Micro-fine particle hematite selective flocculation flotation method

A hematite and selective technology, which is applied in the field of selective flocculation flotation of fine-grained hematite, can solve the problems of low grade and low recovery rate of flotation concentrate, so as to solve production difficulties, improve grade and recovery rate , Reduce the effect of desliming operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

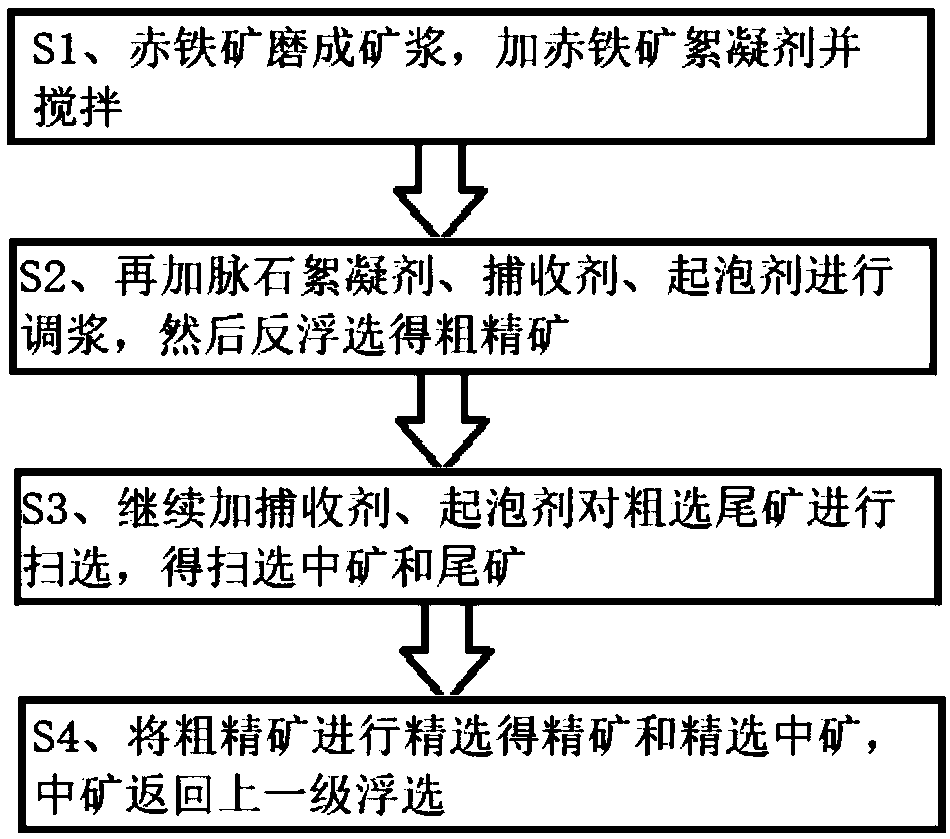

[0036] A kind of fine particle hematite selective flocculation flotation method of the present invention, carry out according to the following steps:

[0037] S1. Grinding the hematite into a slurry, the slurry flows into the stirring tank, first adding the hematite flocculant and stirring; specifically, starch is used as the hematite flocculant and inhibitor in this embodiment, and the starch includes but Not limited to corn starch, sweet potato starch, wheat starch, tapioca starch and the modified products of the aforementioned starches; the dosage A of hematite flocculant and inhibitor starch is 500-5000g / t raw ore;

[0038]S2, adding gangue flocculants, collectors and foaming agents to adjust the slurry, and the slurry after the adjustment flows into the flotation machine for hematite reverse flotation to obtain hematite coarse concentrate; specifically, this In the embodiment, polyoxyethylene is used as the gangue flocculant, dodecylamine is used as the collector, and ter...

Embodiment 2

[0046] A kind of selective flocculation flotation method of fine-grained hematite in this embodiment is basically the same as in Embodiment 1. Further, the molecular weight of polyethylene oxide in this embodiment is 300-12 million, which can realize the detection of gangue minerals. The effective flocculation and good selectivity can effectively reduce the impurity content in the flocs, and the use effect is excellent. Specifically, in this embodiment, the molecular weight of polyethylene oxide is 3 million; and in this embodiment, adding red After stirring the iron ore flocculant for 2 minutes, add the gangue flocculant, collector and foaming agent.

[0047] In this embodiment, the amount A of the hematite flocculant and the amount B of the gangue flocculant are controlled as Wherein coefficient a is (6-30), and the consumption C1 of coarse selection collector and the consumption A of hematite flocculant control in S2 step are Wherein the coefficient b is (10-25), the coe...

Embodiment 3

[0050] A kind of fine-grained hematite selective flocculation flotation method of the present embodiment is basically the same as embodiment 2, the difference is that the molecular weight of polyoxyethylene in the present embodiment is 12 million, in the present embodiment adding hematite After stirring the flocculant for 1 min, add gangue flocculant, collector and foaming agent.

[0051] The consumption A of hematite flocculant starch in the present embodiment is 3000g / t raw ore; The roughing foaming agent dosage D1 in the step is 26g / t raw ore; the sweeping collector dosage C2 in the S3 step is 200g / t raw ore; the sweeping foaming agent dosage D2 in the S3 step is 20g / t raw ore; The amount A of the ore flocculant and the amount B of the gangue flocculant are controlled as In the S2 step, the consumption C1 of the coarse collector and the consumption A of the hematite flocculant are controlled as In step S2, the ratio of the amount D1 of the roughing foaming agent to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com