Thin coal seam separated mining, separated conveying, filling and producing hydraulic support

A technology of separate mining and transportation and hydraulic support, which is applied in the direction of filling, mine roof support, mining equipment, etc., can solve the problem that the support cannot support the rock above the coal seam, so as to reduce the cost of washing, reduce the pressure of washing, and reduce the content of Quantity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solution of the present invention will be further described in detail below in conjunction with the description of the drawings and specific embodiments.

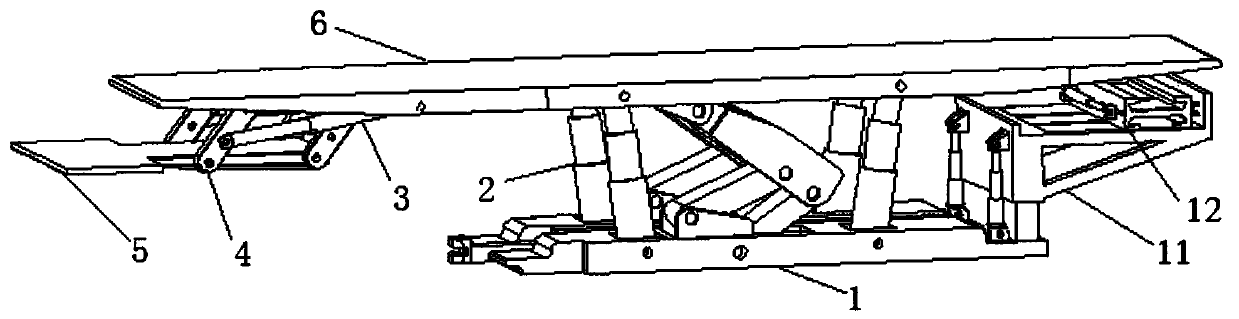

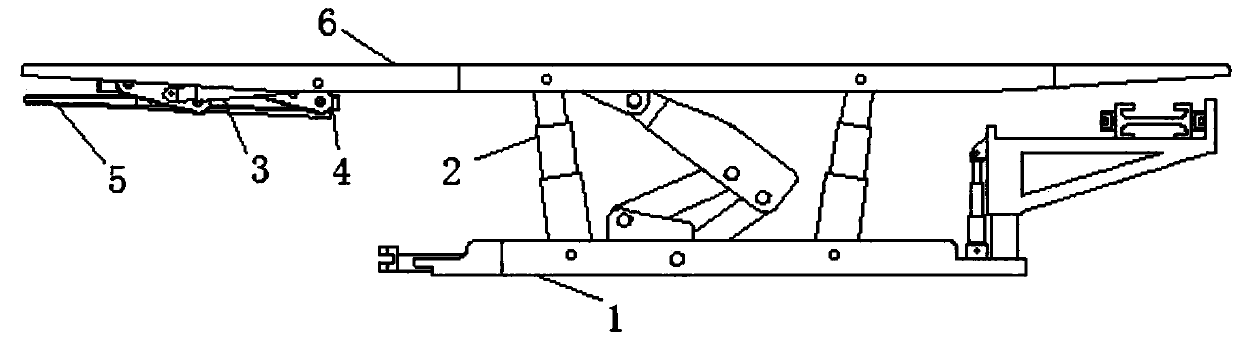

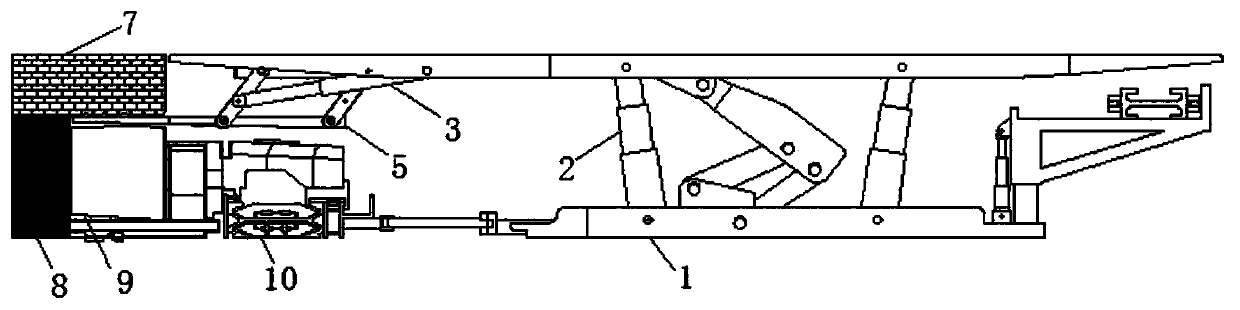

[0021] Such as figure 1 As shown, a thin coal seam separate mining, separate transportation, filling mining hydraulic support of the present invention includes a base 1, a top beam 6 is arranged above the base 1, a plurality of telescopic columns 2 are arranged between the base 1 and the top beam 6, and the top beam A support plate 5 that can extend forward is arranged under the front end of the top beam 6, and a filling scraper conveyor 12 is arranged behind the top beam 6.

[0022] to combine figure 2 , in a thin coal seam separate mining, separate transportation and filling mining hydraulic support of the present invention, a driving mechanism 3 is arranged on the top beam 6, and the driving end of the driving mechanism 3 is connected to the support plate 5; the driving mechanism 3 includes a conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com