Patents

Literature

34results about How to "Reduce finishing process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

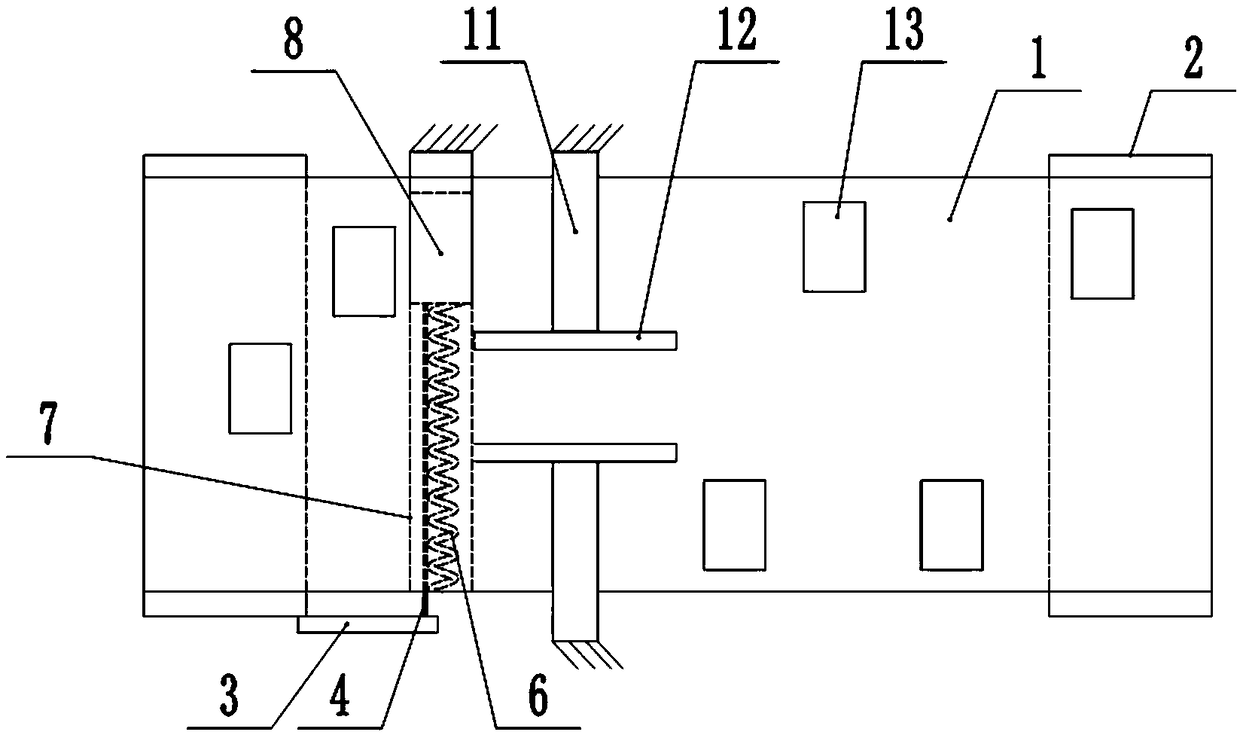

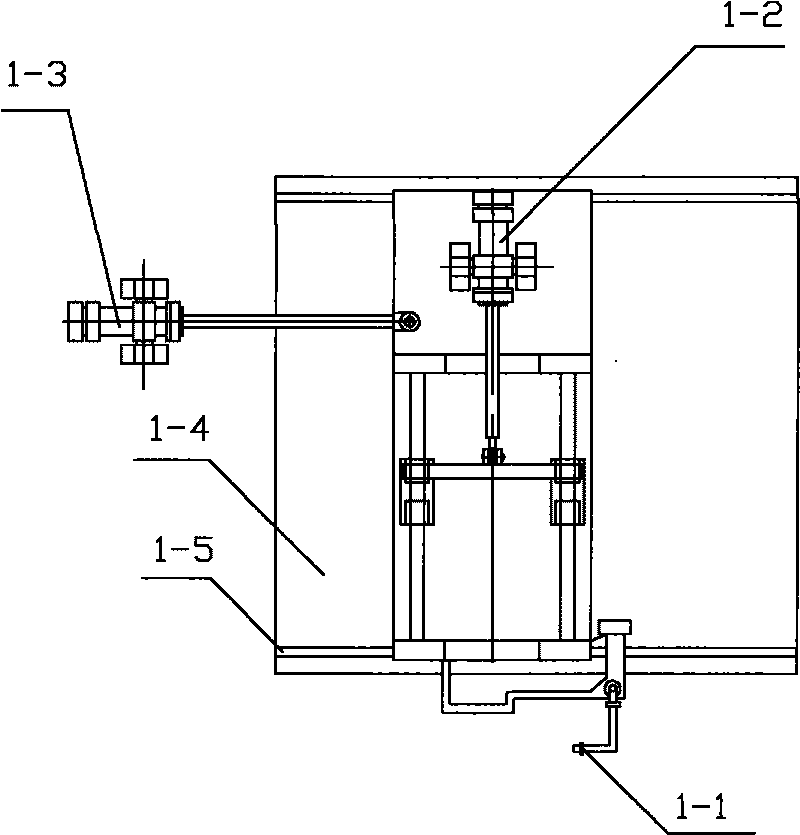

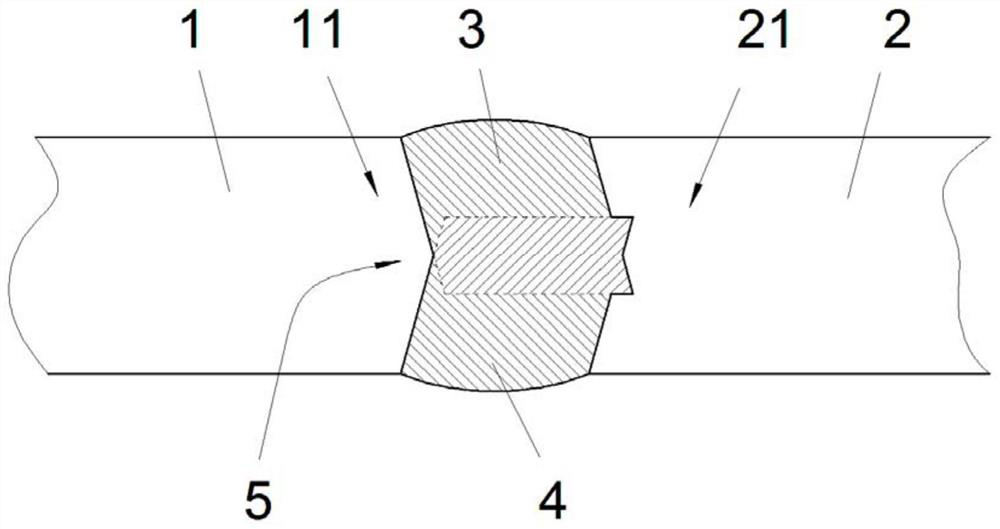

Computer part transportation mechanism

ActiveCN108792422AAvoid damageImprove securityConveyorsContainers to prevent mechanical damageSlide plateAir cavity

The invention relates to the field of transportation, and discloses a computer part transportation mechanism. The mechanism comprises a rack, a conveyer belt, a plurality of tote boxes; grooves are formed in the tote boxes; placing plates are glidingly connected in the grooves; a cylinder body is mounted in a lower groove; two sliding plates are glidingly connected in the cylinder body; a dust collection chamber is formed between the surfaces, far away from an extrusion chamber, of the sliding plates and the cylinder body; the dust collection chamber is communicated with an air cavity; movinggrooves are formed in two sides of the bottom of the placing plate; first struts are fixed on the surfaces, far away from the extrusion chamber, of the sliding plates; one ends of the first struts penetrate through the dust collection chamber and are glidingly connected in the moving grooves; movable cavities are formed in both two sides of the groove; each movable cavity is internally provided with an extrusion air bag, an oscillating bar and a support rod; and the end of the placing plate penetrates into the movable cavities and is hinged with one ends, far away from a cross bar, of the oscillating bar. According to the mechanism, computer parts can be prevented from being damaged in the transportation process so that the computer part transportation safety is improved, and ash removal can be carried out on the computer parts so that the cleanliness of the computer parts is improved.

Owner:湖南湘江鲲鹏信息科技有限责任公司

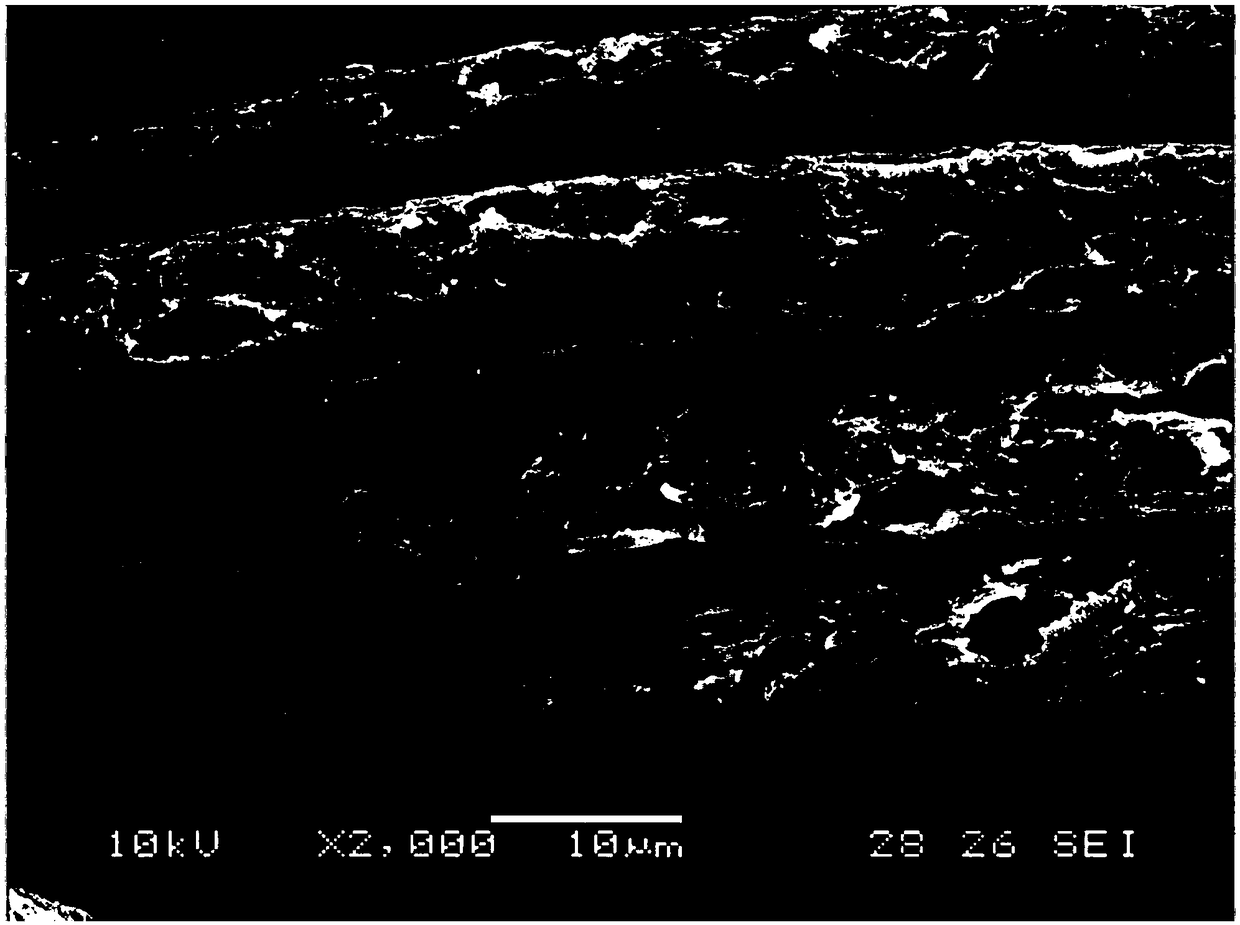

Preparation method of antibacterial PVC polyester coated filament

ActiveCN106380719AEnhanced stiff feelReduce finishing processYarnSynthetic polymer filament chemical after-treatmentMasterbatchPolyester

The invention relates to a preparation method of an antibacterial PVC polyester coated filament. The method consists of: 1) color masterbatch preparation: weighing the following raw materials; putting the raw materials into a high-speed mixer to conduct high speed mixing; carrying out stirring cooling to 50DEG C, then transferring the mixture into a hopper, and sending the hopper into a host hopper by a conveying device; cutting the mixture into particles by a pelletizer, thus obtaining color masterbatch; 2) coating: putting polyester filament into a filament rack, penetrating a mold by a tensioner positioning device, and mounting the mold into a diverter; adding the color masterbatch into a hopper, carrying out heating plasticizing, then bringing the color masterbatch to the diverter by a host motor; letting a traction disc drive the polyester filament to perform coating through the diverter; and conducting cooling with cooling water, then bringing the filament into an automation line, performing detection, and then conducting rolling-up. The carrier resin with polyvinyl chloride as the color masterbatch is added with an antibacterial nano material, the polyester filament is colored, and is also endowed with good antibacterial properties. The stiffness handfeel of the polyester filament is enhanced, and the finishing process of additional application of a stiffening agent in a follow-up processing process of polyester window decorations can be eliminated.

Owner:浙江西大门新材料股份有限公司

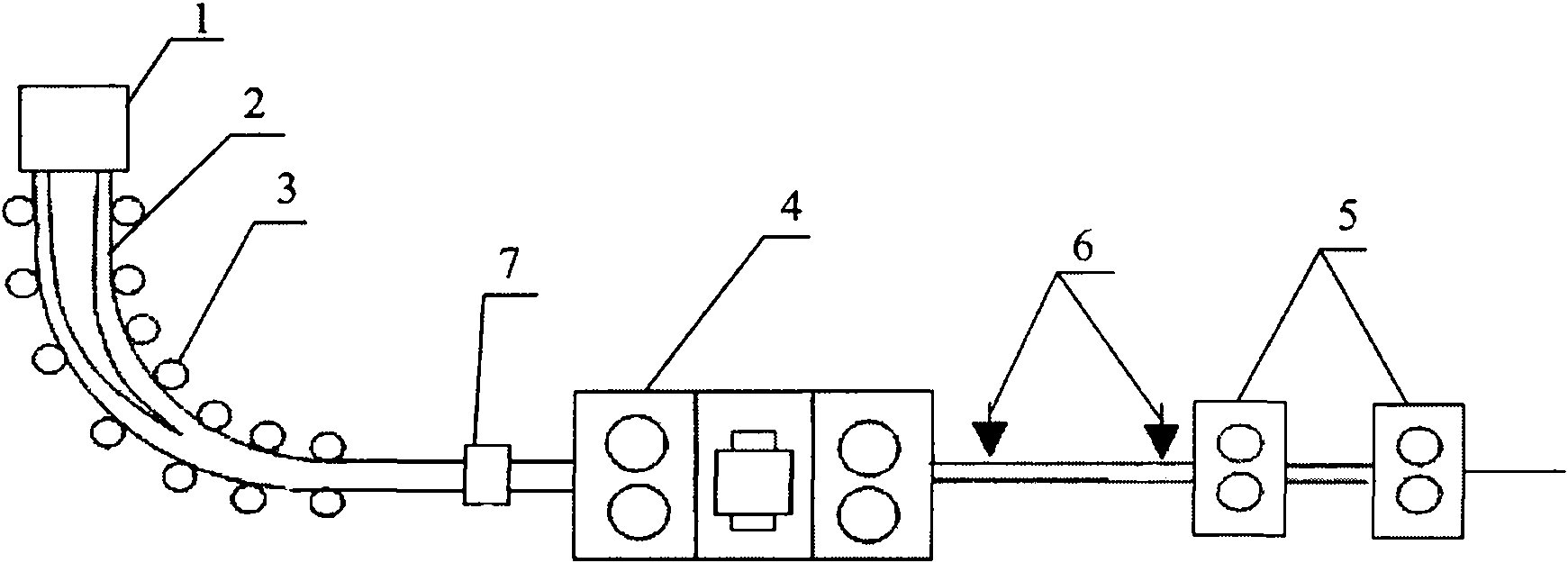

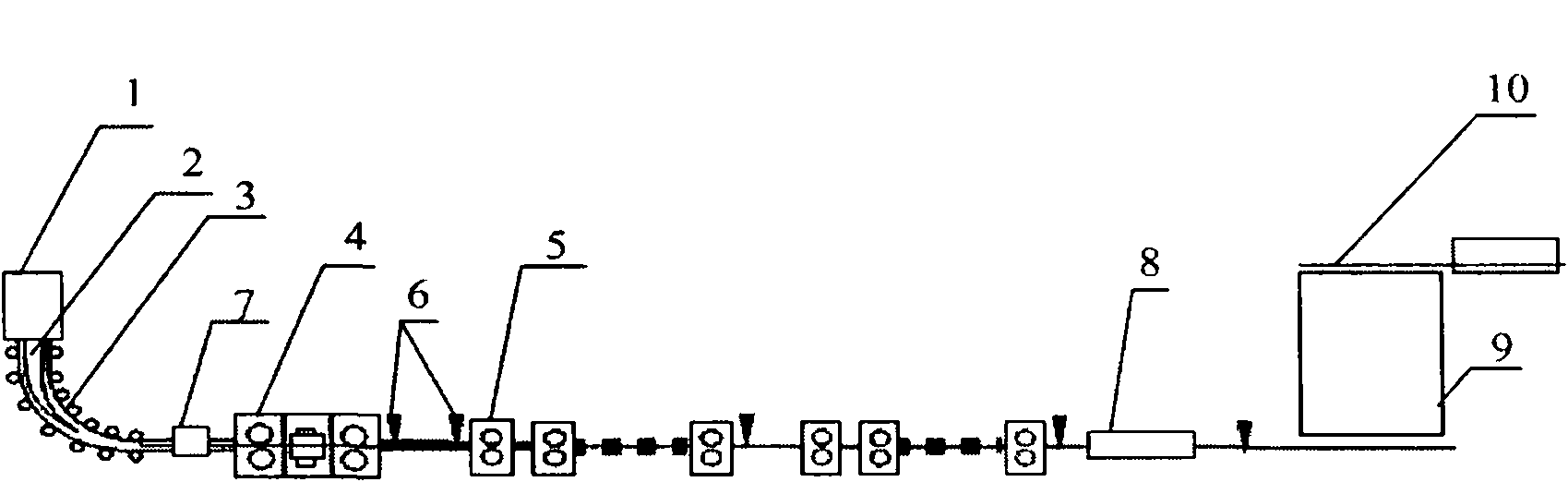

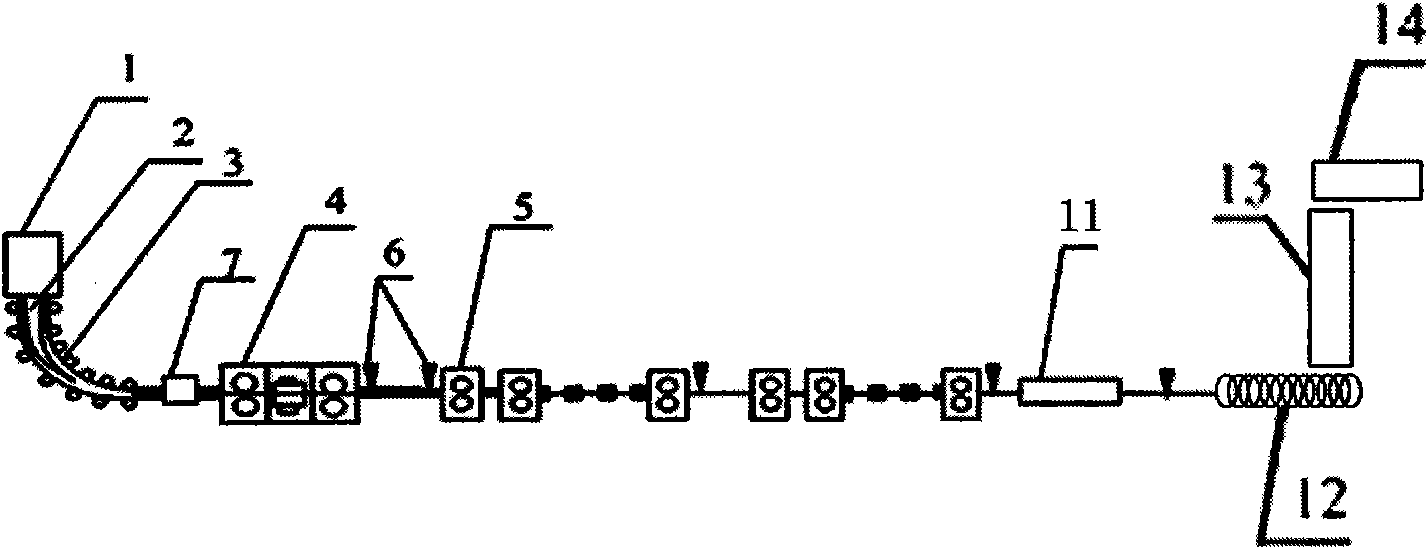

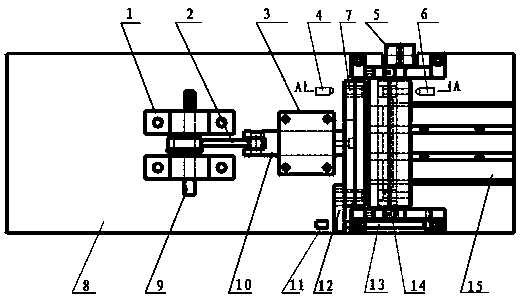

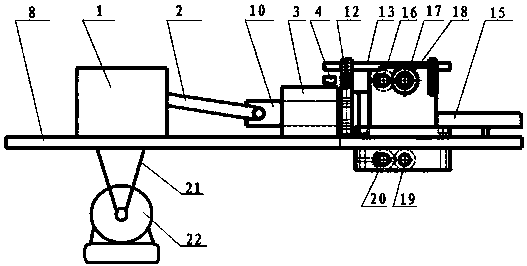

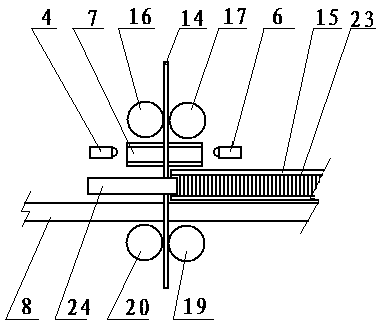

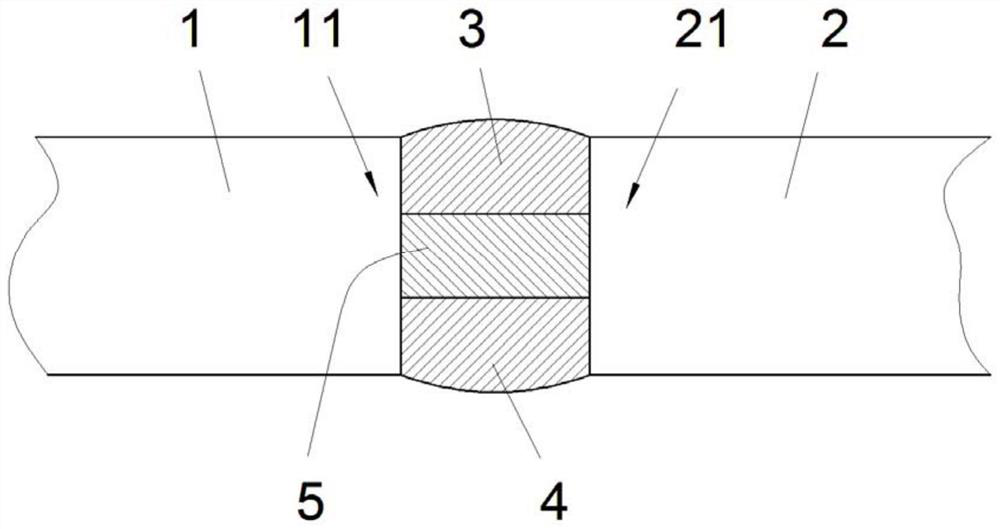

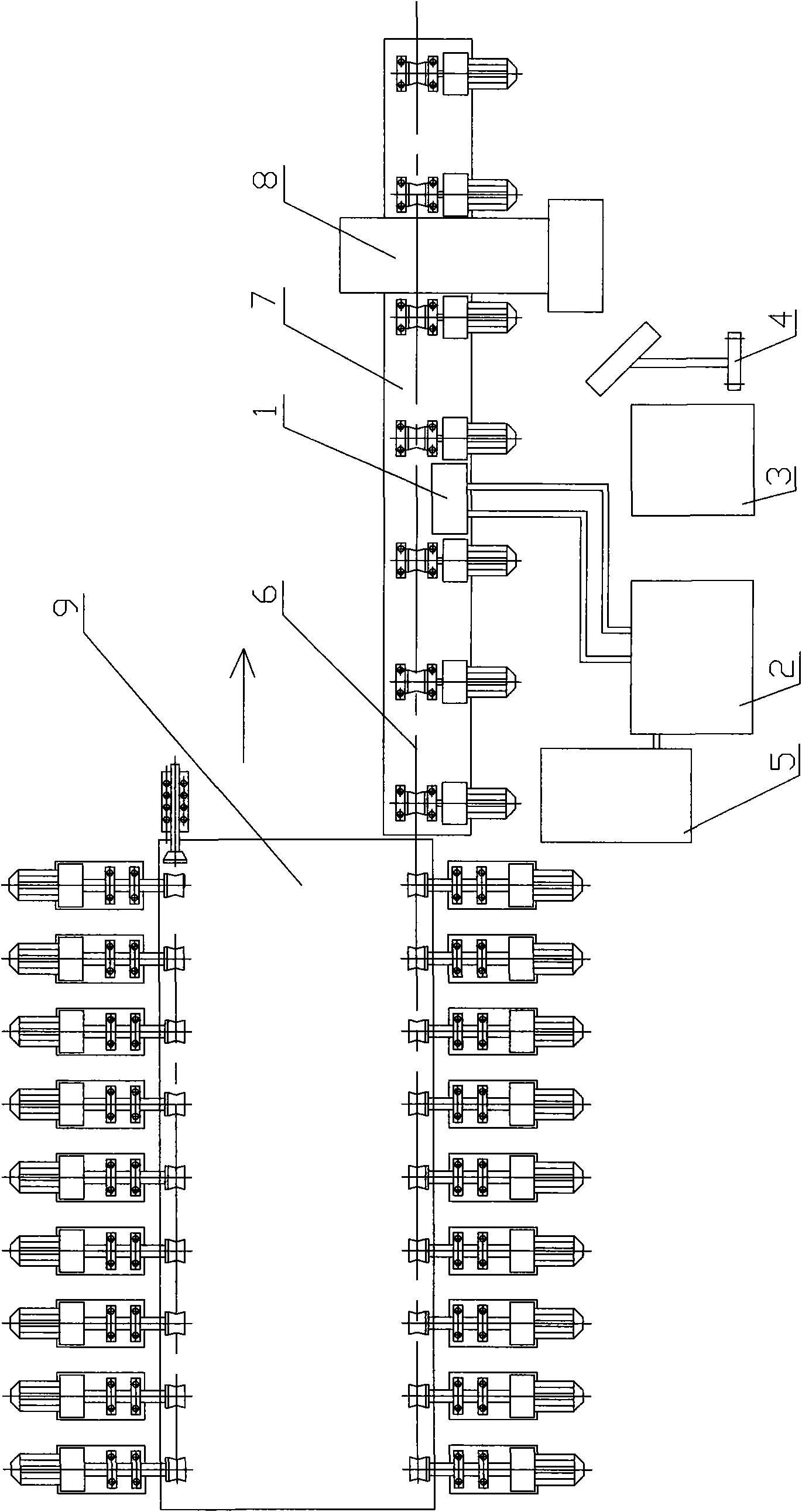

Method for endless rolling of sectional material and rod and wire material and flexible connecting device thereof

ActiveCN101829678ASolve the speed problemFix speed mismatchMetal rolling stand detailsMetal rolling arrangementsWire rodProduction line

The invention discloses a method for endless rolling of sectional material and rod and wire material and a flexible connecting device thereof, which realize seamless connection of all-line rolling and continuous molding from crystallizers to finished products. The invention comprises that a flexible connecting rolling mill device is arranged on a conventional continuous casting-continuous rolling production line, wherein the flexible connecting rolling mill device is in three forms: one consists of a soft pressure lower roll system; one consists of a high pressure lower roll mechanism; and one consists of the soft pressure lower roll system and the high pressure lower roll mechanism together. The flexible connecting rolling mill device is arranged between the crystallizers and the conventional continuous rolling mills in one of the three forms. The method for the endless rolling of the sectional material and rod and wire materials and the flexible connecting device thereof save three processes of continuously cast bloom cutting, secondary heating and welding, realize the seamless connection and flexible connection between the continuous casting and continuous rolling, shorten the production flow and the production line length, simplify the operation, and provide a new way for the metallurgy production to realize the energy and resource conservation, reduce the carbon emission, reduce the cost and improve the product quality and competitiveness.

Owner:鞍山源鑫钢铁有限公司

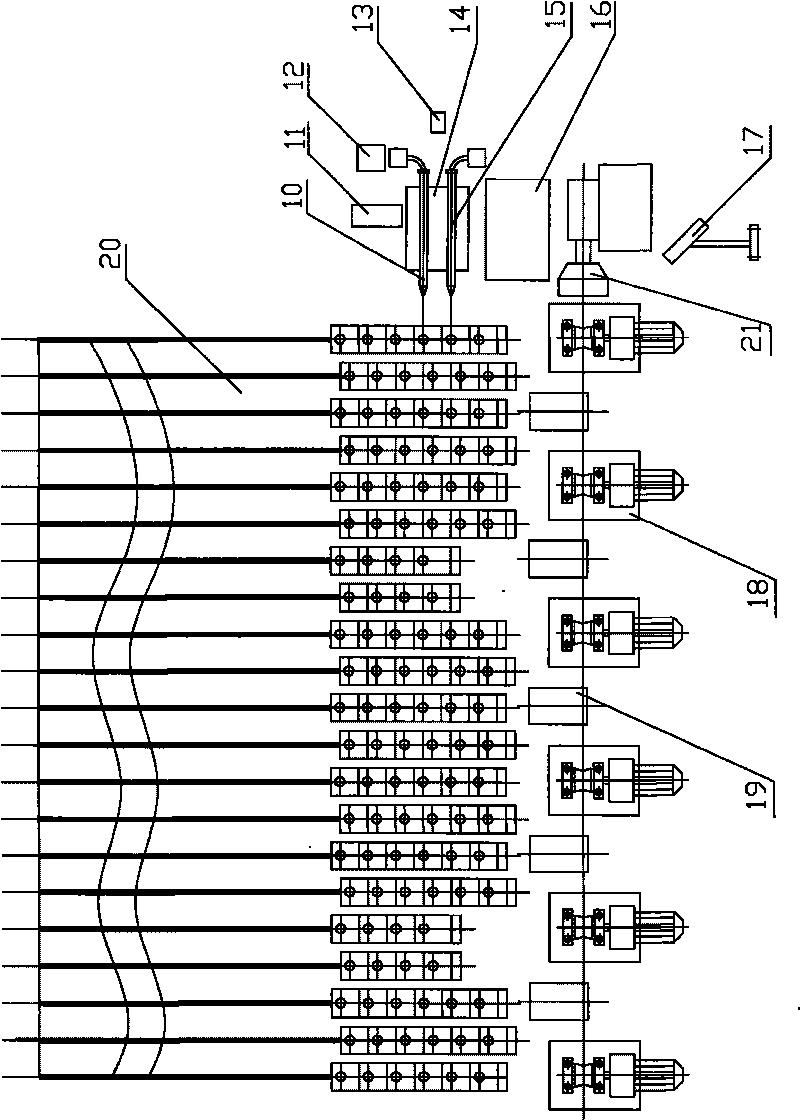

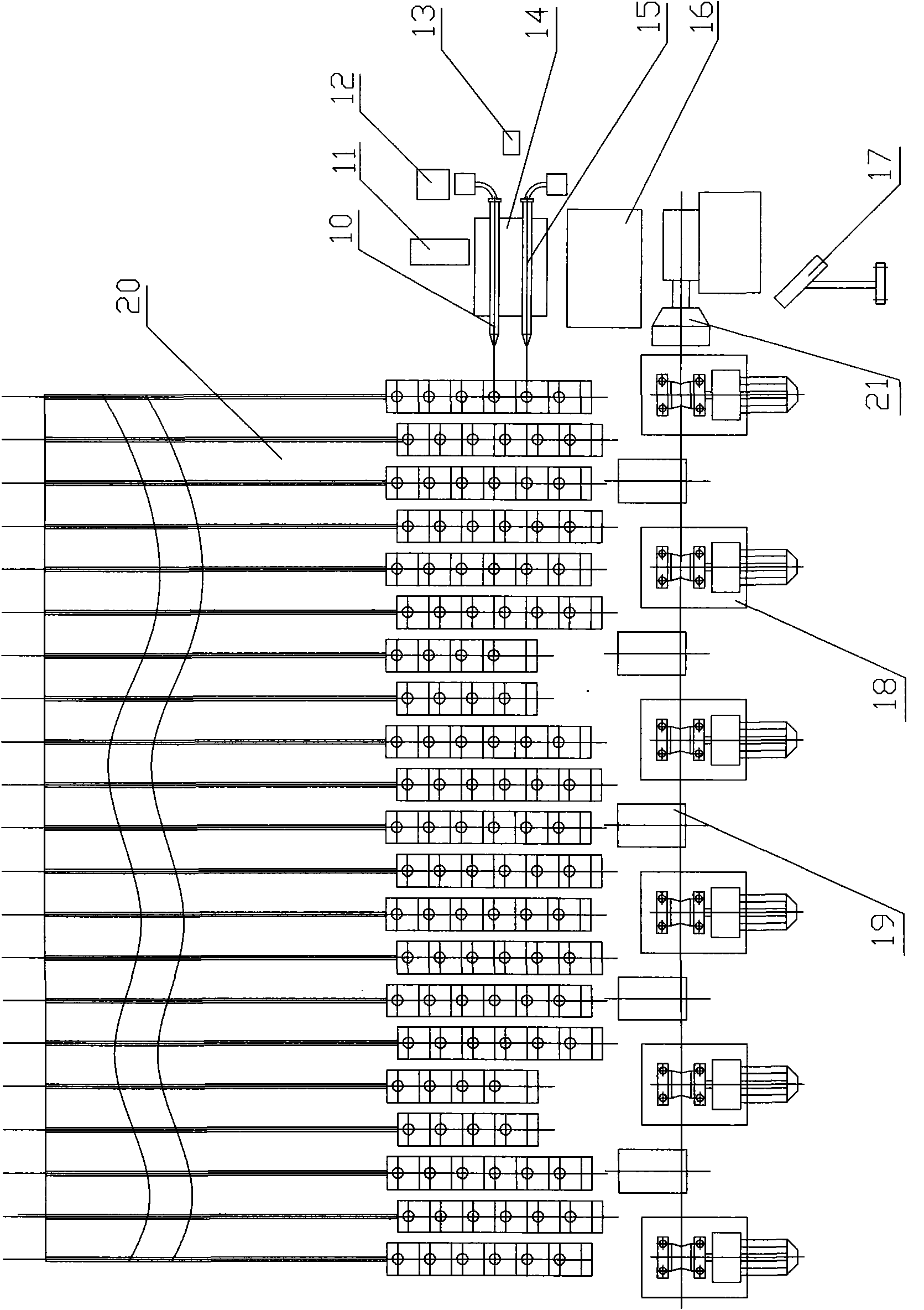

Method and device for removing inner surface oxidized iron sheet of steel pipe on line

ActiveCN101700532AReduced finishing processIncrease costWork treatment devicesMetal rolling arrangementsSlagSteel tube

The invention relates to a method and a device for removing an inner surface oxidized iron sheet of a steel pipe on line. A device for removing an inner surface oxidized iron sheet of a steel pipe from the tail of the steel pipe is arranged behind a stepping type reheating furnace, and the inlet section of a stepping type cooling bed is provided with a device for removing the inner surface oxidized iron sheet of the steel pipe from the head of the steel pipe. After the tail and the head of the steel pipe are detected by a hot metal detector, the device for removing the inner surface oxidized iron sheet of the steel pipe from the tail of the steel pipe sprays high-pressure water to an inner hole of the tail of the steel pipe and removes the oxidized iron sheet of the inner hole of the steel pipe, and the device for removing the inner surface oxidized iron sheet of the steel pipe from the head of the steel pipe sprays high-pressure water and a high-pressure gas to the inner hole of the head of the steel pipe so as to remove oxidized slag retained in the inner hole of the steel pipe. The inner surface oxidized iron sheet of the steel pipe is removed on line behind the stepping type reheating furnace and at the inlet section of the stepping type cooling bed, and the finishing procedure of the rear part of the steel pipe is reduced. The invention not only saves the cost of acid washing, shot blasting and grinding but also improves the production efficiency.

Owner:HENGYANG VALIN STEEL TUBE +1

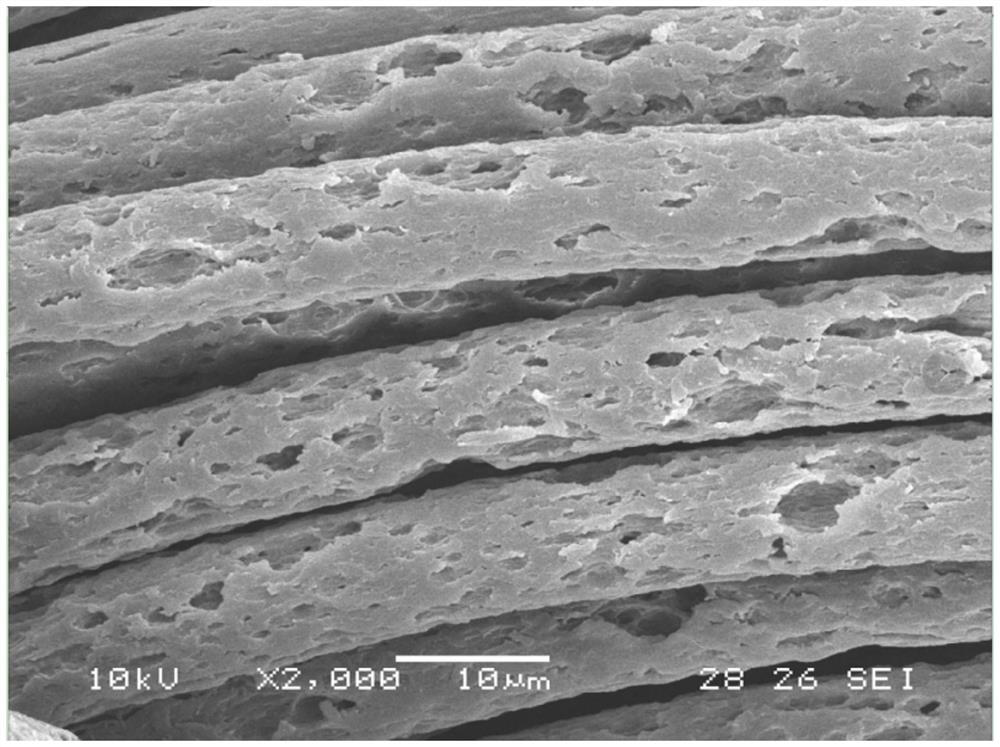

Anti-ultraviolet and moisture-absorption quick-dry yarn, and production technology and application thereof

ActiveCN109112688AIncreased durabilityReduce finishing processYarnMonocomponent polyesters artificial filamentFiberYarn

The invention relates to the production technology of an anti-ultraviolet and moisture-absorption quick-dry fabric. The technology is characterized by firstly, adopting a polyester resin and an addition agent to melt, extruding, and pelletizing to make polyester chips; then, through a spinning technology, forming a fine denier polyester staple fiber; and then, through siro spinning and weaving technologies, an alkali decrement technology and the like, making a finished product. The anti-ultraviolet and moisture-absorption quick-dry fabric has advantages that a lot of micropores and channels are distributed on a surface so that the fabric has a high capillary effect; sweat can be quickly transferred to an outer groove through the micropores so as to form a moisture-absorption quick-dry effect; and an environment-friendly ultraviolet absorbent, a shielding agent and the polyester chips are fused, and a high-performance anti-ultraviolet and moisture-absorption quick-dry fabric after a special spinning technology is formed.

Owner:ZHEJIANG LANTIANHAI FAB TECHNOLAGY CO LTD

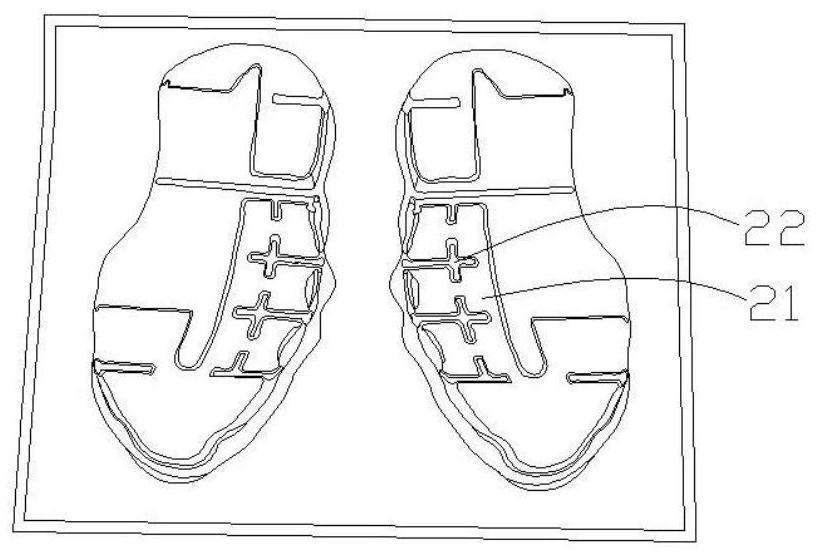

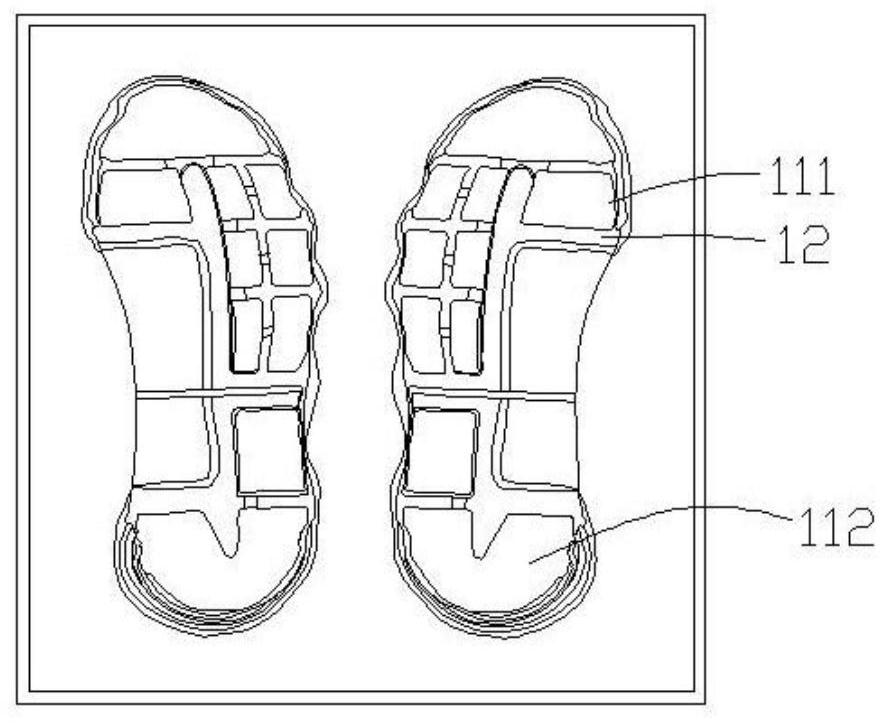

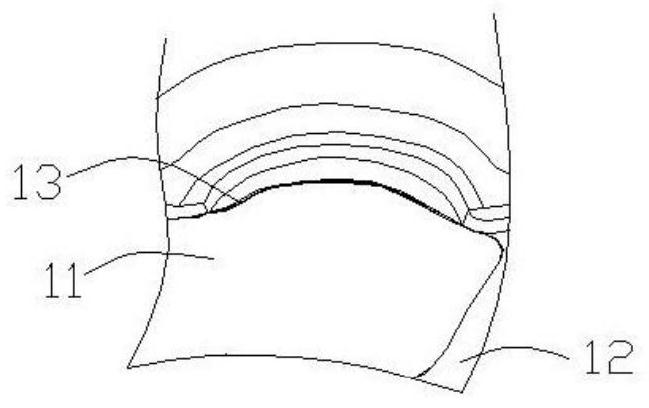

Bio-based rubber sole as well as preparation method and mold thereof

ActiveCN113444302AImprove mechanical propertiesIncrease the degree of cross-linkingSolesDomestic footwearRubber materialPolymer science

The invention discloses a bio-based rubber sole. The bio-based rubber sole comprises the following components in parts by weight: 40 parts of bio-based solution polymerized styrene-butadiene rubber, 16 to 24 parts of a bio-based ethylene propylene diene monomer, 38 to 46 parts of natural rubber, 35 to 40 parts of white carbon black, 2.1 to 2.8 parts of a silane coupling agent, 0.7 to 1.1 parts of stearic acid, 0.6 to 0.9 part of an anti-aging agent, 1.9 to 2.5 parts of an active agent, 3.2 to 3.8 parts of zinc oxide, 0.7 to 1.5 parts of polyethylene wax, 1.0 to 1.8 parts of an anti-frosting agent, 0.9 to 1.4 parts of tackifying resin, 1.2 to 1.8 parts of vulcanization accelerator, and 1.9 to 2.3 parts of insoluble sulfur. When the bio-based solution polymerized styrene-butadiene rubber is prepared and polymerized, carboxylated solution polymerized styrene-butadiene rubber, zinc oxide, stearic acid and epoxidized soybean oil are internally mixed in an internal mixer to construct an ester group cross-linked network structure, and the advantage that oil is not separated out is achieved. Besides, during vulcanization molding, ion pairs formed by zinc ions and carboxyl groups in a rubber material can be used as reinforcing points, so a crosslinking degree is improved, and the mechanical property of a bio-based rubber outsole is improved.

Owner:MAOTAI FUJIAN SOLES CO LTD +1

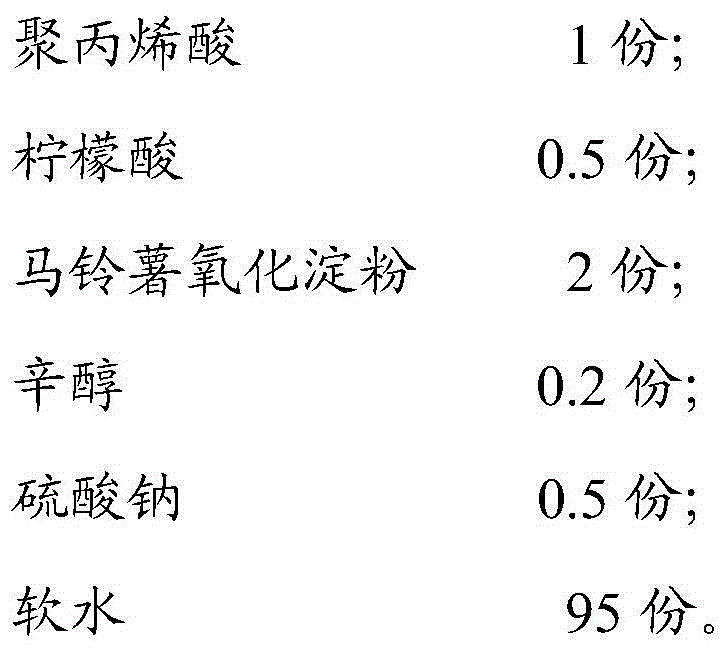

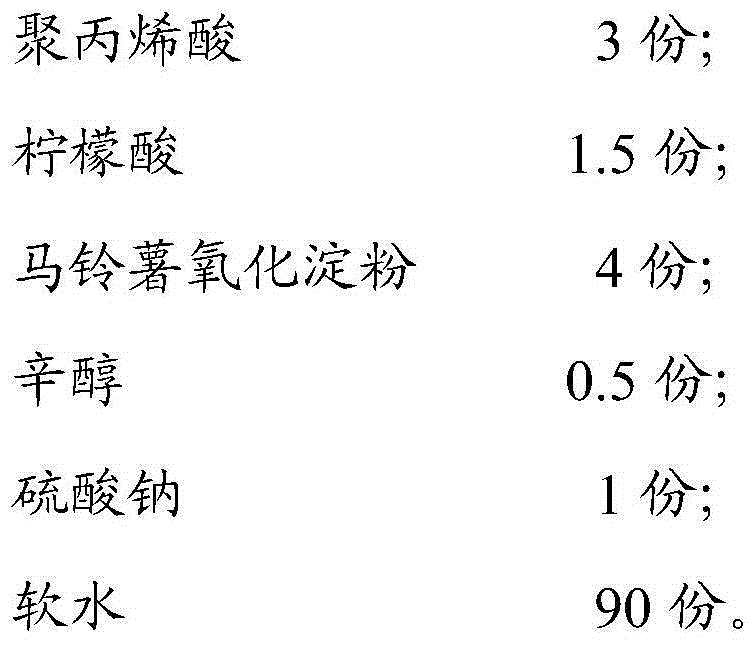

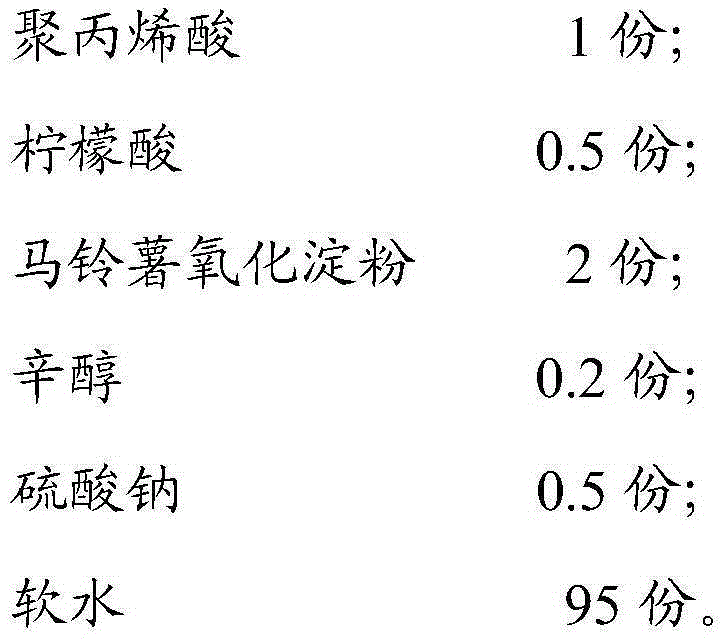

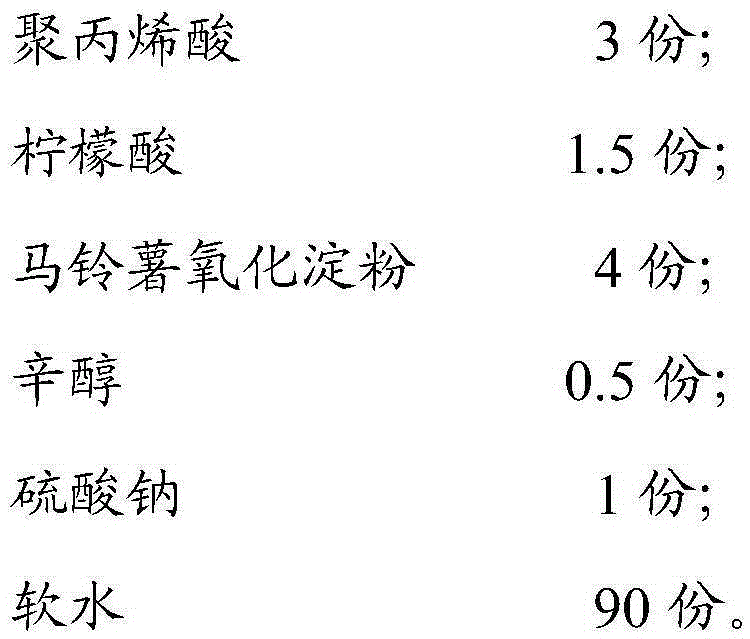

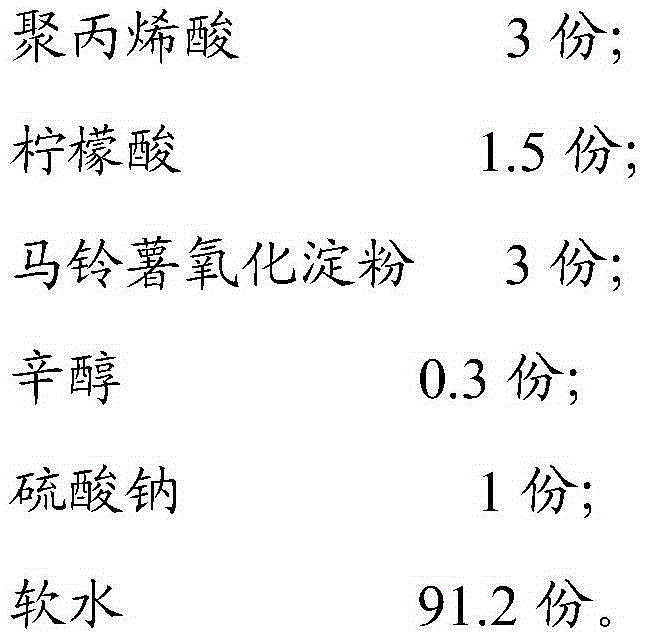

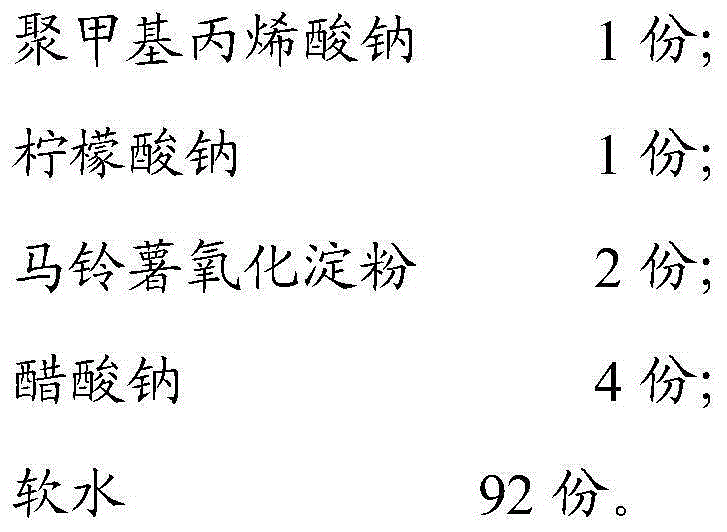

Sizing agent combination

ActiveCN104141248AImprove wrinkle resistanceColor depthDyeing processAgent CombinationPulp and paper industry

The invention discloses a sizing agent combination which comprises, by weight, 1-3 parts of thickener, 0.5-1.5 parts of crease-resistant agent, 2-4 parts of potato oxidized starch, 0.2-0.5 part of antifoaming agent, 0.5-1 part of leveling agent and 90-95 parts of water. By means of the synergistic effect of all the constituents, the water retention capacity and viscosity of the sizing agent combination are improved, and the dyeing effect of dye-based ink is good. Fabric subjected to digital printing by means of the sizing agent combination can be colored deeper and brighter, the color design is clear, and stain bleeding is avoided. Due to the adoption of the crease-resistant agent, the crease resistance of silk and wool blended fabric is improved greatly, the finishing process conducted after the silk and wool blended fabric is printed is omitted, and energy is saved. Due to the adoption of the antifoaming agent, even sizing is achieved by means of the sizing agent combination, no foam is generated, and the printing effect is improved.

Owner:佛山市三水嘉骏纺织染有限公司

Method for improving color fastness of polyester spandex single-sided polar fleece fabric

InactiveCN107630309AIncrease elasticityGuaranteed high elasticity of the fabricSucessive textile treatmentsHeating/cooling textile fabricsColour fastnessPolyester

The invention relates to a method for improving the color fastness of a polyester spandex single-sided polar fleece fabric. The method includes the pre-treatment process, the dyeing process, the cleaning process, the auxiliary adding process, the drawing process, the middle shaping process, the carding process, the shearing process and the post-treatment process. The whole process integrates the stability of the fabric and the high color fastness guarantee, so that the anti-pilling style is more attractive; meanwhile, the post-finishing procedure is omitted, the energy consumption is reduced,and the special requirement of equipment is avoided; the processed fabric is good in style, good in elasticity, good in hand feeling, good in fastness, good in pilling resistance and capable of achieving production stability, and technical problems in polyester spandex polar fleece fabric color fastness processing and production are solved.

Owner:SHANGHAI CHALLENGE TEXTILE

Method for endless rolling of sectional material and rod and wire materials

ActiveCN101829678BFix speed mismatchReduce lossesMetal rolling stand detailsMetal rolling arrangementsProduction lineEngineering

Owner:辽宁中车轨道交通装备有限公司

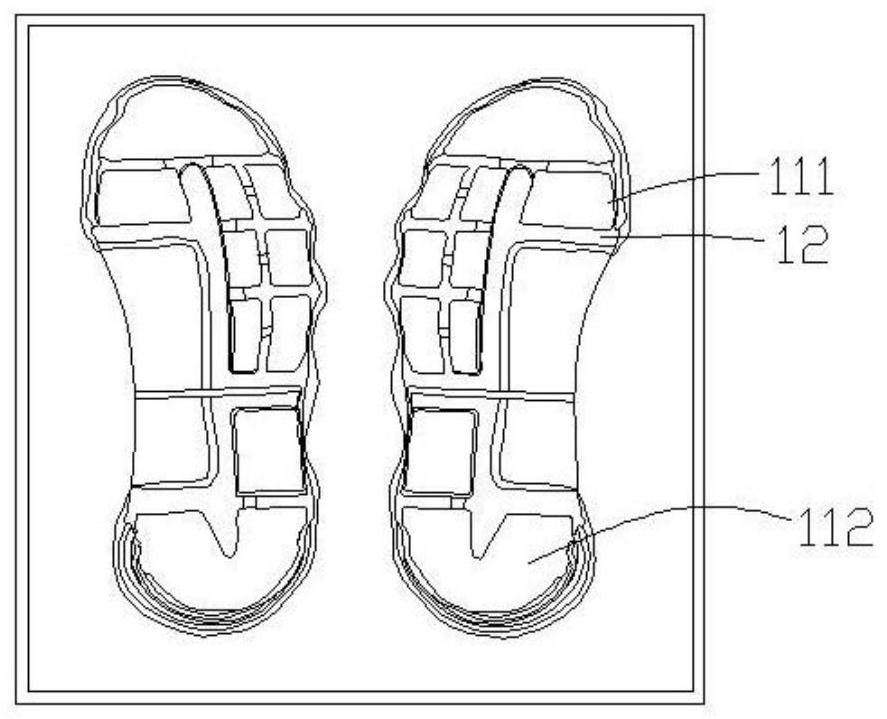

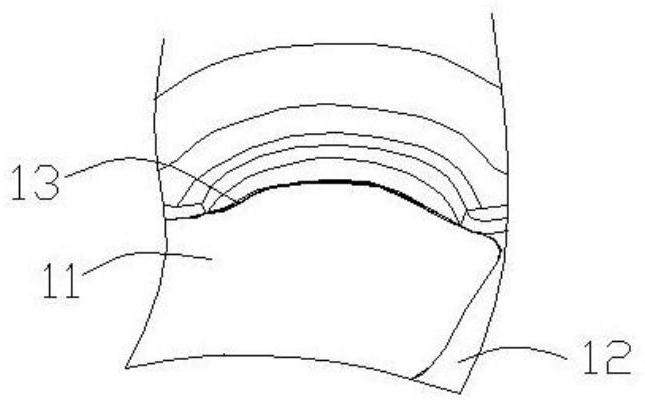

Anti-slippery bio-based rubber sole and preparation method and mold thereof

ActiveCN113444303AImprove mechanical propertiesIncrease the degree of cross-linkingSolesDomestic footwearRubber materialPolymer science

The invention discloses an anti-slippery bio-based rubber shoe sole and a preparation method and a mold thereof. The anti-slippery bio-based rubber shoe sole comprises the following components in parts by weight: 50 parts of bio-based solution polymerized styrene-butadiene rubber, 26 to 34 parts of carboxylated nitrile rubber, 16 to 24 parts of epoxidized natural rubber, 35 to 50 parts of white carbon black, 2.1 to 2.8 parts of a silane coupling agent, 1.2 to 1.5 parts of stearic acid, 1.0 to 1.3 parts of an anti-aging agent, 1.9 to 2.5 parts of an active agent, 4 to 6 parts of zinc oxide, 1.2 to 1.5 parts of polyethylene wax, 1.4 to 1.8 parts of an anti-frosting agent, 1.3 to 1.7 parts of tackifying resin, 1.0 to 1.2 parts of a vulcanization accelerator, and 1.1 to 1.5 parts of insoluble sulfur. When the bio-based solution polymerized styrene-butadiene rubber is prepared and polymerized, carboxylated solution polymerized styrene-butadiene rubber, zinc oxide, stearic acid and epoxidized soybean oil are internally mixed in an internal mixer to construct an ester group cross-linked network structure, and the advantage that oil is not separated out is achieved. Besides, during vulcanization molding, ion pairs formed by zinc ions and carboxyl group in a rubber material can be used as reinforcing points, so a crosslinking degree is improved, and the mechanical properties of a bio-based rubber outsole are improved.

Owner:MAOTAI FUJIAN SOLES CO LTD +1

Preparation method and application process of anionic block silicone oil capable of being dyed in one bath

PendingCN113372558APrevent precipitationAvoid the problem of stains and spotsGrip property fibresVegetal fibresOrganosolvCarboxylic acid

The invention discloses a preparation method and an application process of anionic block silicone oil capable of being dyed in one bath, and the preparation method comprises the following steps: carrying out condensation reaction on double-end epoxy silicone oil, polyether amine and polyethylene polyamine in an organic solvent to obtain amino-terminated ternary block silicone oil; and adding dicarboxylic anhydride into the amino-terminated ternary block silicone oil, stirring for reaction, and adding an alcohol amine compound to obtain an anion modified ternary block silicone oil softener. The method has the advantages that the block silicone oil is subjected to anion modification, so that the organic silicon softening agent can be self-emulsified and dispersed in water, and the ionic property of the organic silicon softening agent is the same as that of raw materials in pretreatment and dyeing processes, so that the problem of material precipitation caused by mutual adsorption of anions and cations is avoided, and a dyeing and softening one-bath process is realized; therefore, the after-finishing process is reduced, the production efficiency is greatly improved, and the problems of color spots and color spots frequently occurring in the after-finishing process are also avoided.

Owner:广州安之信化工有限公司

Natural plant fibre extraction by alkali oxidation

InactiveCN100430533CReduce the probability of residual glueLow lignin contentFibre treatment to obtain bast fibrePlant fibreOxygen

The invention provided an alkaline extracting method of the natural plant fiber. The process is: the material->acid etch->washing->alkaline with oxygen->strike the fiber->washing by the water->washing by the acid->washing by the water->dehydration->shake the fiber->oil feed->dehydration->air dry or oven dry. The fiber can be protected by adding the assistant Mg<2+>, the stability of the H2O2 in the alkali and the chemical assistant, also the nucleophilic reaction of the H2O2 to lignine can reach the best efficient. It can be used for extracting the plant fiber of the spinning, weaving and the dressing.

Owner:QINGDAO UNIV

Cord fabric dipping and curing technology based on electronic radiation processing

The invention relates to a cord fabric dipping and curing technology based on electronic radiation processing. Sodium hydroxide, resorcinol and formaldehyde are condensed in water at the room temperature to be prepared into a solution (1); the solution (1) is added into butadiene vinyl-pyridine rubber latex, a JU-6 fiber activity adhesive is added after curing, and a solution (2) is prepared; the solution (2) and TMPTA / PETA resin of a trifunctional group or EGDMA / JPGDA resin of a bifunctional group are mixed and uniformly dispersed in a vacuum reaction kettle at a high speed at the room temperature, and a radiation-sensitive dipping finishing agent is prepared; the radiation-sensitive dipping finishing agent is added into a dipping machine, processed on a terylene / chinlon chemical fiber fabric by a single-dip single-roll process and cured by an electronic beam radiation device with the energy level higher than 400 KeV, and a dipped cord fabric is obtained. Dipped resin which can be affiliative with chemical fibers and rubber can be selected and wholly and quickly participates in a cross-linking reaction under the radiation condition, the curing is rapid, the curing time is short, energy consumption is low, the pretreatment efficiency is high, the flow path is short, and the cost is low.

Owner:JIHUA 3509 TEXTILE

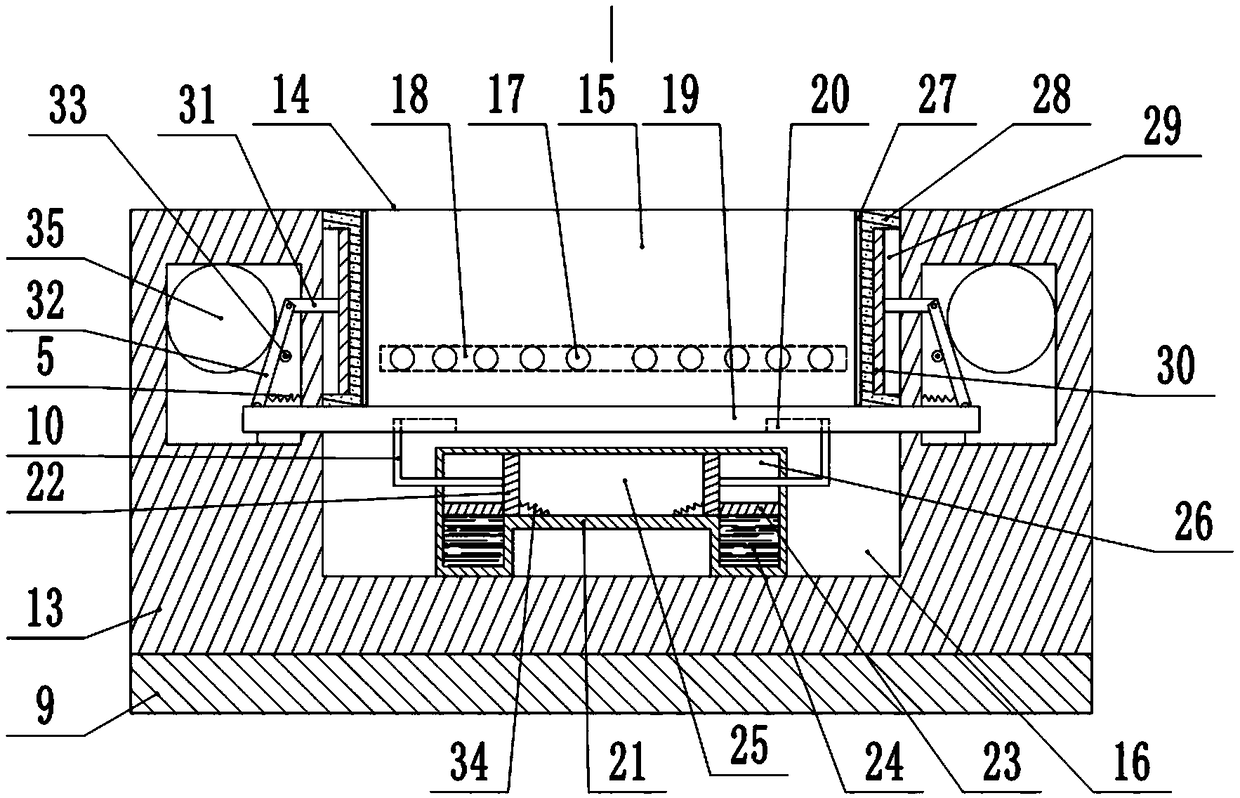

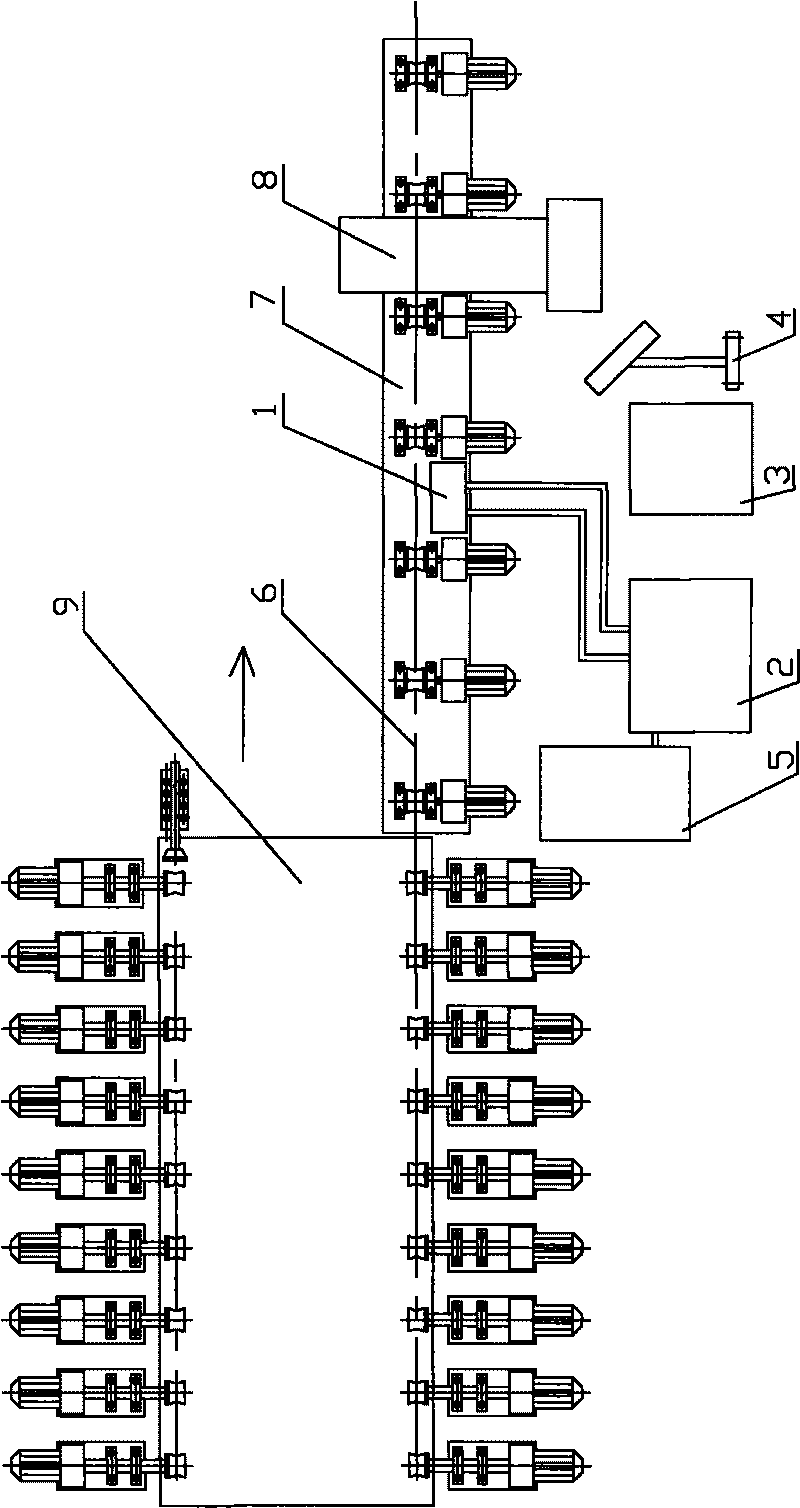

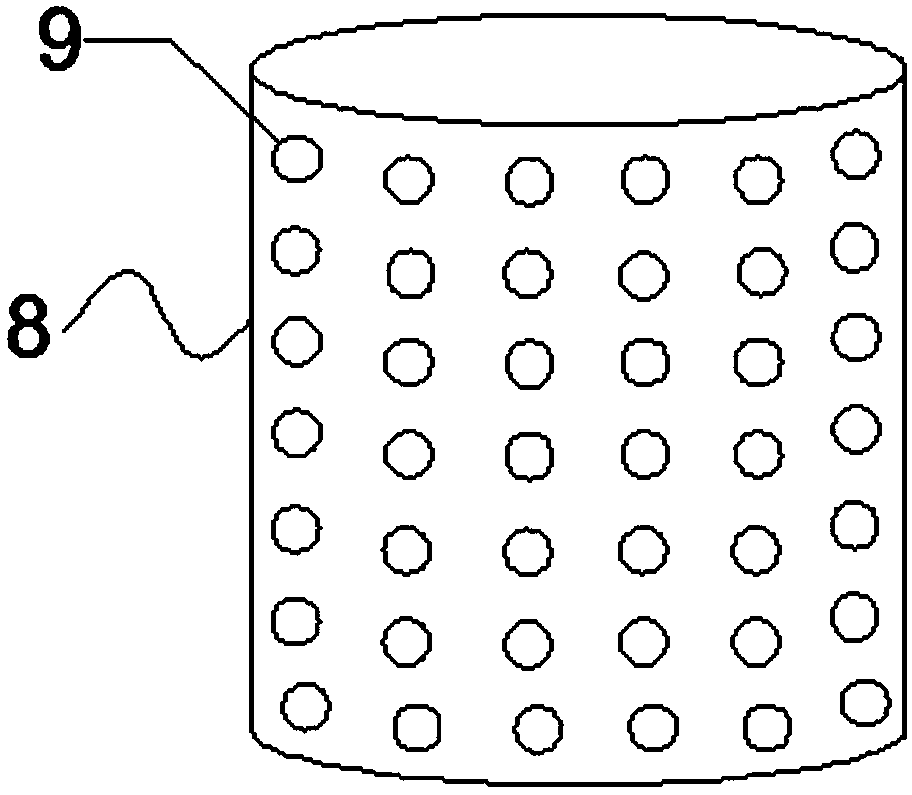

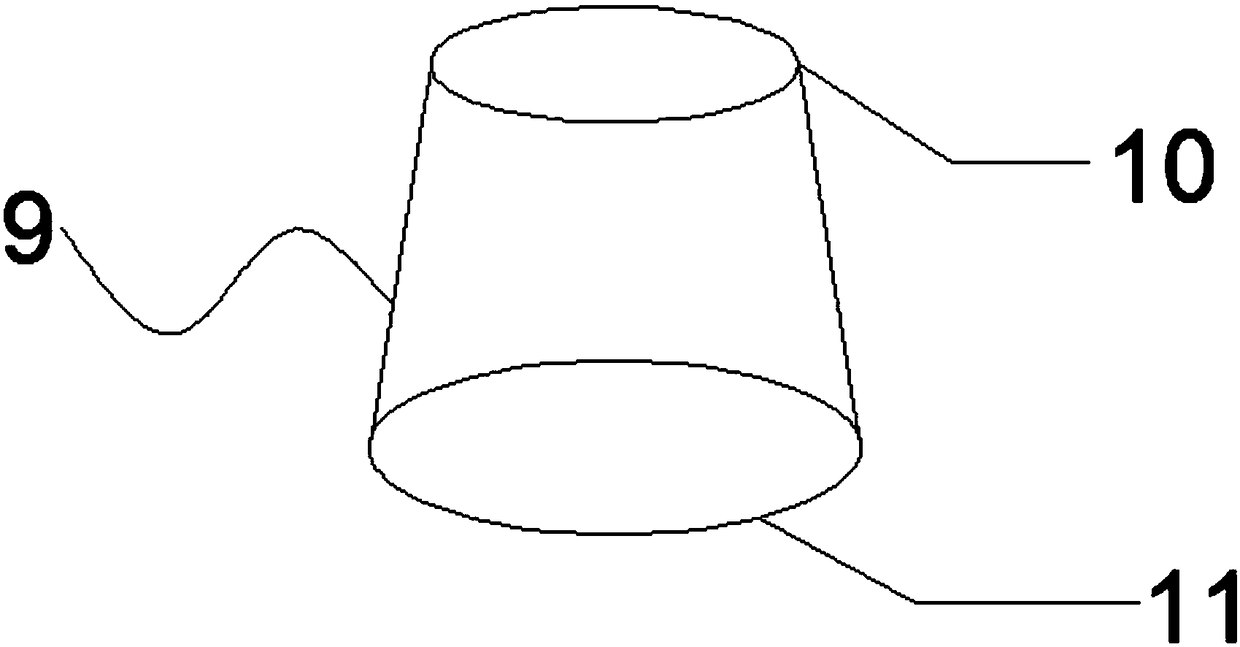

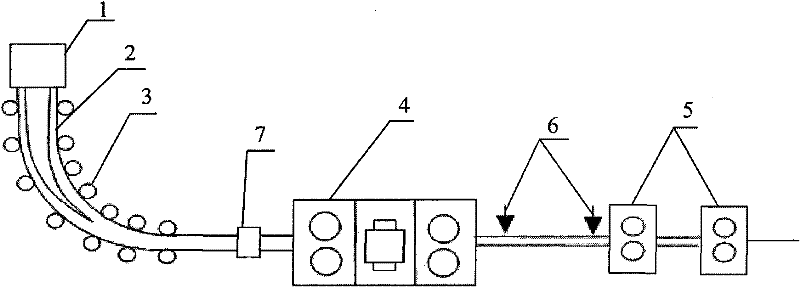

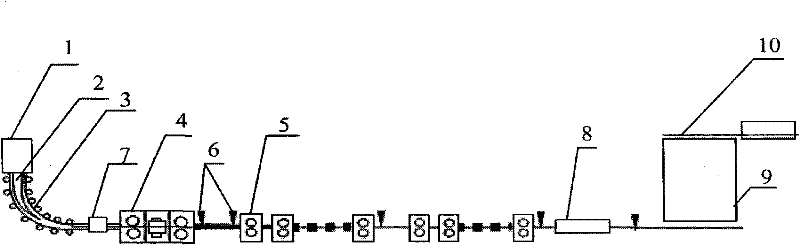

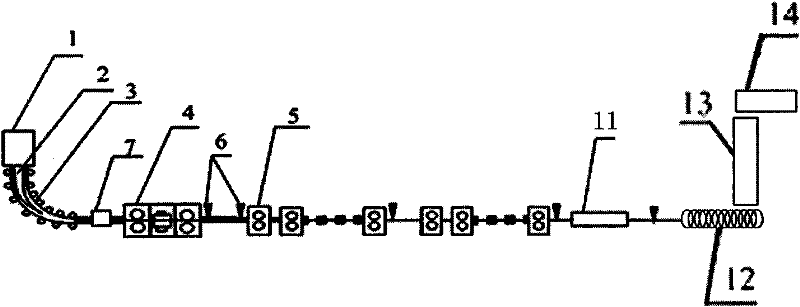

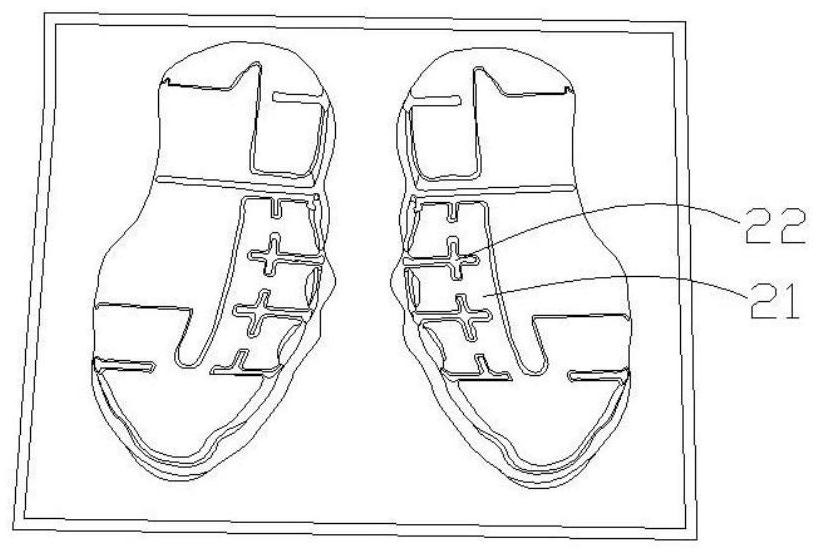

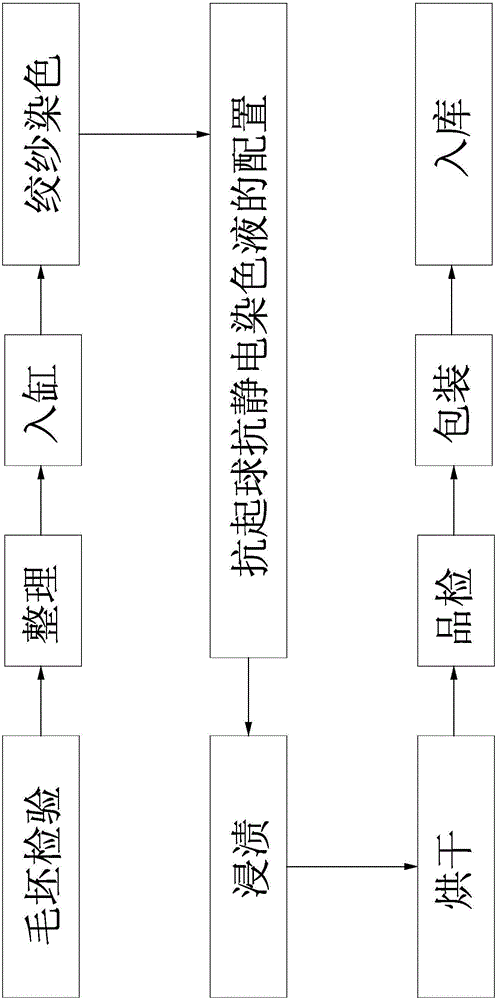

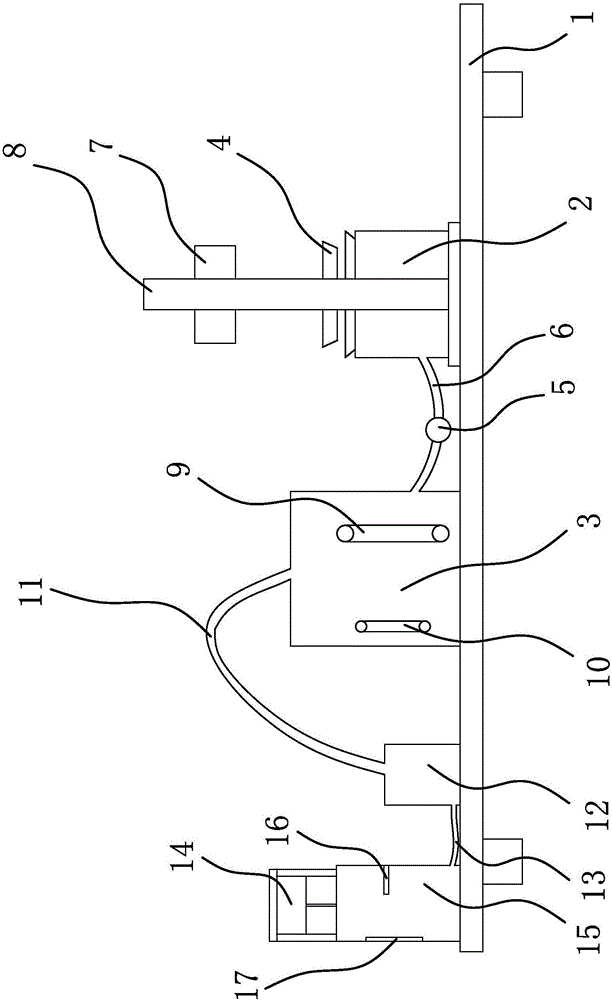

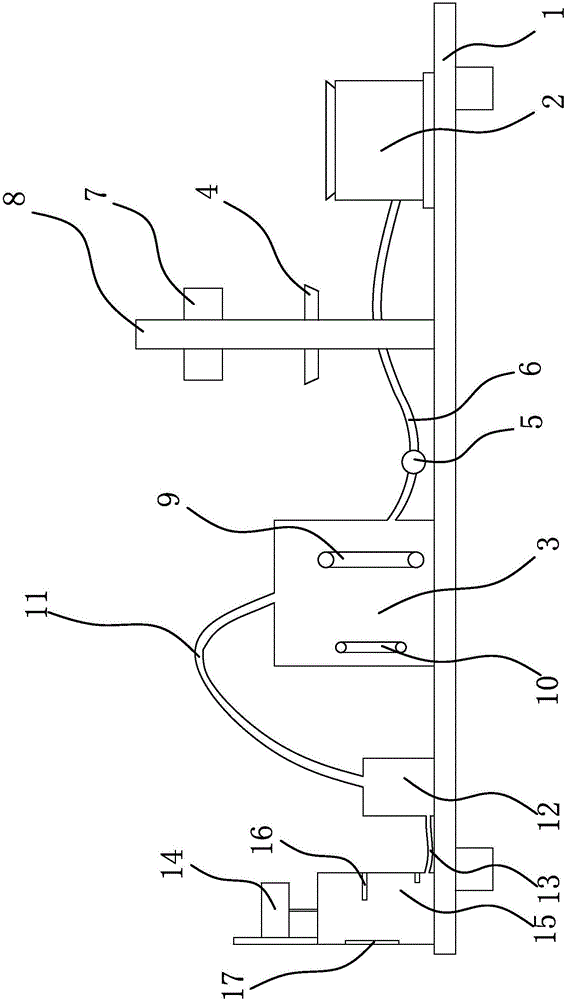

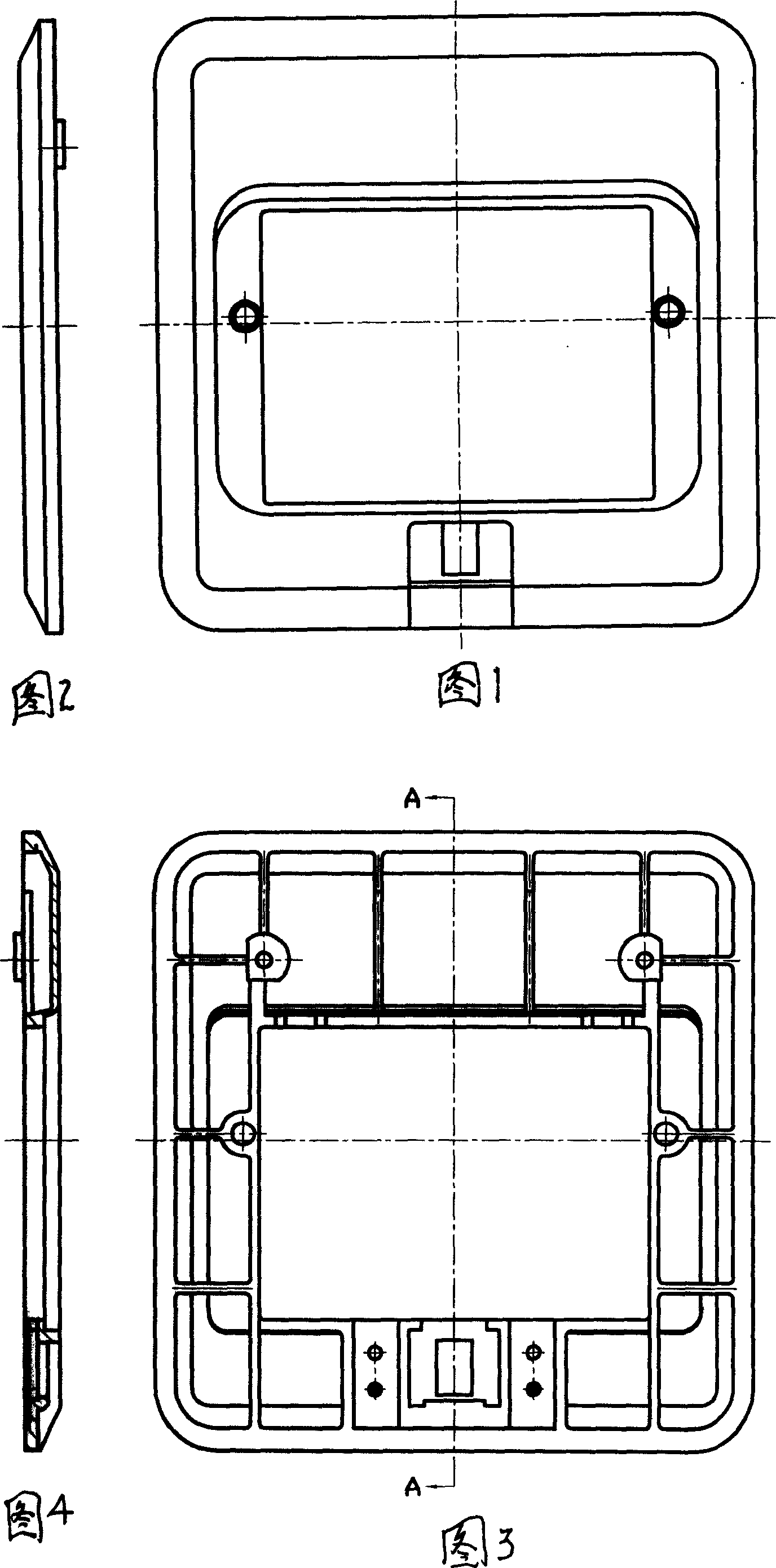

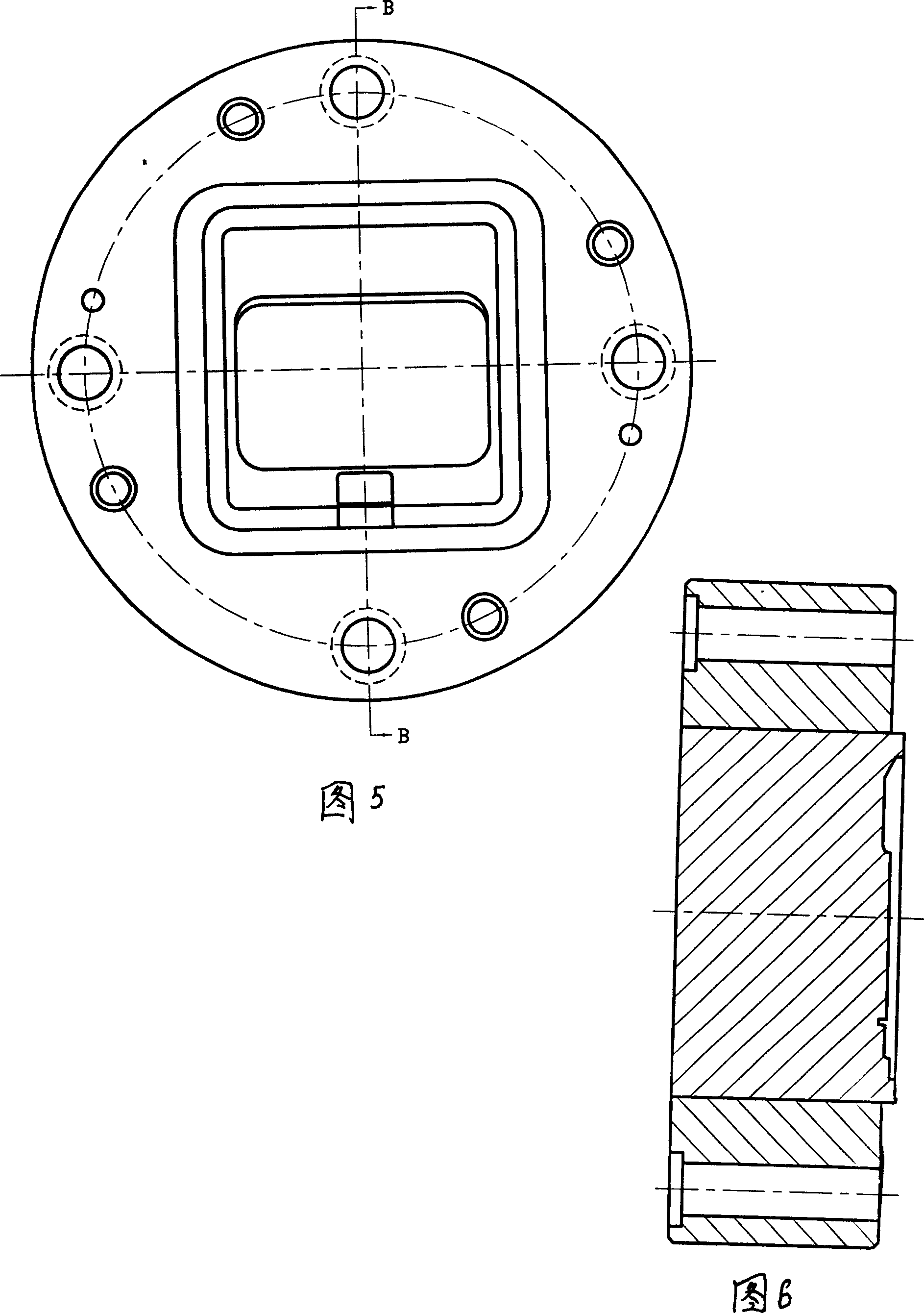

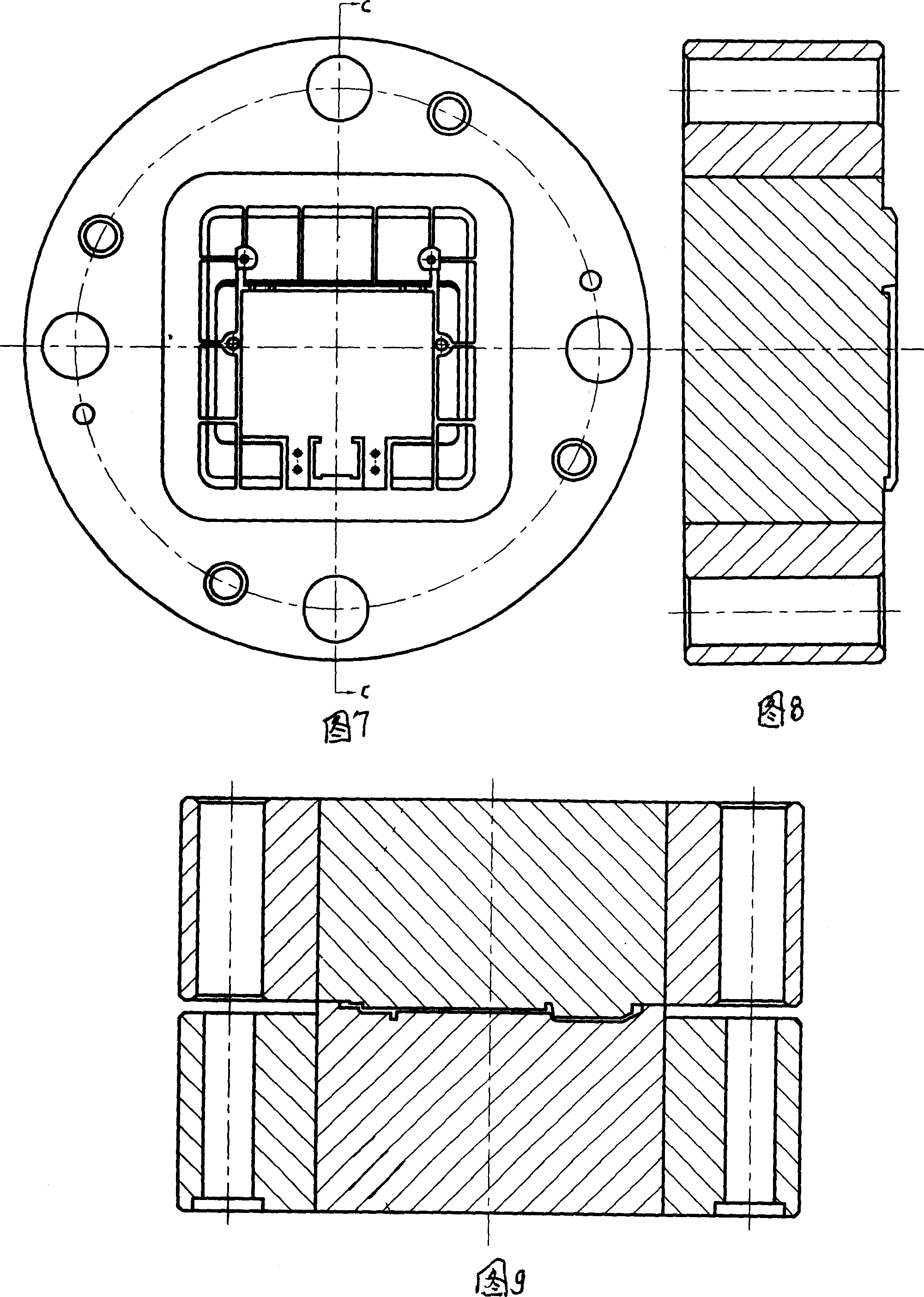

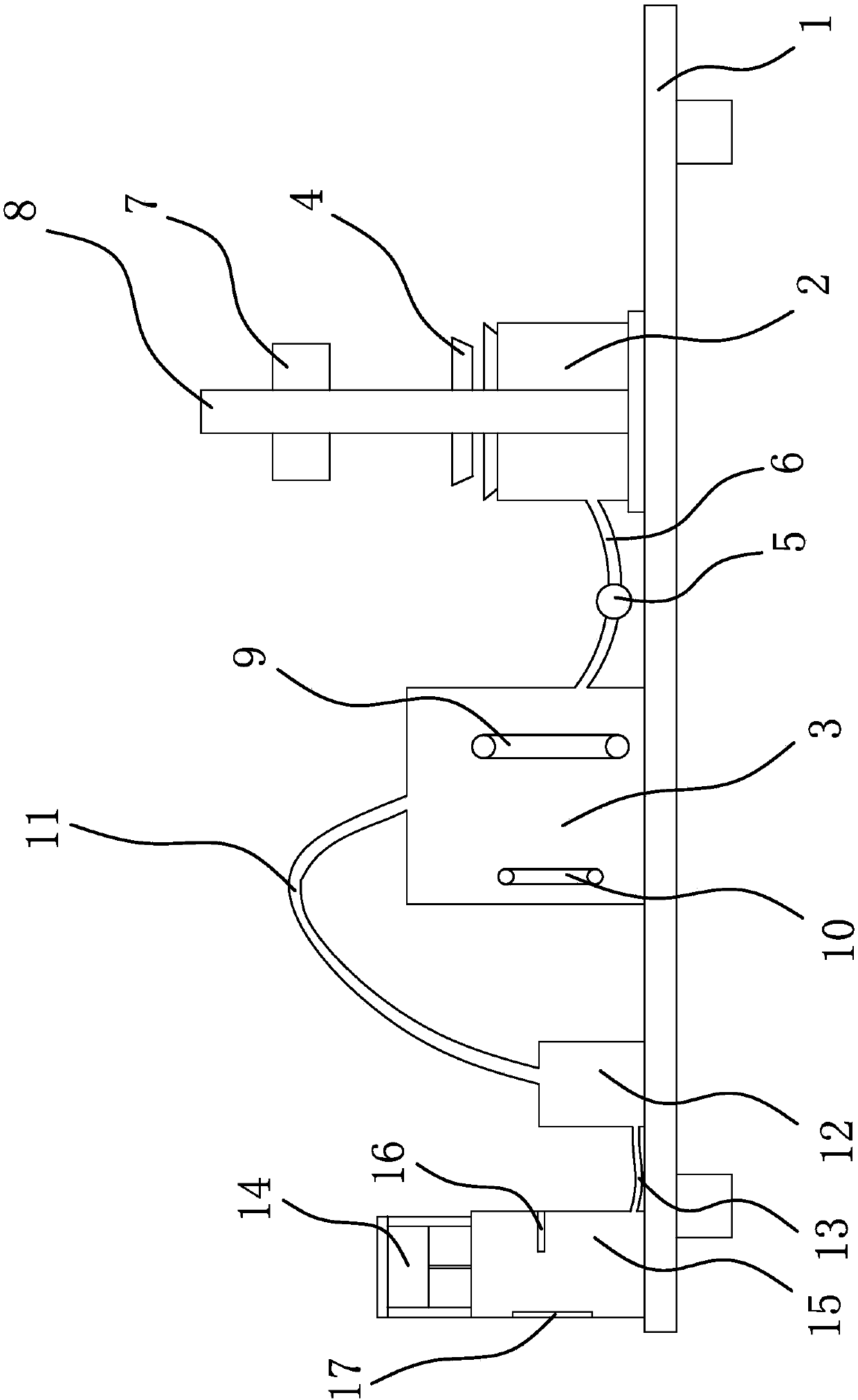

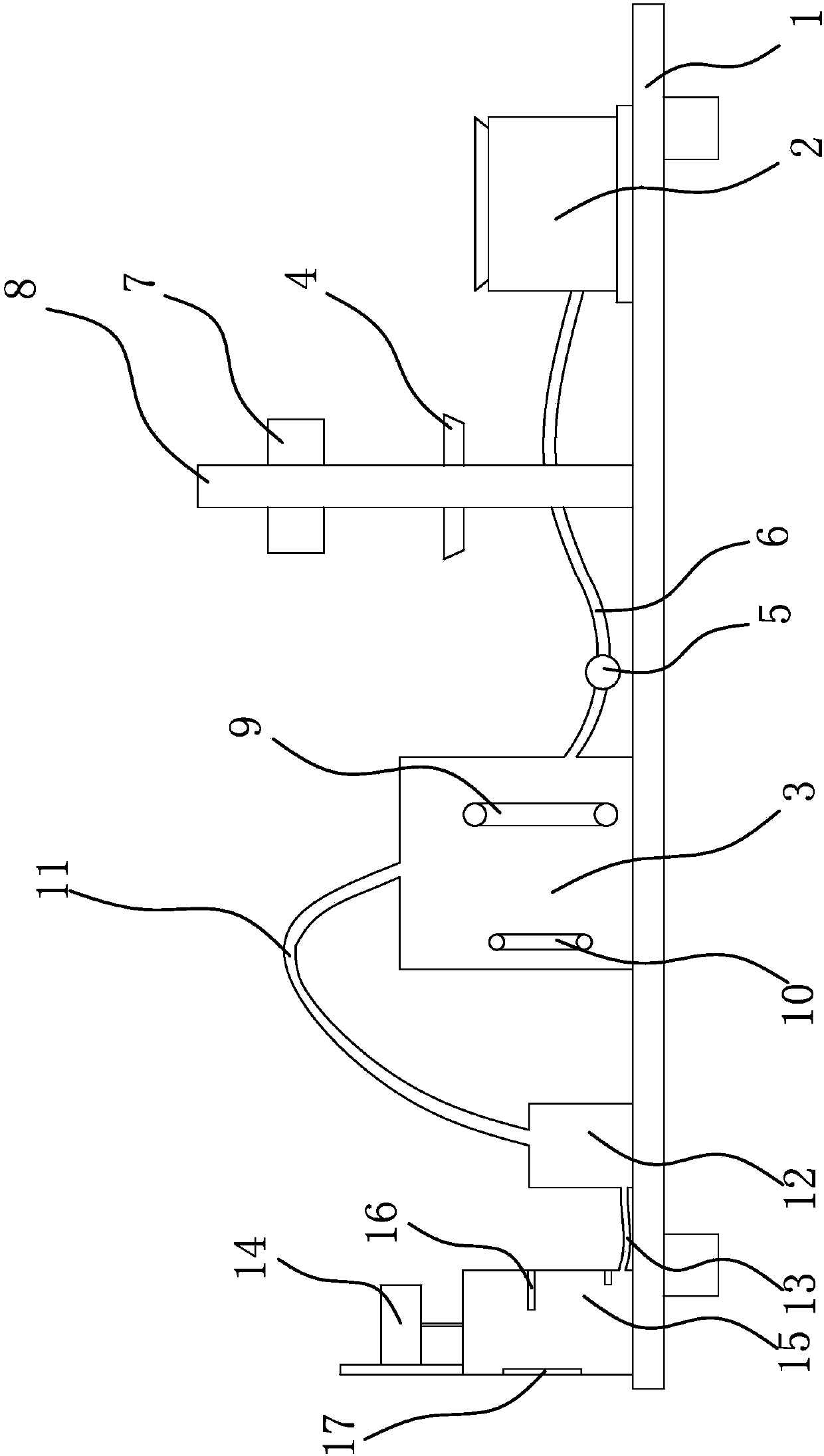

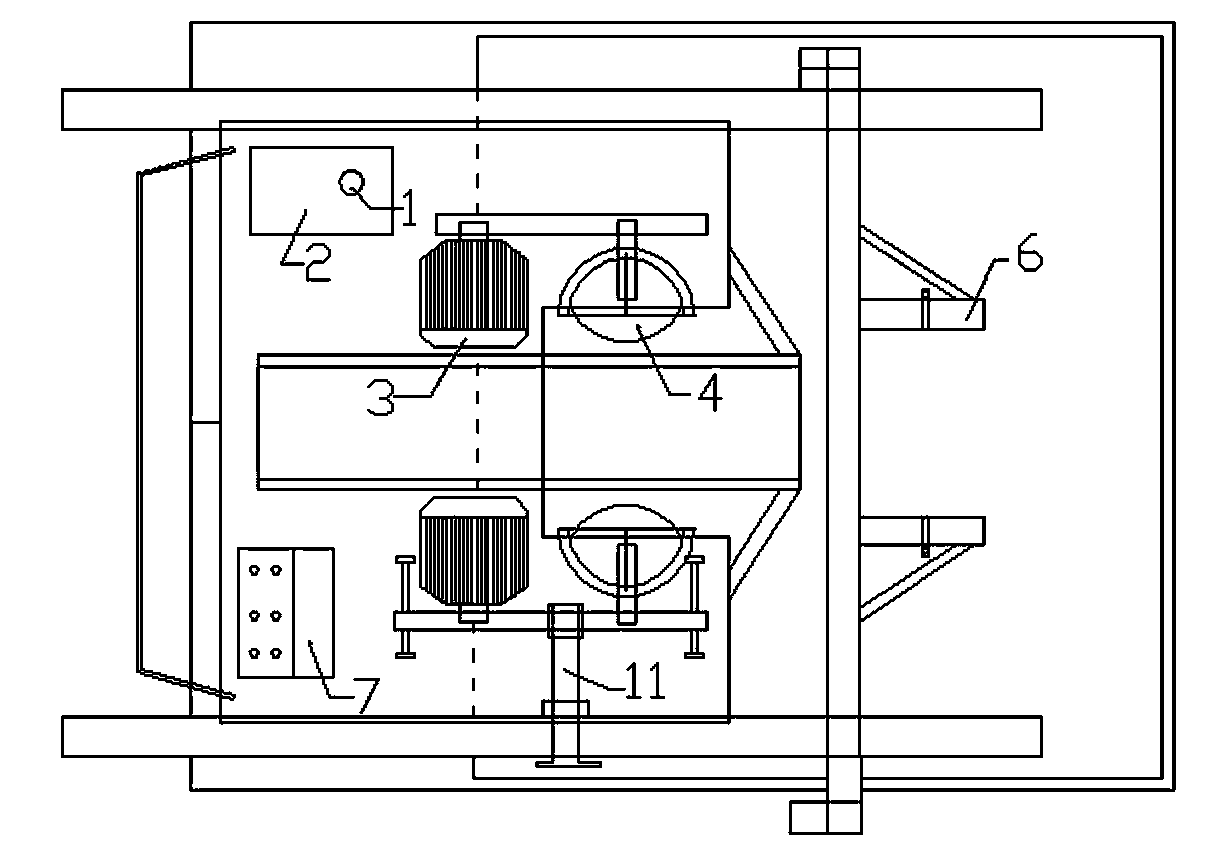

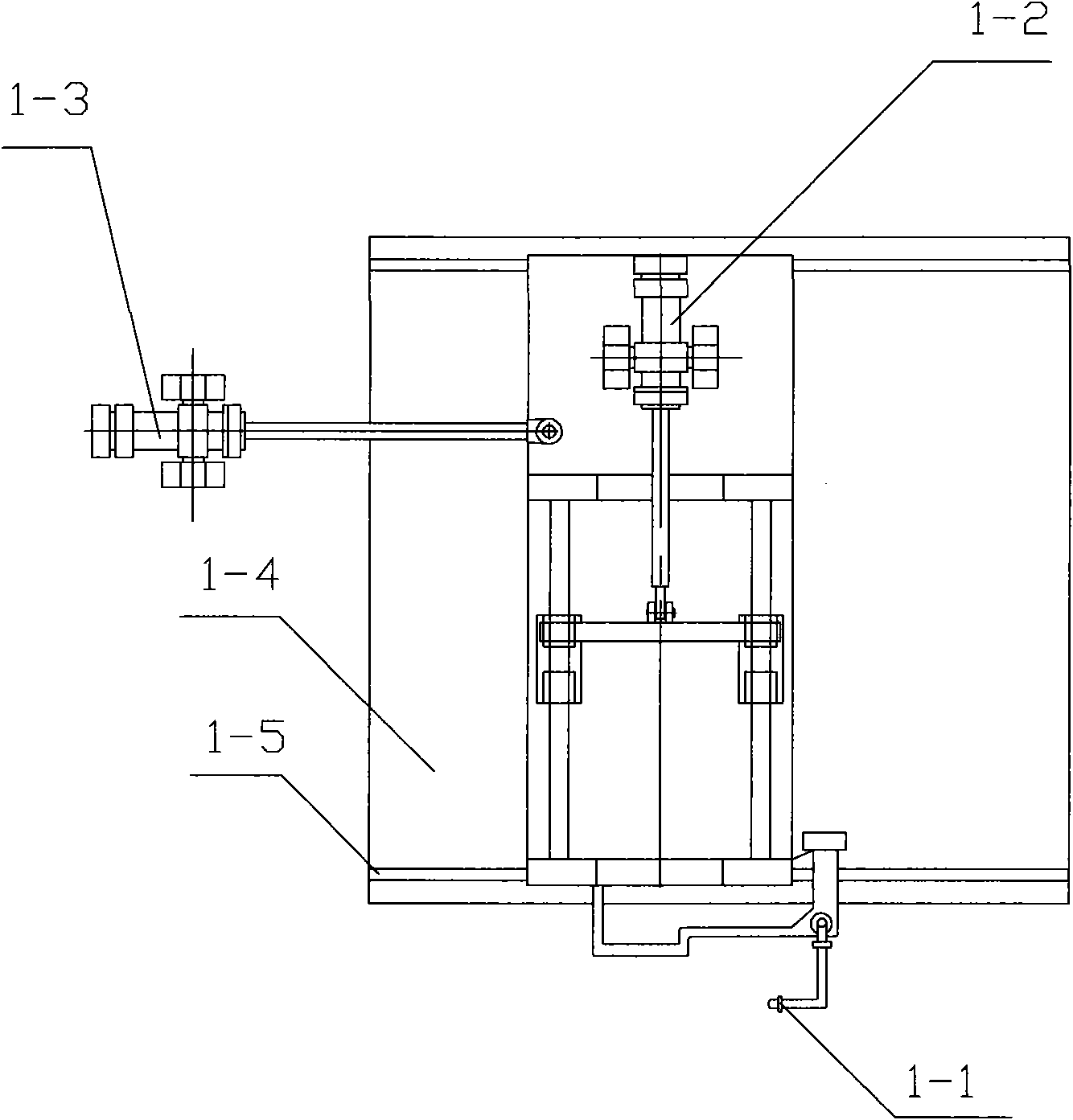

Dyeing and finishing process of antipilling-antistatic yarn and automatic impregnator for dyeing and finishing process

ActiveCN105908417AReduced finishing processLasting effectTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentDyeingYarn

The invention provides a dyeing and finishing process of an antipilling-antistatic yarn and an automatic impregnator for the dyeing and finishing process, belongs to the technical field of textile machinery, and solves the problems of insufficient impregnation of yarns and shortage of the dyeing and finishing process with antipilling and antistatic performance. The dyeing and finishing process for the yarn with waterproof properties comprises the following steps: A, inspecting blanks, B, finishing, C, putting into a vat, D, carrying out hank dyeing; E, preparing an antipilling-antistatic staining solution, F, carrying out impregnation, G, drying, H, inspecting quality, I, packing, and J, putting in storage. The automatic impregnator for the dyeing and finishing process comprises a working table, a hank knotting cylinder is arranged on one side of the working table, a sliding positioning mechanism which can enable the hank knotting cylinder and the working stable to relatively slide is arranged between the hank knotting cylinder and the working stable, an upright column is fixed on the working stable, and a lifting mechanism which can enable a compressing plate to move up and down is arranged between the upright column and the compressing plate. The automatic impregnator disclosed by the invention has the advantages of high dyeing efficiency, sufficient impregnation and the like.

Owner:ZHEJIANG YINGSHANHONG TEXTILE TECH CO LTD

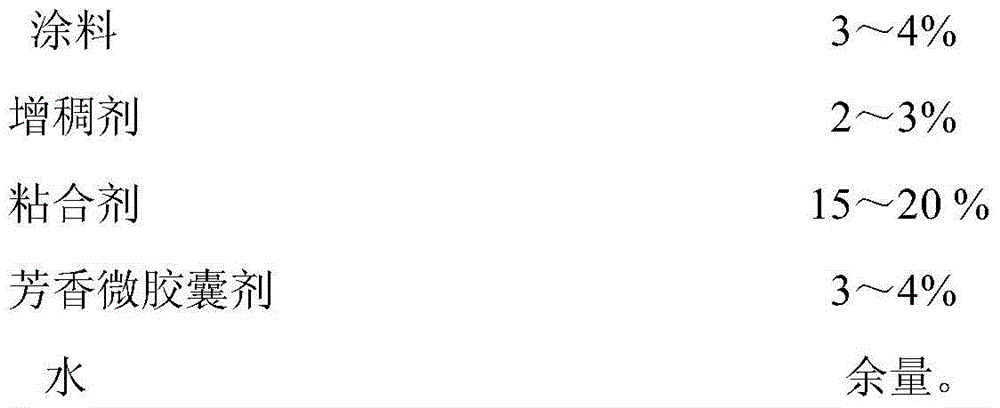

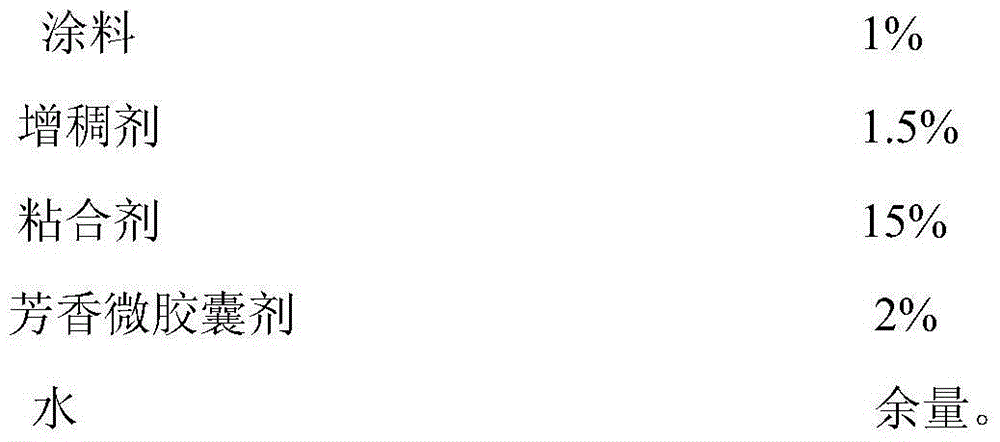

Preparation method of aromatic towel

InactiveCN104894894AEmission reductionLong lasting fragranceFibre treatmentDyeing processScreen printingDrying time

The invention discloses a preparation method of an aromatic towel. The method mainly comprises the processes of color paste preparation, printing, drying, tentering and the like. The printing color paste is prepared from the following components in percentage by weight: 1-5% of pigment, 1.5-3% of thickening agent, 15-20% of binder, 2-5% of aromatic microcapsule and the balance of water. A rotary screen printing machine is used for printing; the drying temperature is within the range of 80-100 DEG C and the drying time is within the range of 3-5 minutes. The preparation method has the advantages of simple process, short process flow, low pollution, low cost and the like; and the aromatic microcapsule is added to the pigment color paste, and consequently, the produced towel product is lasting and pure in aroma.

Owner:JINAN ZHENGQI BIOTECHNOLOGY CO LTD

The making method of the ground jack copper panel and copper up-cover

InactiveCN1996674AReduce pollutionExtended service lifeLine/current collector detailsCouplings bases/casesPunch pressCopper

This invention relates to earth socket copper panel and its copper cover process method, which comprises the following steps: cutting copper bar with name as H58-H60 and diameter as Phi45-Phi60 by proportion into copper blocks with weight 25%-35% more of copper panel or cover and heating the blocks till red; Fixing the forge tool into friction pressure machine with no less than 600 tons; clamping the red copper blocks into forge tool mode for shaping by friction pressure machine; then using impact bed and special mode tool for whole opening, cutting to process copper panel or copper cover to get final product.

Owner:ZHEJIANG JINHAO ELECTRICAL

Dyeing and finishing process of anti-pilling and anti-static yarn and its automatic dipping machine

ActiveCN105908417BReduce finishing processEasy to operateTextile treatment machine arrangementsLiquid/gas/vapor yarns/filaments treatmentYarnStaining

The invention provides a dyeing and finishing process of an antipilling-antistatic yarn and an automatic impregnator for the dyeing and finishing process, belongs to the technical field of textile machinery, and solves the problems of insufficient impregnation of yarns and shortage of the dyeing and finishing process with antipilling and antistatic performance. The dyeing and finishing process for the yarn with waterproof properties comprises the following steps: A, inspecting blanks, B, finishing, C, putting into a vat, D, carrying out hank dyeing; E, preparing an antipilling-antistatic staining solution, F, carrying out impregnation, G, drying, H, inspecting quality, I, packing, and J, putting in storage. The automatic impregnator for the dyeing and finishing process comprises a working table, a hank knotting cylinder is arranged on one side of the working table, a sliding positioning mechanism which can enable the hank knotting cylinder and the working stable to relatively slide is arranged between the hank knotting cylinder and the working stable, an upright column is fixed on the working stable, and a lifting mechanism which can enable a compressing plate to move up and down is arranged between the upright column and the compressing plate. The automatic impregnator disclosed by the invention has the advantages of high dyeing efficiency, sufficient impregnation and the like.

Owner:ZHEJIANG YINGSHANHONG TEXTILE TECH CO LTD

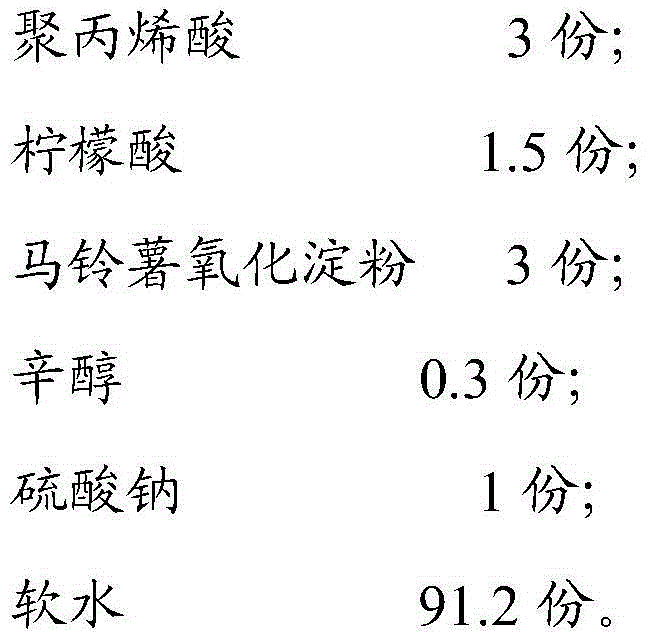

a slurry composition

The invention discloses a sizing agent combination which comprises, by weight, 1-3 parts of thickener, 0.5-1.5 parts of crease-resistant agent, 2-4 parts of potato oxidized starch, 0.2-0.5 part of antifoaming agent, 0.5-1 part of leveling agent and 90-95 parts of water. By means of the synergistic effect of all the constituents, the water retention capacity and viscosity of the sizing agent combination are improved, and the dyeing effect of dye-based ink is good. Fabric subjected to digital printing by means of the sizing agent combination can be colored deeper and brighter, the color design is clear, and stain bleeding is avoided. Due to the adoption of the crease-resistant agent, the crease resistance of silk and wool blended fabric is improved greatly, the finishing process conducted after the silk and wool blended fabric is printed is omitted, and energy is saved. Due to the adoption of the antifoaming agent, even sizing is achieved by means of the sizing agent combination, no foam is generated, and the printing effect is improved.

Owner:佛山市三水嘉骏纺织染有限公司

Method for improving post-welding comprehensive performance of large-diameter thin-wall duplex stainless steel joint

PendingCN113664477AExcellent overall performanceReduced finishing processPlasma welding apparatusThin walledManufacturing engineering

The invention discloses a method for improving post-welding comprehensive performance of a large-diameter thin-wall duplex stainless steel joint, belongs to the technical field of welding, and solves the technical problems that the welding state performance of a large-diameter thin-wall duplex stainless steel pipe is insufficient, and a heat treatment state welded pipe collapses and deforms. The method comprises the following steps that firstly, welding process regulation and control are carried out, in the welding process, welding heat input is strictly controlled according to the characteristics of a dual-phase steel material, and sigma phase precipitation is reduced; and secondly, heat treatment process regulation and control are carried out, the relative content of alpha / gamma phases is regulated and controlled, the harmful sigma phase is eliminated, meanwhile, the stress distribution rule of a welded pipe is calculated and analyzed, an auxiliary device for preventing deformation of the welded pipe in the heat treatment process is assembled in the pipe, the obtained welded pipe has excellent comprehensive performance and does not have obvious collapse deformation, the subsequent finishing procedure is obviously reduced, and the product performance is greatly improved.

Owner:中钢不锈钢管业科技山西有限公司

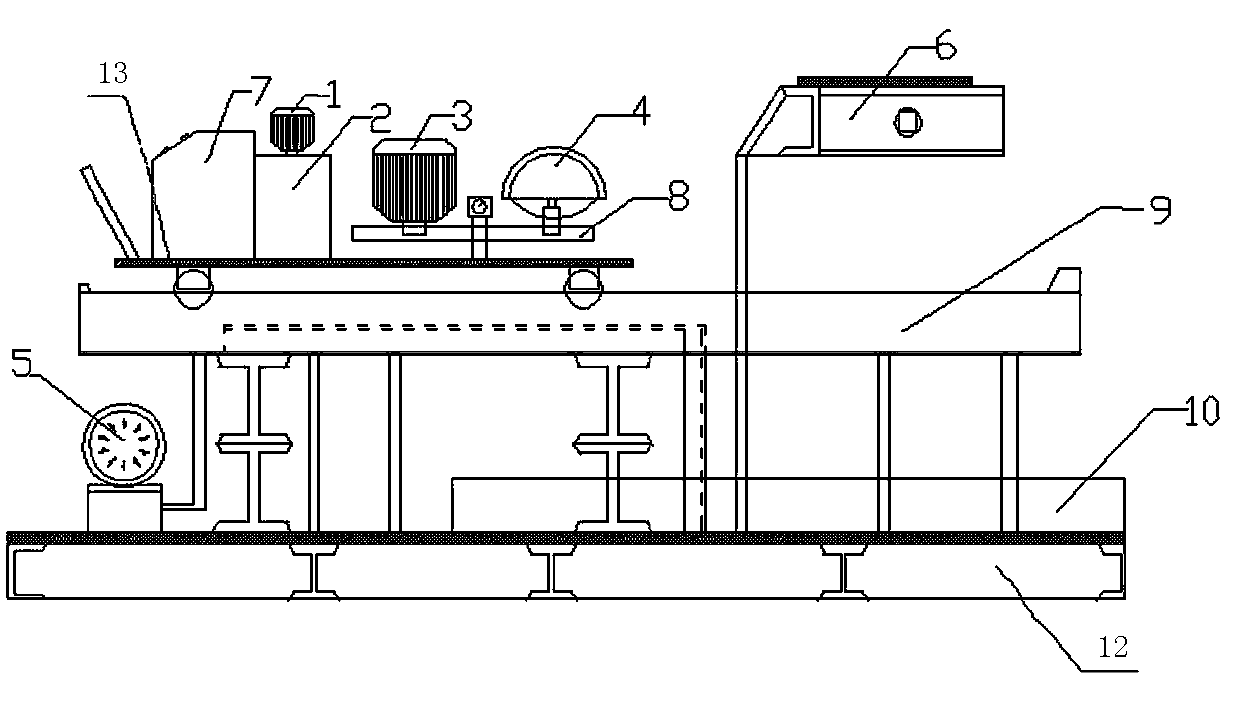

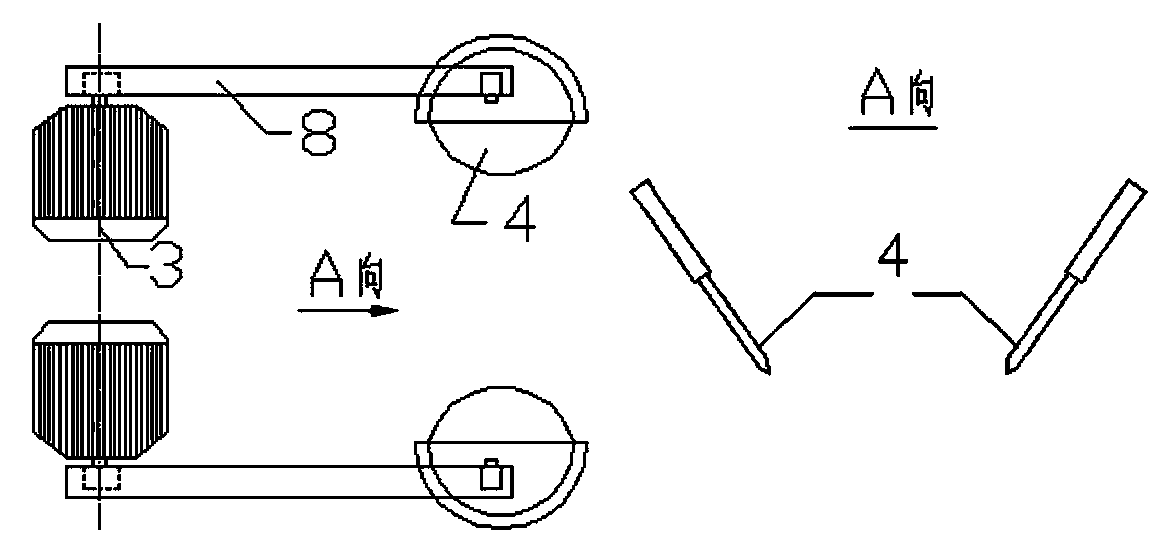

Automatic cutting device for anode rods

ActiveCN102489775BRealize automatic operationReduce labor intensityMetal sawing devicesMetal sawing accessoriesElectric machineMaterial consumption

The invention discloses an automatic cutting device for anode rods, which belongs to the technical field of electrolytic anode processing. The device comprises a base, a rod fixed frame and a traveling rail are fixed on the base, the traveling rail is connected with a movable plate, an electric control box and a cutting system are arranged on the movable plate, the cutting system comprises electric saw motors arranged on both sides of a processing position, each motor is connected with a saw blade by a pulley drive mechanism, and an inclined angle of 45 degrees is formed between each electric saw motor as well as each saw blade and the horizontal plane; and the electric saw motor and the saw blade on one side are integrally arranged on a gap-adjusting sliding plate, and a travelling motor is arranged on the base. By using the device disclosed by the invention, the automatic cutting of anode rods can be realized, the operating efficiency is high, the material consumption is reduced, and the device is safe and reliable.

Owner:徐州大屯工贸实业有限公司

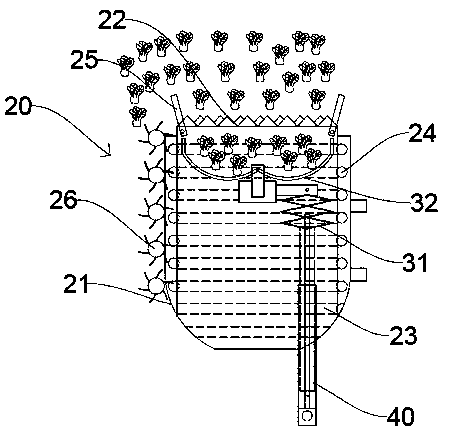

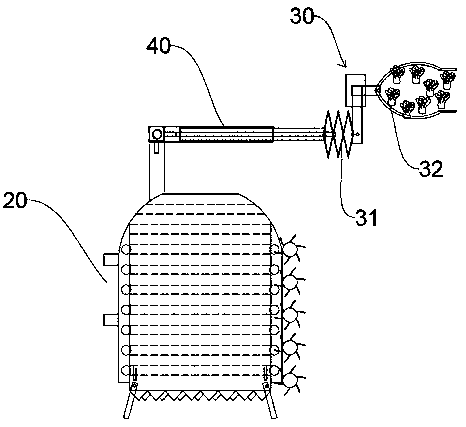

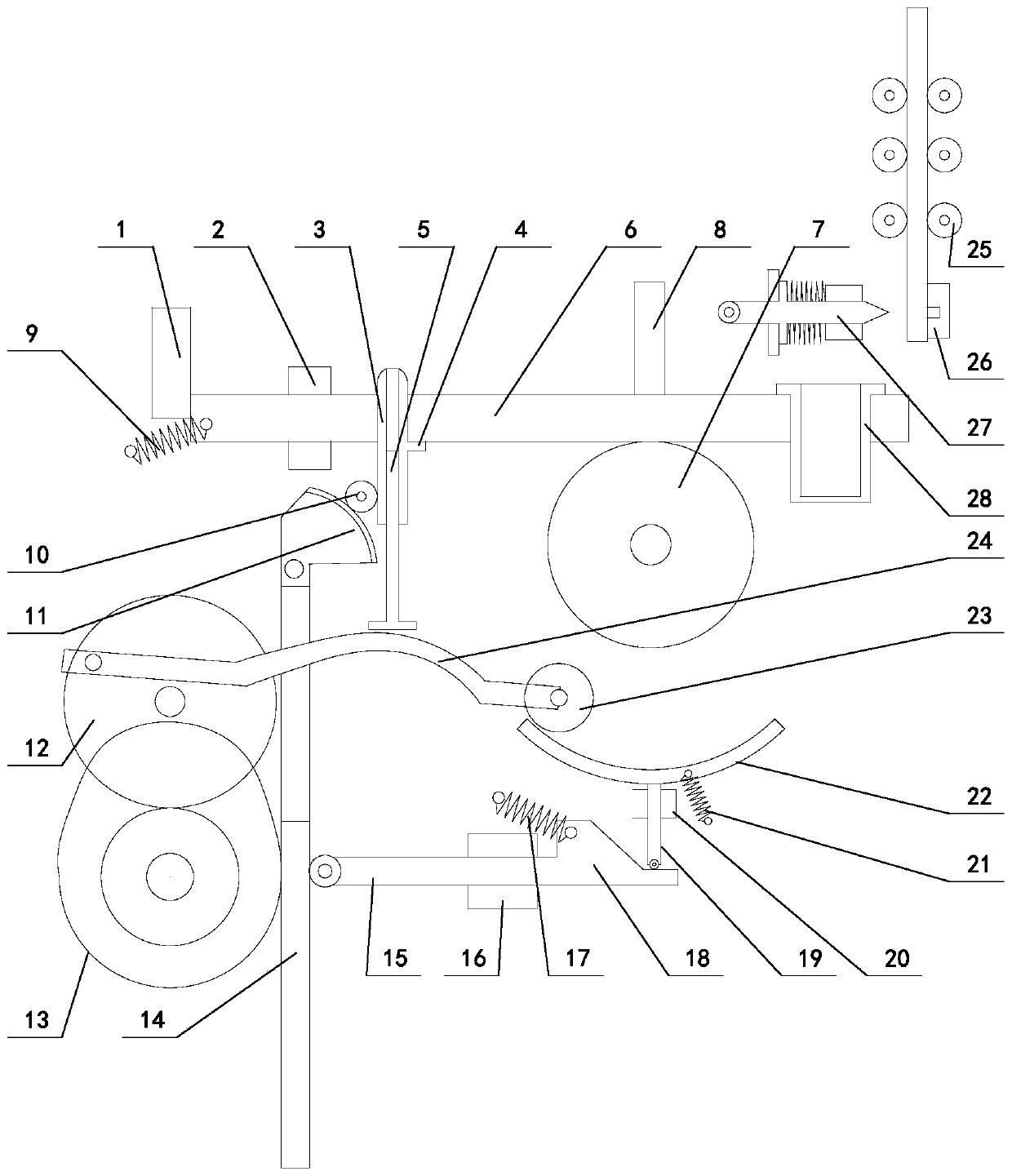

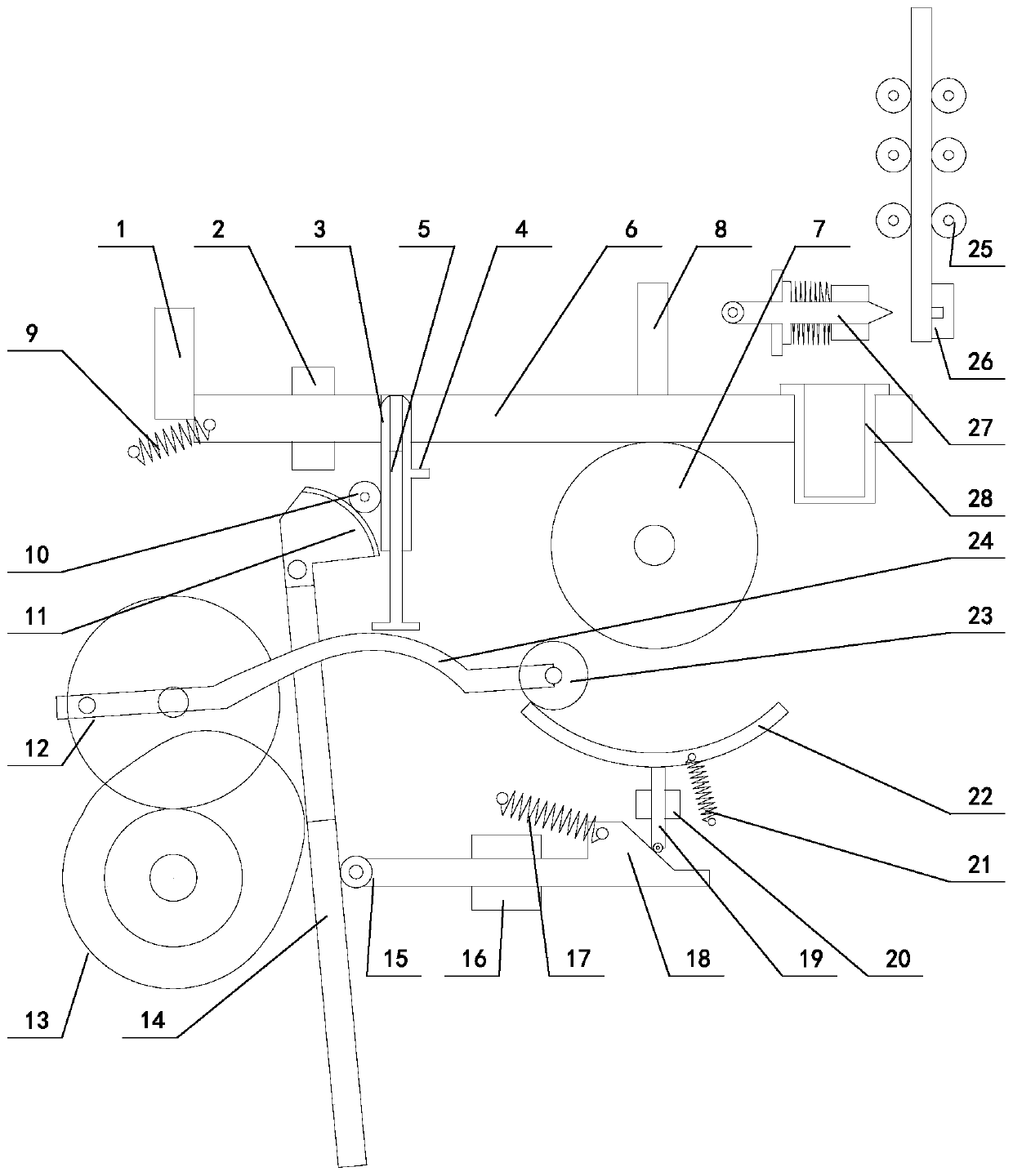

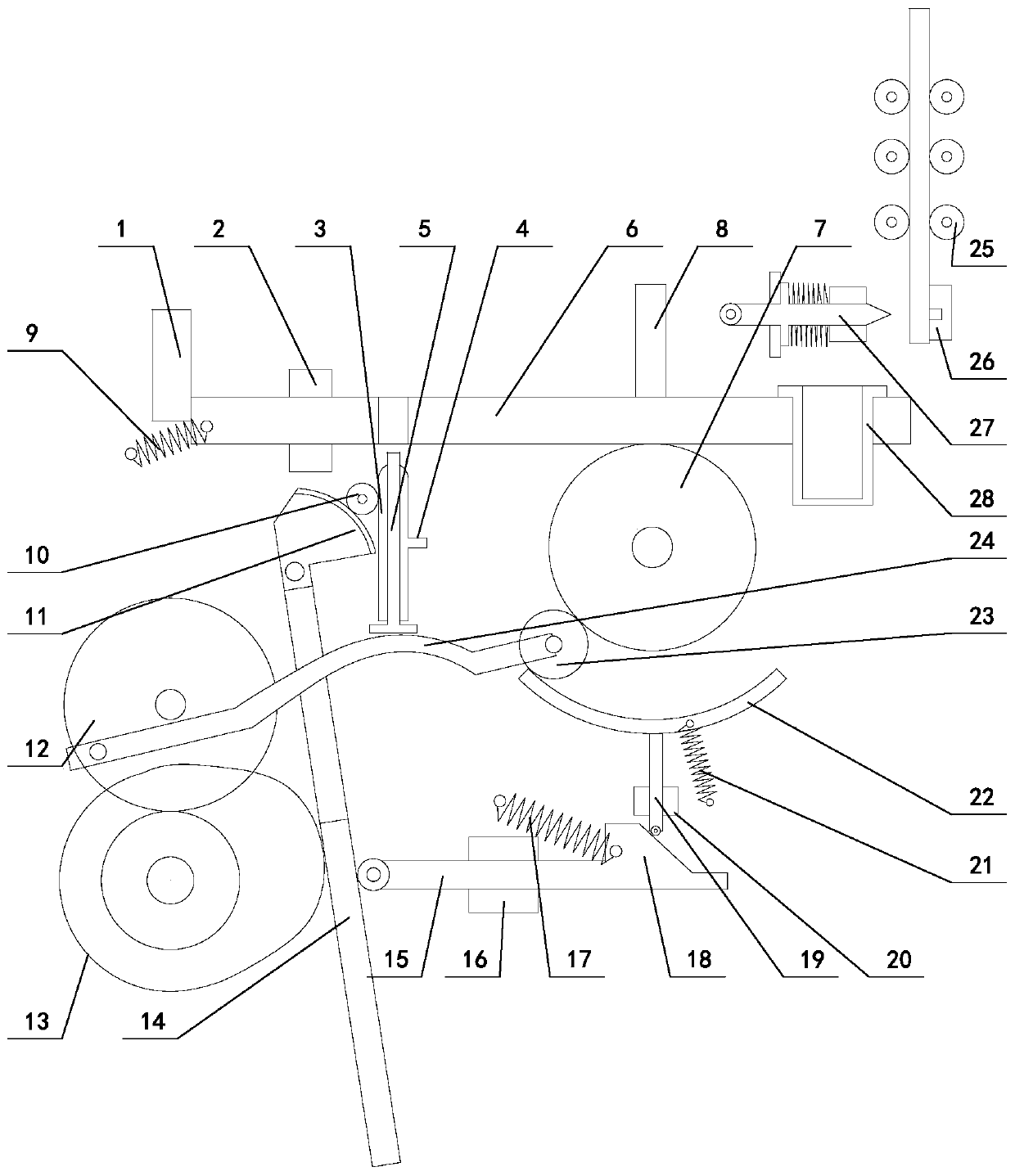

Automatic cutting long strip workpiece equipment

ActiveCN108555975BPrecise control of time accuracyFree laborMetal working apparatusProduction lineEngineering

The invention discloses automatic long striped workpiece cutting equipment. The automatic long striped workpiece cutting equipment comprises a cutting tool mechanism, a swinging rod (14), a cam driving mechanism for driving the swinging rod (14) to swing, a link gear connected with the swinging rod (14) and driving the cutting tool mechanism to reset, a timing limiting mechanism with a limiting function for the cutting tool mechanism, and a feeding mechanism. The feeding mechanism is connected to a machine tool of the equipment and located above the cutting tool mechanism, and the feeding mechanism includes a plurality of feeding roller (25). The multiple feeding rollers (25) are arranged in two rows in the vertical direction. A cutter spacing mechanism corresponding to a cutting knife (27) in the cutting tool mechanism is further arranged on the machine tool of the equipment below the lowermost feeding rollers (25). After adopting the above structure, the labor force can be greatly liberated and the production efficiency can be greatly improved on the one hand, and on the other hand, the production process of an automated production line can be fully matched.

Owner:中山市新力高工具实业有限公司

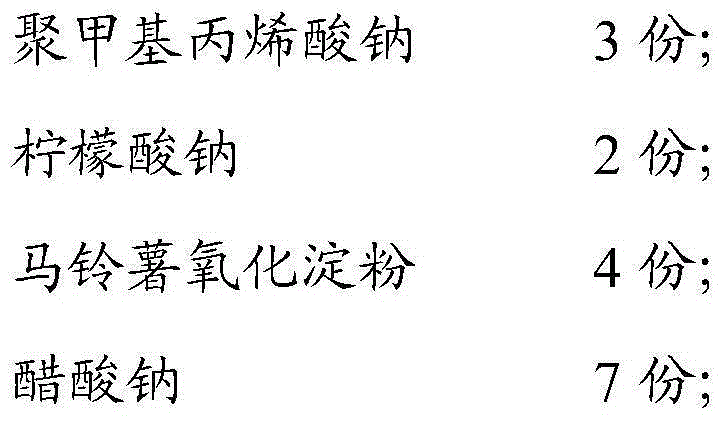

A kind of digital printing paste

InactiveCN104141250BImprove water retentionIncrease viscosityDyeing processPulp and paper industryDigital printing

The invention discloses digital printing paste which comprises the following components, by weight: 1-3 parts of thickeners, 1-2 parts of anti-wrinkling agents, 2-4 parts of potato oxidized starch, 4-7 parts of hygroscopic agents and 84-92 parts of water. The components of the digital printing paste have mutually synergistic effect, so that water-retaining property and viscosity of the digital printing paste are improved, and dyeing effect of dye-based ink is good. Fabrics subjected to digital printing through the digital printing paste have deeper and brighter colors and clear design, and no color penetration happens. By means of the anti-wrinkling agents, anti-wrinkling performance of silk cotton blended fabrics is improved greatly, a finishing procedure after printing of the silk cotton blended fabrics is omitted, and energy is saved. Pollution to the environment caused by the waste produced in the process of the digital printing paste is greatly reduced. The digital printing paste is fewer in components and convenient to prepare.

Owner:SUZHOU INST OF TRADE & COMMERCE

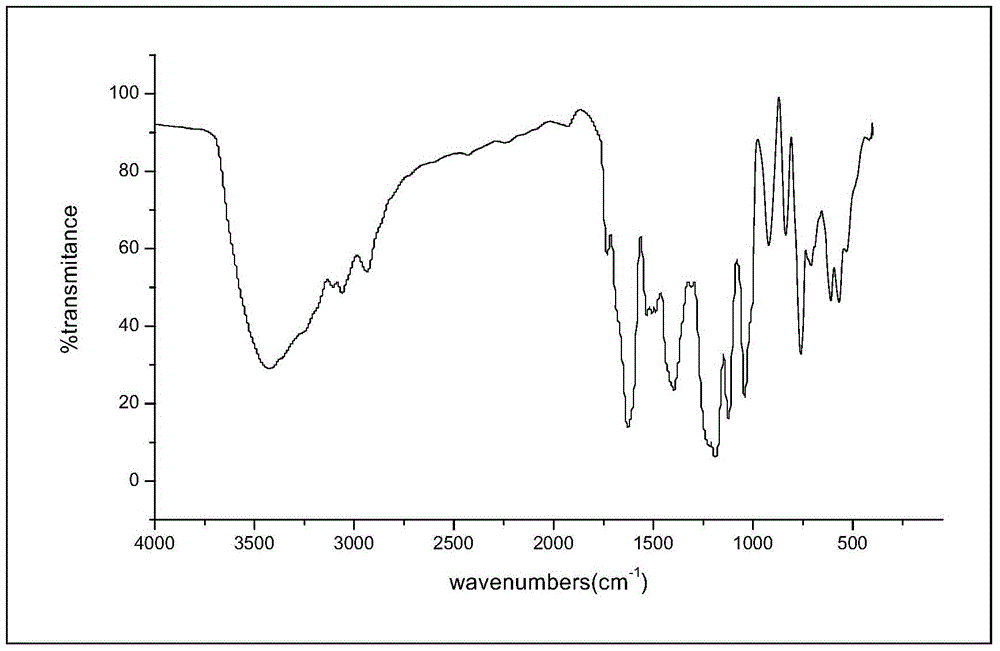

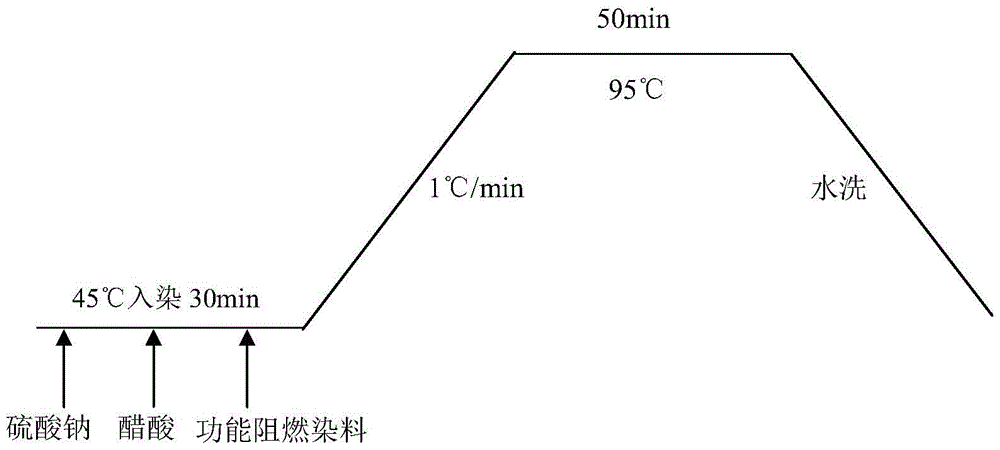

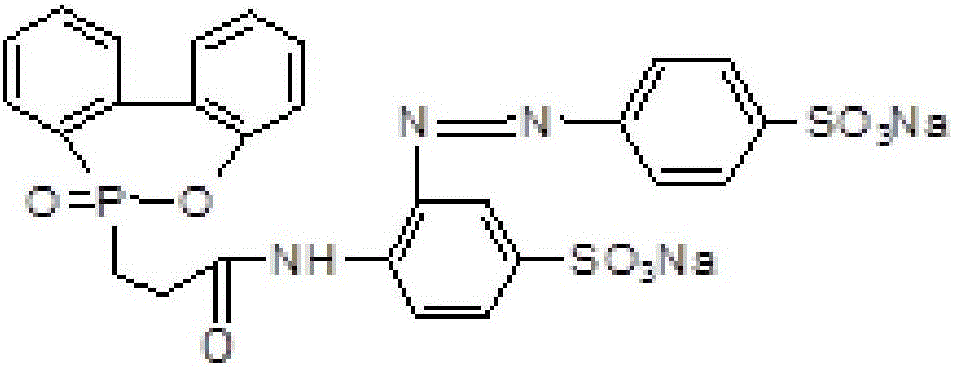

Preparation method and application of flame retardant dye

ActiveCN104830092BDoes not affect the feelLow costAzo dye preparationGroup 5/15 element organic compoundsResource savingDouble bond

The present invention relates to the field of fine chemistry industry, particularly relates to a preparation method and applications of a fire retardation dye. The preparation steps comprise: (1) carrying out an acylation reaction on an acylation reagent containing a carbon-carbon double bond and an azo dye containing amino or hydroxyl so as to introduce the carbon-carbon double bond on the acylation reagent into the azo dye; and (2) carrying out an addition reaction on the carbon-carbon double bond on the azo dye obtained from the reaction and 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide so as to introduce the phosphaphenanthrene group into the azo dye. The prepared fire retardation dye of the present invention has characteristics of dyeing, fire retardation, operation step saving, resource saving, and energy source consumption saving.

Owner:苏州田园纺织科技有限公司

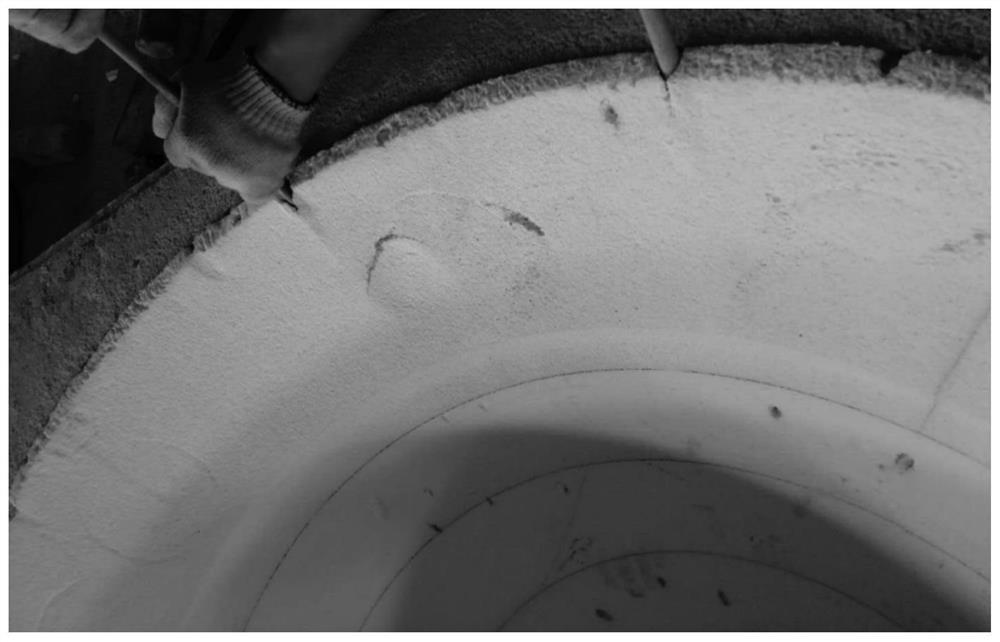

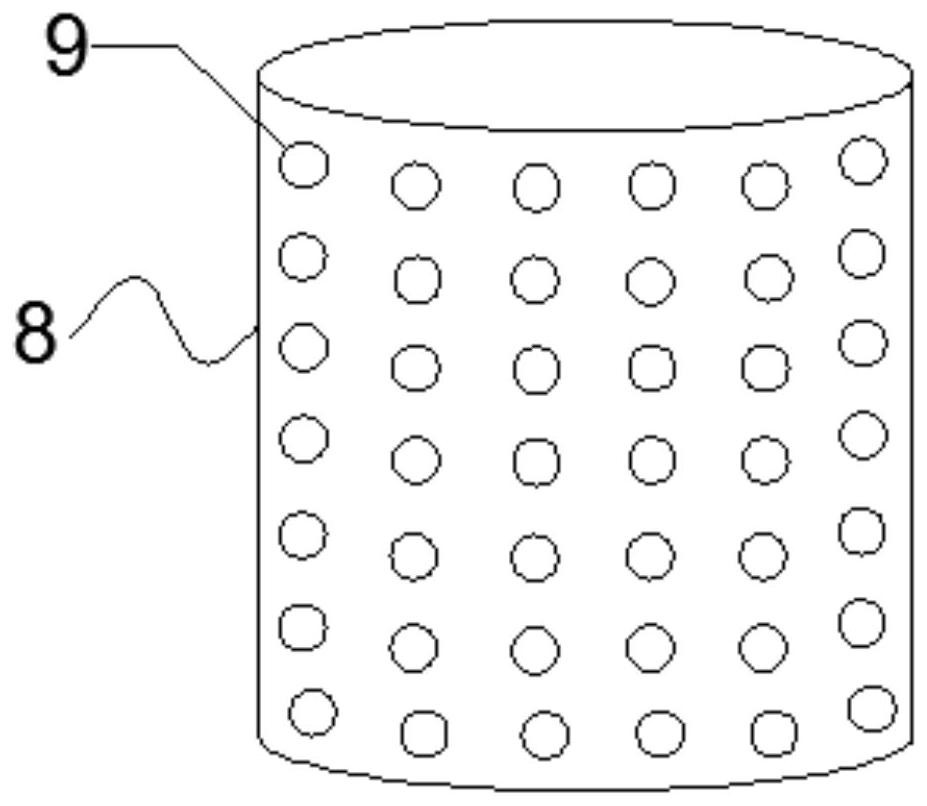

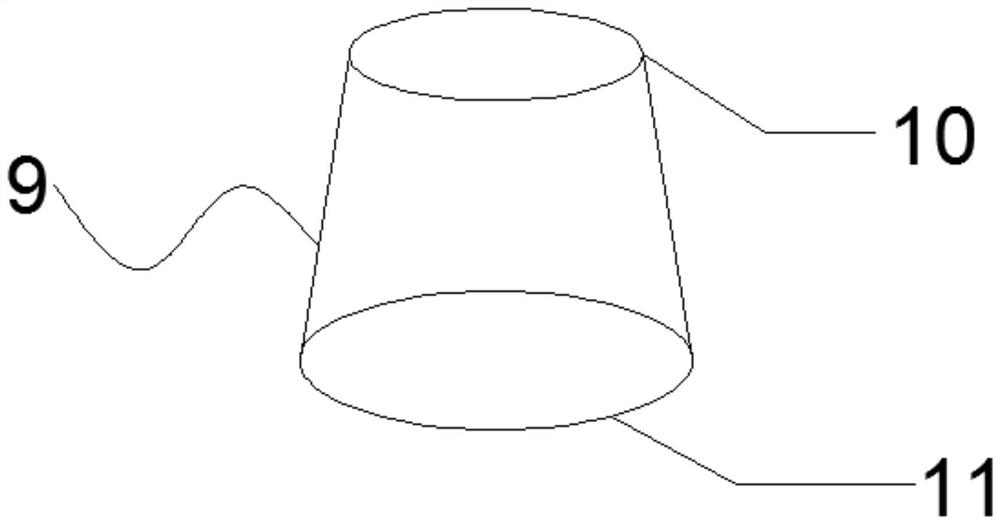

Drawing method of EPS foam-epoxy resin composite die applied to sand casting

PendingCN112111130AHigh strengthSolve the deformation,Non-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAdhesive cement

The invention discloses a drawing method of an EPS foam-epoxy resin composite mold applied to sand mold casting. The drawing method comprises the following steps: S1, preparing an epoxy resin plate material with the thickness being 1-5mm; S2, manually splicing EPS foam plates to form a model with the maximum size required by the mold, and integrally feeding the model into an engraving machine forprocessing to obtain a mold sample; S3, cutting, polishing and sanding the epoxy resin plates according to the specific shape and size requirements of the parting surface of the mold sample to obtainepoxy resin reinforcing plates, and attaching the epoxy resin reinforcing plates to the drawing part of the mold by using an adhesive; and S4, during mold drawing, fixing the mold to a molding flat plate through vacuum adsorption equipment, jacking up a sand box and the sand mold through synchronous hydraulic equipment, so as to complete the mold drawing procedure. The epoxy resin reinforcing plate is additionally arranged on the molded surface of the EPS foam mold, mold drawing can be balanced, the stress point can be reinforced, the overall strength of the mold is improved, and the problemsthat the mold is prone to deformation and difficult to draw in the mold process are solved.

Owner:广西长城机械股份有限公司

A kind of anti-ultraviolet and moisture-absorbing quick-drying yarn and its production process and application

ActiveCN109112688BIncreased durabilityReduce finishing processYarnMonocomponent polyesters artificial filamentYarnFiber

Owner:ZHEJIANG LANTIANHAI FAB TECHNOLAGY CO LTD

A sheet automatic shearing machine

ActiveCN106180351BRealize automatic punchingImprove product qualityMetal-working feeding devicesMetal working apparatusPunchingLinkage concept

The invention discloses an automatic sheet shearing machine; an upper drive feeding roller and an upper driven feeding roller are mounted above a workbench; a lower drive feeding roller and a lower driven feeding roller are mounted below the workbench; the upper drive feeding roller is driven by a feeding motor; the upper drive feeding roller and the lower drive feeding roller are in synchronous transmission connection; a punch mounting base is mounted behind the workbench; a punch is arranged in the punch mounting base in a sleeved manner; under the action of a power device, the punch can horizontally move back and forth; a convex mould is mounted at the front end of the punch; a concave mould matched with the convex mould is arranged at the front end of the convex mould; the concave mould is mounted on the workbench; a magnetic sheet product collecting channel is arranged at the rear end of a cavity structure; a rack is mounted at the side of the convex mould through a linkage plate; and the rack is engaged with a one-way gear at the outer end of the upper drive feeding roller. The automatic sheet shearing machine is applied, so that automatic punching of soft magnetic sheets can be realized, and therefore, magnetic sheet products obtained by punching are automatically ordered.

Owner:宜宾金原复合材料有限公司

A double-sided welding method and double-sided welded product

ActiveCN110153531BReduce temperature differenceAvoid deformationWelding accessoriesIndustrial engineeringManufacturing engineering

The invention provides a double-sided welding method and a double-sided welding product, the method is used for welding a first workpiece and a second workpiece, wherein the first workpiece has a first end, and the second workpiece has a second end , the first end and the second end are adjacent, the first workpiece, the second workpiece, the first end and the second end define a first side and a second side in space; the The method includes: welding the first end and the second end from the first side to form a first weld; welding the first end to the second end from the second side to form a joint with the second end. The first weld seam has a second weld seam that overlaps in depth. The invention can improve welding quality and reduce welding cost.

Owner:SHANGHAI HITACHI ELECTRICAL APPLIANCES CO LTD

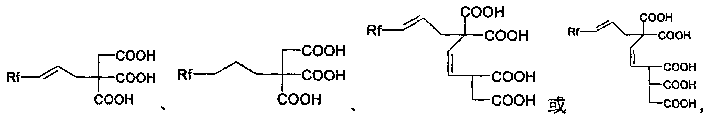

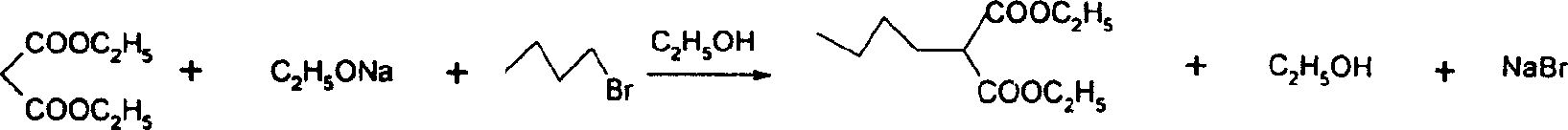

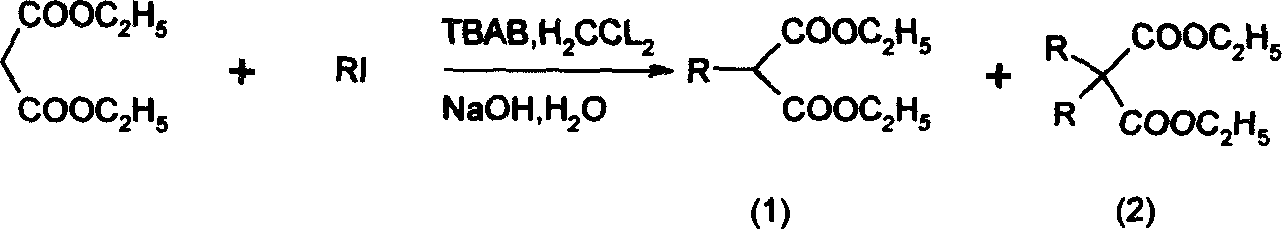

Fluorine-contained polybasic carboxylic acid compound synthesis method and use thereof

InactiveCN1207261CMild reaction conditionsSimple and fast operationOrganic chemistryFibre treatmentPolymer scienceCarboxylic acid

The present invention relates to a kind of fluorine-containing polycarboxylic acid compound and its use. Its structural formula is as follows: ∴ or ∴ wherein: Rf- represents 2-12 carbon polyfluorinated or perfluorinated compounds including saturated and unsaturated carbon chains. carbon chain. It is a dyeing and finishing auxiliary with anti-wrinkle, waterproof and oil-proof properties.

Owner:DONGHUA UNIV

Method and device for removing inner surface oxidized iron sheet of steel pipe on line

ActiveCN101700532BReduce finishing processLow costWork treatment devicesMetal rolling arrangementsSlagHigh pressure water

The invention relates to a method and a device for removing an inner surface oxidized iron sheet of a steel pipe on line. A device for removing an inner surface oxidized iron sheet of a steel pipe from the tail of the steel pipe is arranged behind a stepping type reheating furnace, and the inlet section of a stepping type cooling bed is provided with a device for removing the inner surface oxidized iron sheet of the steel pipe from the head of the steel pipe. After the tail and the head of the steel pipe are detected by a hot metal detector, the device for removing the inner surface oxidized iron sheet of the steel pipe from the tail of the steel pipe sprays high-pressure water to an inner hole of the tail of the steel pipe and removes the oxidized iron sheet of the inner hole of the steel pipe, and the device for removing the inner surface oxidized iron sheet of the steel pipe from the head of the steel pipe sprays high-pressure water and a high-pressure gas to the inner hole of the head of the steel pipe so as to remove oxidized slag retained in the inner hole of the steel pipe. The inner surface oxidized iron sheet of the steel pipe is removed on line behind the stepping type reheating furnace and at the inlet section of the stepping type cooling bed, and the finishing procedure of the rear part of the steel pipe is reduced. The invention not only saves the cost of acid washing, shot blasting and grinding but also improves the production efficiency.

Owner:HENGYANG VALIN STEEL TUBE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com