Preparation method and application of flame retardant dye

A technology of flame retardant dyes and azo dyes, applied in the preparation, dyeing, azo dyes and other directions of azo dyes, can solve problems such as energy consumption, achieve durable flame retardant performance, save raw material and equipment costs, and reduce finishing The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

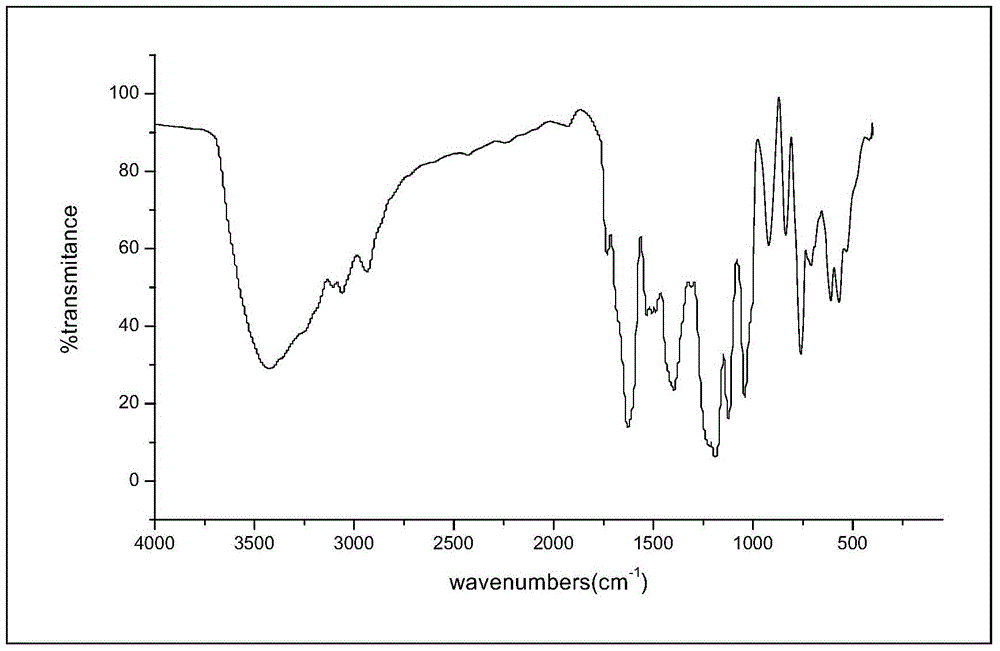

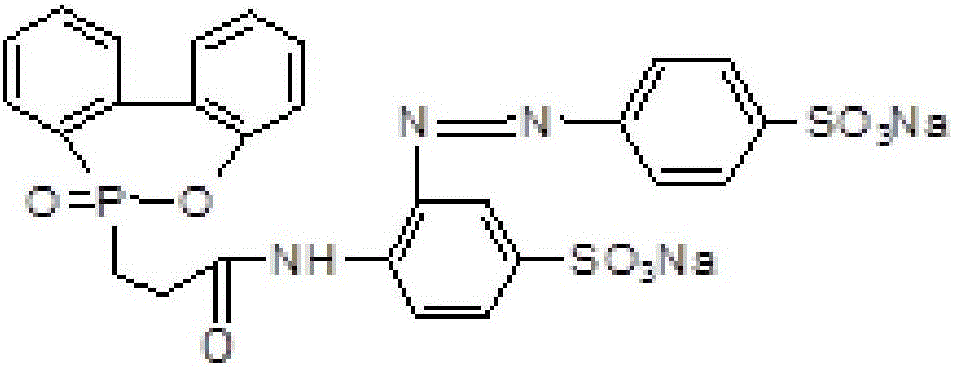

[0032] The chemical formula for preparing flame retardant dyes in the present embodiment is:

[0033]

[0034] Its synthetic method is carried out according to the following steps:

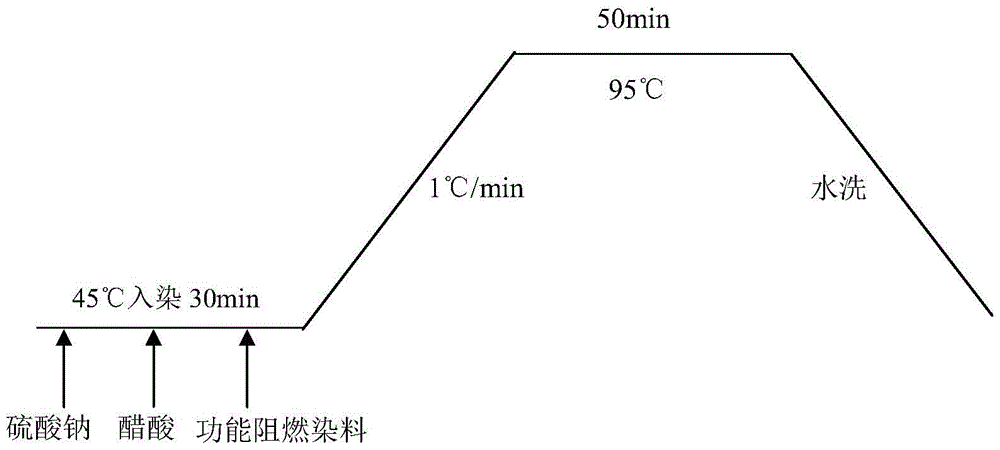

[0035] (1) Dissolve 0.01mol of sodium p-aminobenzenesulfonate in 50mL of water, add 0.012mol of sodium nitrite after cooling, stir, then pour this solution into a stirrer equipped with 25g of ice water and 5mL of hydrochloric acid (concentration 36 %) in the beaker, stirring, white powdery diazonium salt precipitates out. Add an appropriate amount of urea to the above solution until the potassium iodide test paper has no color, adjust the pH to 9-10 with aqueous sodium carbonate solution, add dropwise 50 mL of an aqueous solution containing 0.01 mol of sodium p-aminobenzenesulfonate in an ice-water bath, and react for 3 hours. After the above reaction is completed, ammonium sulfate is added for salting out, filtered, and dried to obtain a powdery yellow solid product: 2-amino-4', 5-disulfonic ...

Embodiment 2

[0046] The chemical formula of the flame retardant dye prepared in the present embodiment is as shown in embodiment one, and its synthetic method is carried out according to the following steps:

[0047] (1) Dissolve 0.02mol of sodium p-aminobenzenesulfonate in 50mL of water, add 0.025mol of sodium nitrite after cooling, stir, then pour this solution into a stirrer equipped with 50g of ice water and 10mL of hydrochloric acid (concentration 36 %) in the beaker, stirring, white powdery diazonium salt precipitates out. Add an appropriate amount of urea to the above solution until the potassium iodide test paper has no color, adjust the pH to 9-10 with aqueous sodium carbonate, and add 50 mL of an aqueous solution containing 0.02 mol of sodium p-aminobenzenesulfonate dropwise in an ice-water bath, and react for 3 hours. After the above reaction is completed, ammonium sulfate is added for salting out, filtered, and dried to obtain a powdery yellow solid product: 2-amino-4', 5-disul...

Embodiment 3

[0054] The chemical formula of the flame retardant dye prepared in the present embodiment is as shown in embodiment one, and its synthetic method is carried out according to the following steps:

[0055] (1) Dissolve 0.025mol of sodium p-aminobenzenesulfonate in 50mL of water, add 0.027mol of sodium nitrite after cooling, stir, then pour this solution into a stirrer equipped with 50g of ice water and 15mL of hydrochloric acid (concentration 36 %) in the beaker, stirring, white powdery diazonium salt precipitates out. Add an appropriate amount of urea to the above solution until the potassium iodide test paper has no color, adjust the pH to 9-10 with aqueous sodium carbonate solution, add dropwise 50 mL of an aqueous solution containing 0.025 mol of sodium p-aminobenzenesulfonate in an ice-water bath, and react for 3 hours. After the above reaction is completed, ammonium sulfate is added for salting out, filtered, and dried to obtain a powdery yellow solid product: 2-amino-4', ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com