Organic fluorine modified polyacrylate nanometer emulsion and nanometer composite adhesive

A technology of polyacrylate and nanoemulsion, applied in the direction of polyurea/polyurethane adhesive, ester copolymer adhesive, adhesive type, etc., can solve the problems of unsatisfactory washing fastness and high crosslinking degree, etc. Achieve good washing fastness, good adhesion and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

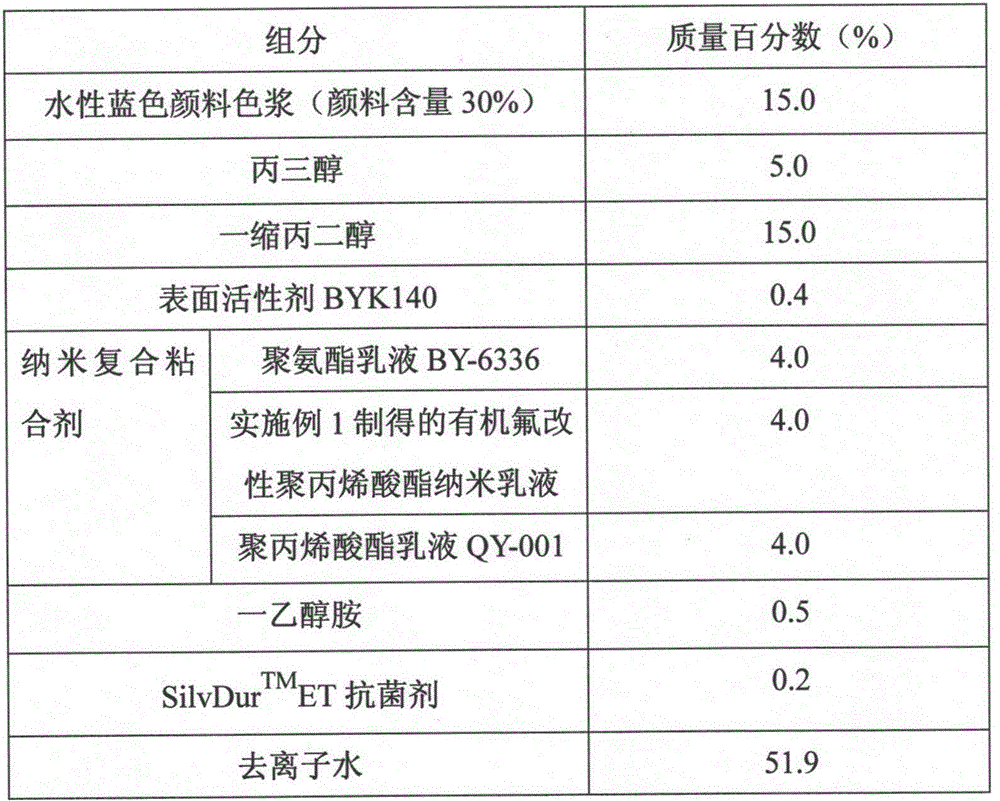

Examples

Embodiment 1

[0028] A kind of organic fluorine modified polyacrylate nanoemulsion, its synthetic method is: with 12.3g methyl methacrylate (MMA), 2.7g hexafluorobutyl methacrylate (HFBM), 0.6g emulsifying agent (by Xiao trouble 465. Sodium dodecyl sulfate (SDS) is mixed at a mass ratio of 1:1), 0.5 g of ethylene glycol dimethacrylate is added to 20 g of water, stirred at a high speed of 2500 rpm, and pre-emulsified for 30 minutes to obtain a pre-emulsified monomer. lotion. Then, 30 g of monomer pre-emulsion was added into the three-necked flask, the temperature was raised to 80° C., and 4 g of initiator potassium persulfate aqueous solution (concentration: 0.82%) was added to react for 30 min. Then use the dropping funnel to drop 6g initiator potassium persulfate aqueous solution (concentration 0.82%) and the pre-emulsion of the remaining monomers into the three-necked bottle simultaneously and slowly (10 drops / min), react for 2h, and obtain the required The organic fluorine-modified poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com