Automatic cutting device for anode rods

An automatic cutting and anode guide rod technology, applied in metal sawing equipment, metal processing equipment, sawing machine devices, etc., can solve the problems of the guide rod being easily tilted and smashing people, high labor intensity, long working hours, etc., to reduce labor Strength and production cost, improve safety and stability, and save production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

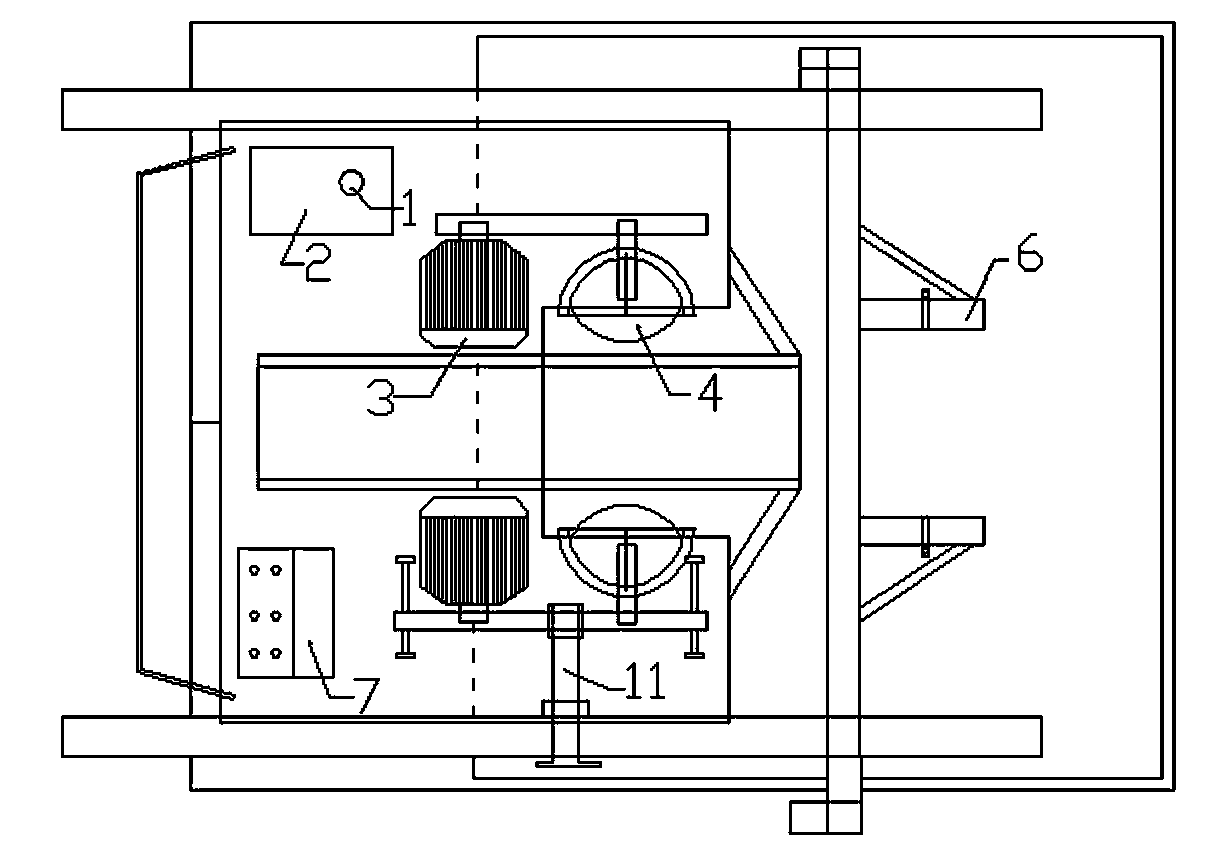

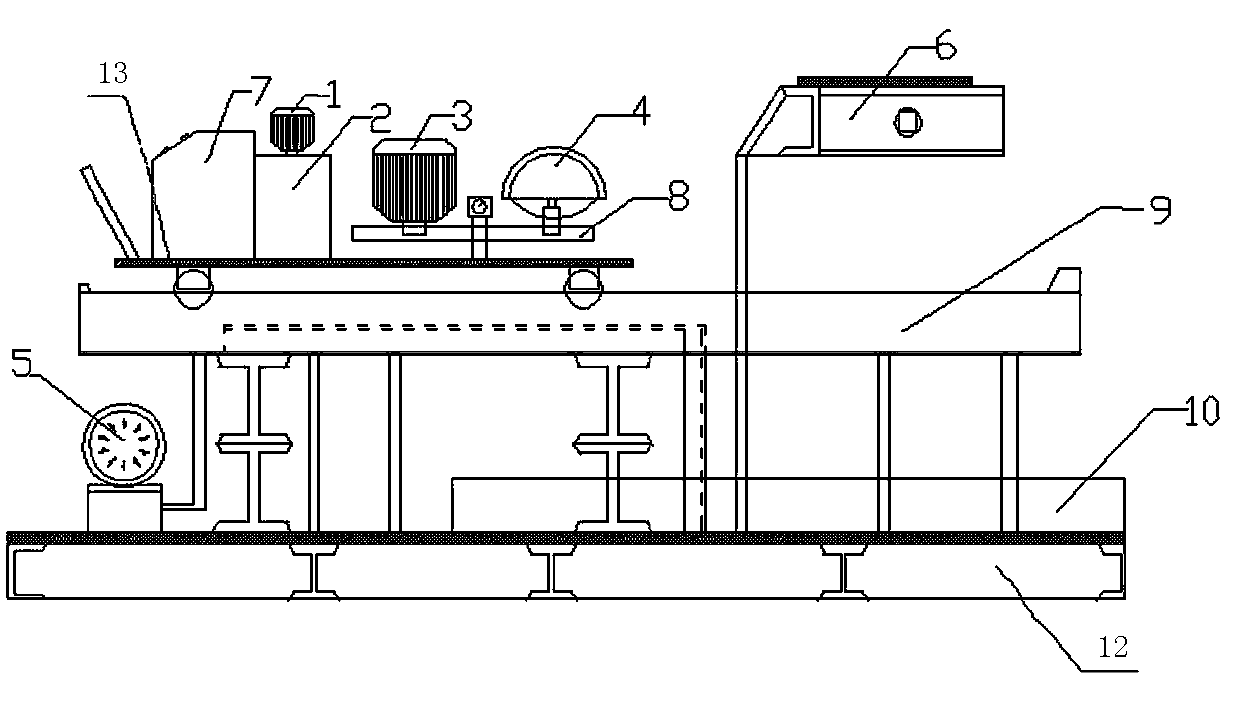

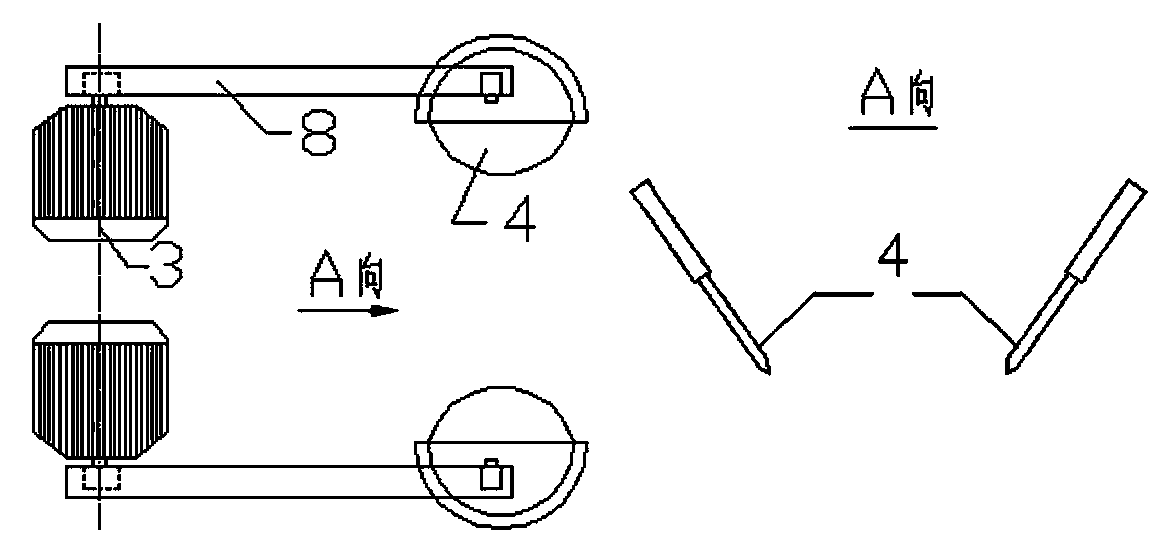

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a kind of anode guide rod automatic cutting equipment, it comprises base 12, and guide rod fixing frame 6 and walking track 9 are fixed on base 12 by bracket, and moving plate 13 is movably connected on walking track 9, and mobile plate 13 is installed There are electric control box 7 and cutting system, and described cutting system comprises the chainsaw motor 3 that is arranged on both sides of processing position, and each motor connects saw blade 4 through pulley transmission mechanism, and chainsaw motor 3 and saw blade 4 are all formed with the horizontal plane. The included angle is 45 degrees; the chainsaw motor 3 and the saw blade 4 on one side are integrally installed on the gap adjustment slider 11, and the gap adjustment slider 11 controls the gap between the saw blades ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com