Reactive dye ink jet printing sizing agent for cotton fabric

A reactive dye, inkjet printing technology, applied in dyeing, plant fibers, textiles and papermaking, etc., can solve the problems of low degree of substitution, affecting the color yield of digital inkjet printing, and rough texture of printed cotton fabrics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of sizing agent for inkjet printing of cotton fabric reactive dye ink, its basic composition and mass percentage are:

[0020] Sodium Alginate 30%

[0021] Sodium Carboxymethyl Cellulose 30%

[0022] Hydroxypropyl Guar Gum 35%

[0023] Dispersant 4%

[0024] Anti-migration agent 1%

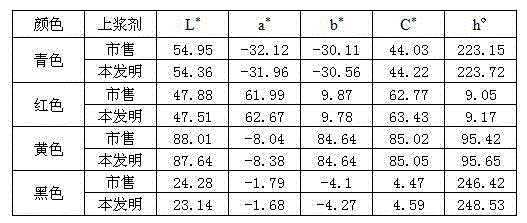

[0025] To prepare 1000g of inkjet printing sizing agent for cotton fabric reactive dye ink, 300g of sodium alginate, 300g of sodium carboxymethylcellulose, 350g of hydroxypropyl guar gum, 40g of dispersant, and 10g of anti-swimming agent were stirred evenly. Sizing process: 90% water, 5% urea, 3% baking soda, 2% sizing agent for inkjet printing of cotton fabric reactive dye ink, stirring for 90 minutes at a stirring speed of 450 rpm, and puffing at 20°C for 8 hours. Stenter sizing pretreatment; the same amount of commercially available sizing agent is used to sizing and pretreat the same cotton fabric on the stenter. Cotton fabrics pretreated with different sizing agents were pr...

Embodiment 2

[0029] A kind of sizing agent for inkjet printing of cotton fabric reactive dye ink, its basic composition and mass percentage are:

[0030] Sodium Alginate 35%

[0031] Sodium Carboxymethyl Cellulose 30%

[0032] Hydroxypropyl Guar Gum 30%

[0033] Dispersant 3%

[0034] Anti-migration agent 2%

[0035] To prepare 1000 g of inkjet printing sizing agent for cotton fabric reactive dye ink, 350 g of sodium alginate, 300 g of sodium carboxymethyl cellulose, 300 g of hydroxypropyl guar gum, 30 g of dispersant, and 20 g of anti-migration agent were stirred evenly. Sizing process: 89.5% water, 5% urea, 3% baking soda, 2.5% sizing agent for inkjet printing of cotton fabric reactive dye ink, stirring for 90 minutes at a stirring speed of 450 rpm, and puffing at 20°C for 8 hours. The same amount of commercially available sizing agent was used for sizing pretreatment on the tenter frame to sizing the same cotton fabric. Cotton fabrics pretreated with different sizing agents were pr...

Embodiment 3

[0039] A kind of sizing agent for inkjet printing of cotton fabric reactive dye ink, its basic composition and mass percentage are:

[0040] Sodium Alginate 30%

[0041] Sodium Carboxymethyl Cellulose 35%

[0042] Hydroxypropyl Guar Gum 30%

[0043] Dispersant 3%

[0044] Anti-migration agent 2%

[0045] To prepare 1000g of inkjet printing sizing agent for cotton fabric reactive dye ink, 300g of sodium alginate, 350g of sodium carboxymethylcellulose, 300g of hydroxypropyl guar gum, 30g of dispersant, and 20g of anti-swimming agent were stirred evenly. Sizing process 89% water, 5% urea, 3% baking soda, cotton fabric reactive dye ink inkjet printing sizing agent 3%, stirring at a stirring speed of 450 rpm for 90 minutes, keeping the temperature at 20°C for 8 hours after puffing The same amount of commercially available sizing agent was used for sizing pretreatment on the tenter frame to sizing the same cotton fabric. Cotton fabrics pretreated with different sizing agents we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com