Waterborne foamed velvet solvent-free compound polyurethane synthetic leather for sofas and preparation method of waterborne foamed velvet solvent-free compound polyurethane synthetic leather

A synthetic leather and polyurethane technology, applied in textiles and papermaking, can solve problems such as insufficient production efficiency, poor hydrolysis resistance, and many processing procedures, and achieve simple production procedures, good hydrolysis resistance, and a green production environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

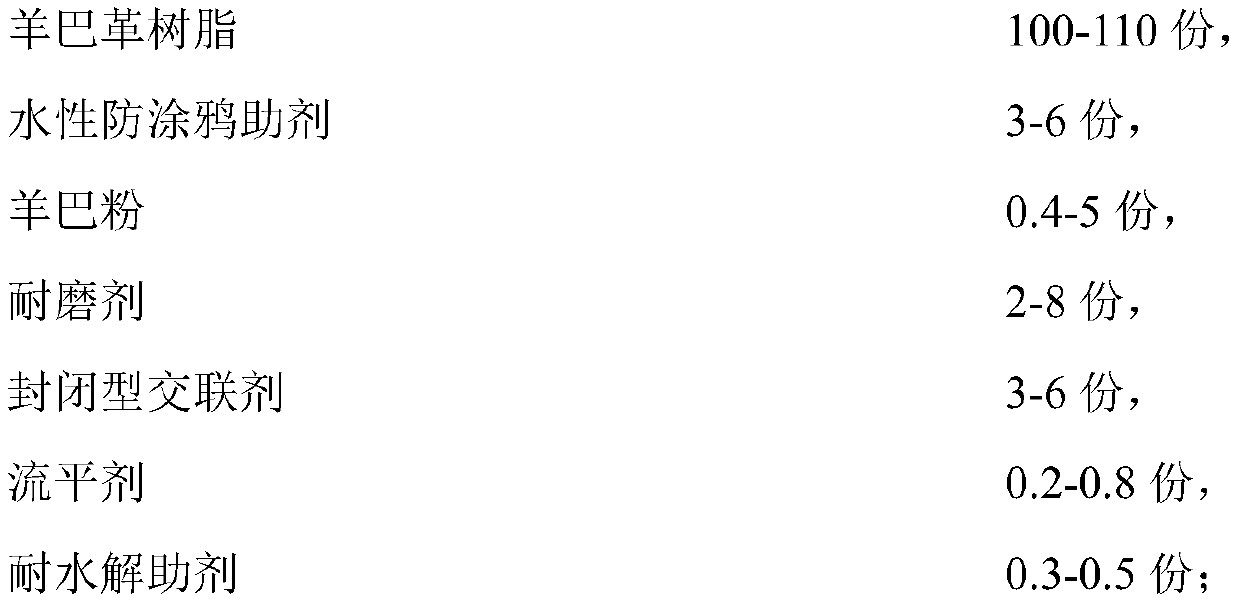

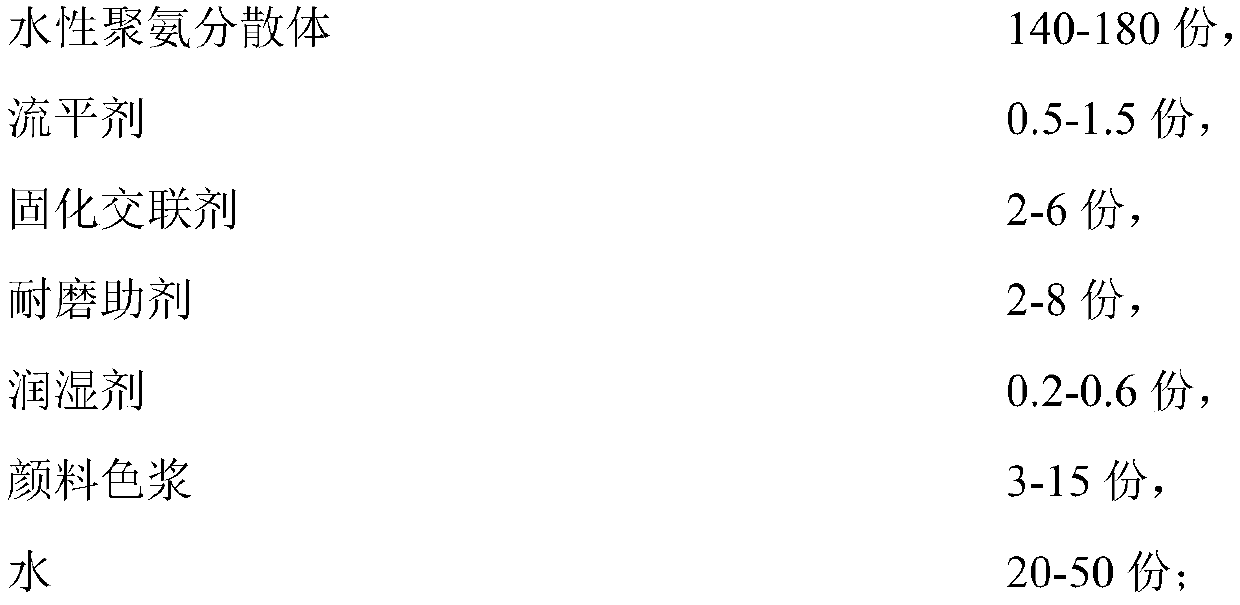

Method used

Image

Examples

Embodiment 1

[0060] 1. Dissolve 160 parts of RU-92-103, 8 parts of color paste, 2 parts of PTEF, 2 parts of 3238, 4 parts of XR-5580, 0.8 parts of LA-1610, 0.5 parts of LT-7100 in 30 parts of water, and the surface layer The slurry is fully stirred and mixed evenly, then pumped to a vacuum, and then evenly coated on the front of the plain release paper as the surface layer, and the coating thickness of the surface layer slurry is 0.04mm;

[0061] 2. Dissolve 150 parts of RU-92-279, 8 parts of color paste, 2 parts of 3238, 4 parts of XR-5580, 0.7 part of LA-1610, 0.2 part of ST-7110 in 50 parts of water, and then make the middle layer slurry After fully stirring and mixing evenly, after vacuuming, apply it evenly on the surface layer to prepare the middle layer. The thickness of the middle layer slurry is 0.09mm; the surface layer and the middle layer are air-dried at 90°C for 3 minutes ;

[0062] 3. Mix 120 parts of AL-2170A, 52 parts of AL-5040B, 0.2 parts of Chisorb 234, and 0.2 parts o...

Embodiment 2

[0066] 1. Dissolve 175 parts of RU-92-103, 12 parts of color paste, 3 parts of PTEF, 3 parts of 3238, 0.9 parts of LA-1610, 0.6 parts of LT-7100 in 40 parts of water, fully stir and mix the surface layer slurry After that, it is pumped to a vacuum, and then evenly coated and scratched on the front of the plain release paper as the surface layer, and the coating thickness of the surface layer slurry is 0.05mm;

[0067] 2. Dissolve 160 parts of RU-92-279, 13 parts of color paste, 2 parts of 3238, 0.8 part of LA-1610, 0.3 part of ST-7110 in 55 parts of water, then fully stir and mix the middle layer slurry evenly before pumping After vacuuming, apply it evenly on the surface layer to make the middle layer. The thickness of the middle layer slurry is 0.12mm; the surface layer and the middle layer are air-dried at 95°C for 2 minutes;

[0068] 3. Mix 140 parts of AL-2170A, 56 parts of AL-5040B, 0.3 parts of Chisorb 234, and 0.2 parts of Chisorb 944, mix and stir evenly, then evacuat...

Embodiment 3

[0072] 1. Dissolve 155 parts of RU-92-103, 8 parts of color paste, 3 parts of PTEF, 5 parts of 3238, 0.6 parts of LA-1610, 0.4 parts of LT-7100 in 50 parts of water, fully stir and mix the surface layer slurry After that, it is pumped to a vacuum, and then evenly coated and scratched on the front of the plain release paper as the surface layer, and the coating thickness of the surface layer slurry is 0.05mm;

[0073] 2. Dissolve 140 parts of RU-92-279, 11 parts of color paste, 3 parts of 3238, 0.4 parts of LA-1610, and 0.5 parts of ST-7110 in 55 parts of water, then fully stir the middle layer slurry and pump it evenly After vacuuming, apply it evenly on the surface layer to make the middle layer. The thickness of the middle layer slurry is 0.11mm; the surface layer and the middle layer are air-dried at 90°C for 3 minutes;

[0074] 3. Mix 140 parts of AL-2170A, 62 parts of AL-5040B, 0.3 parts of Chisorb 234, and 0.3 parts of Chisorb 944, mix and stir evenly, then evacuate it, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softness | aaaaa | aaaaa |

| Softness | aaaaa | aaaaa |

| Softness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com