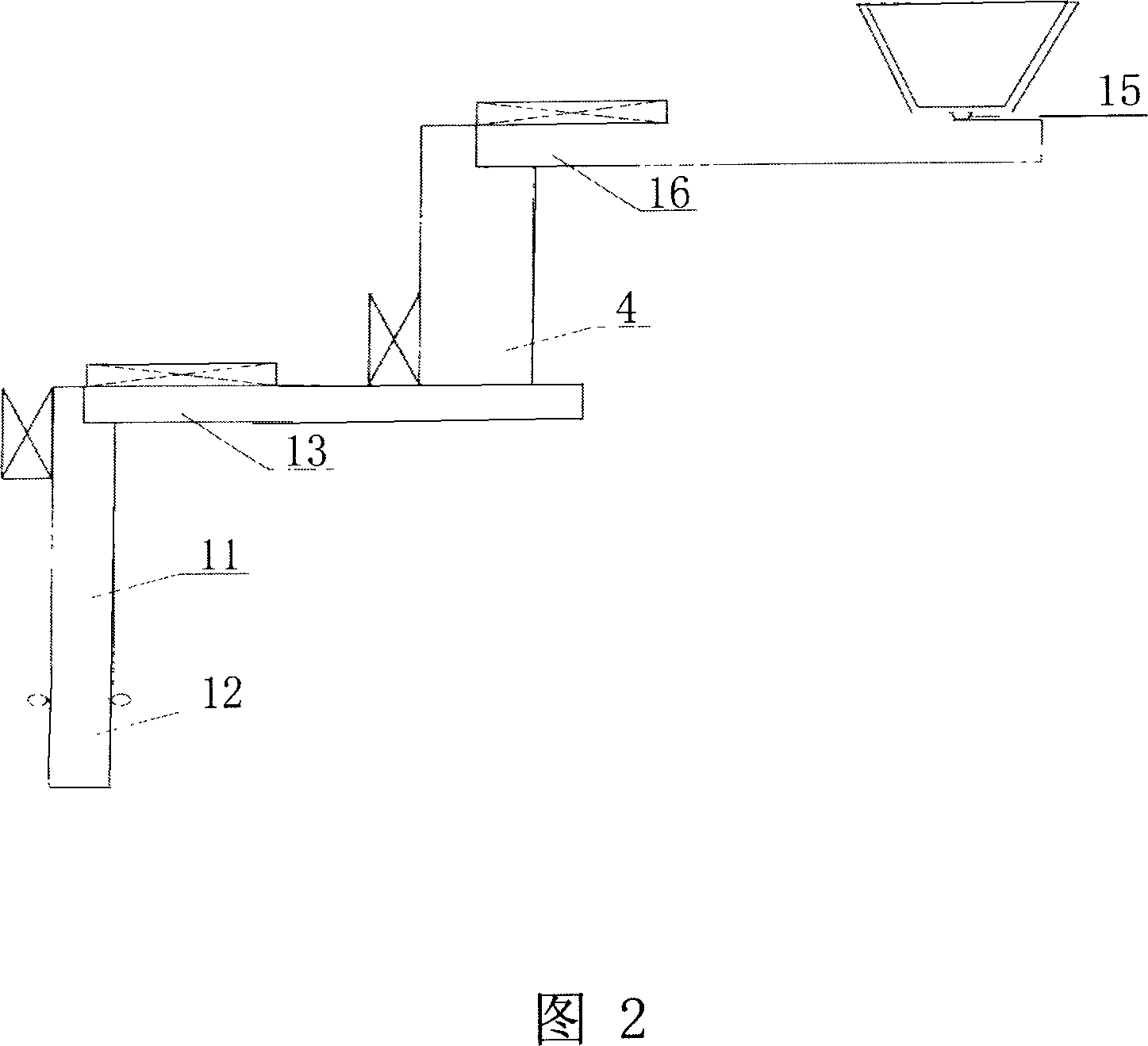

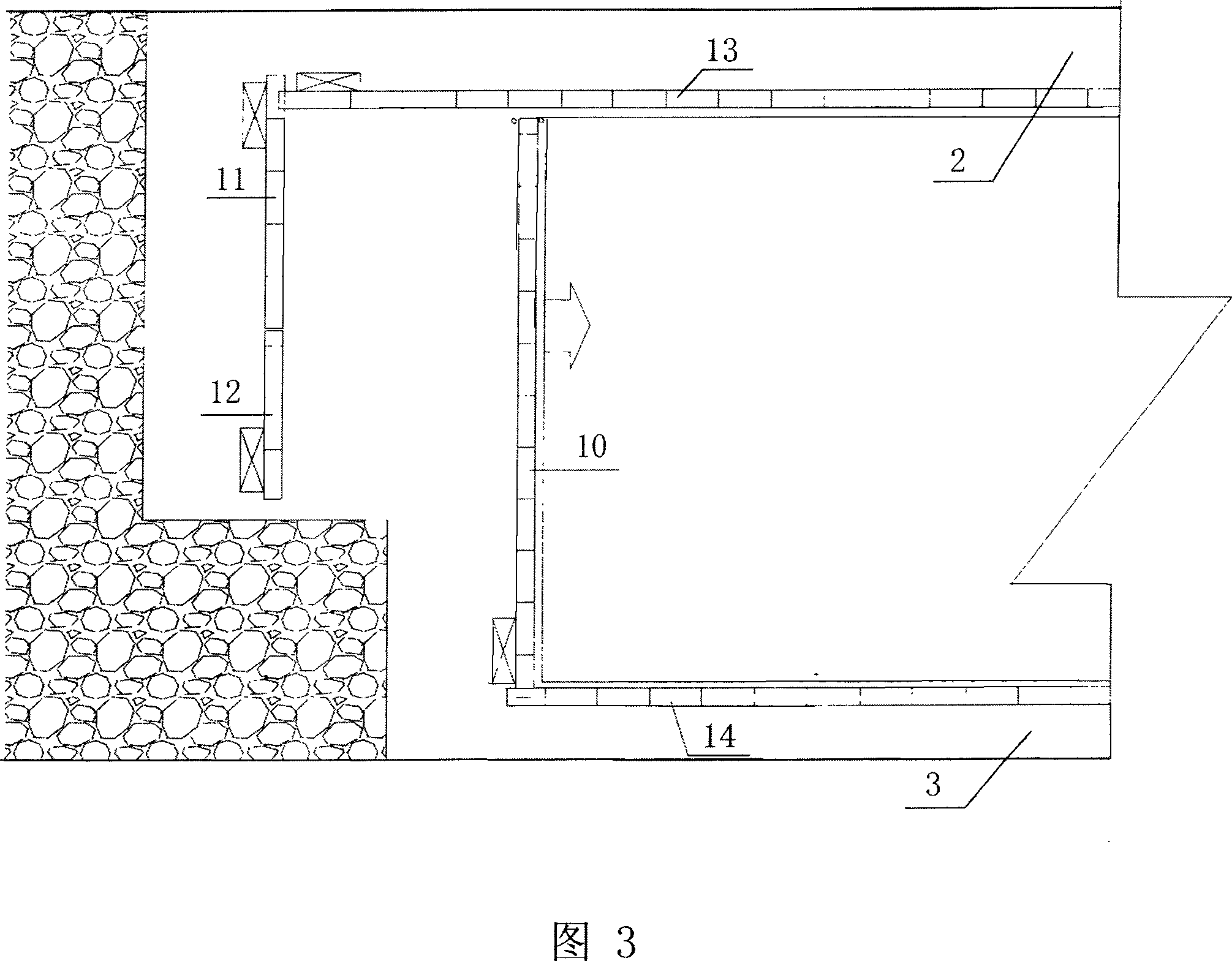

[0019] As shown in Fig. 1-Fig. 5, the present invention adopts no coal pillar mining, adopts the belt and scraper conveyor of the prior art to transport gangue, and the gangue belt throws gangue at high speed to realize the coal mine gangue filling of the mining face without coal pillar. Area. The raw gangue produced by each excavation of the mine head-on is directly transported to the gangue unloading lane 7 by a 1-ton mine car, and the gangue is turned over to the gangue bin 9 by the cantilever cart machine 8 jacked into the gangue bin 9, and a funnel is installed at the bottom of the gangue bin 9 The gate 15 is evenly discharged to the gangue transporting scraper conveyor 16 through the funnel gate 15, through the gangue transporting belt conveyor 4, the gangue transporting scraper conveyor 13 on the working face, the gangue transporting scraper conveyor 11 on the working face, Then the gangue is thrown to the goaf by the high-speed gangue belt 12. Because the filling width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com