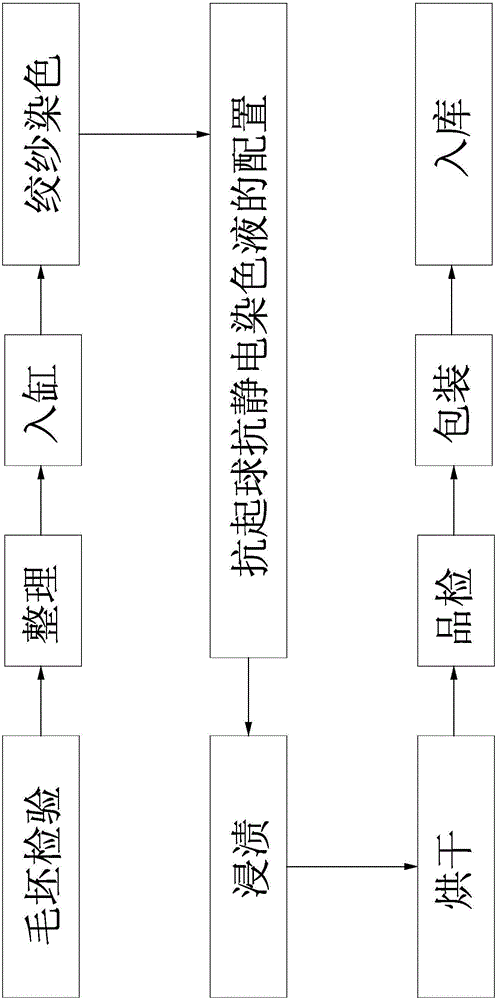

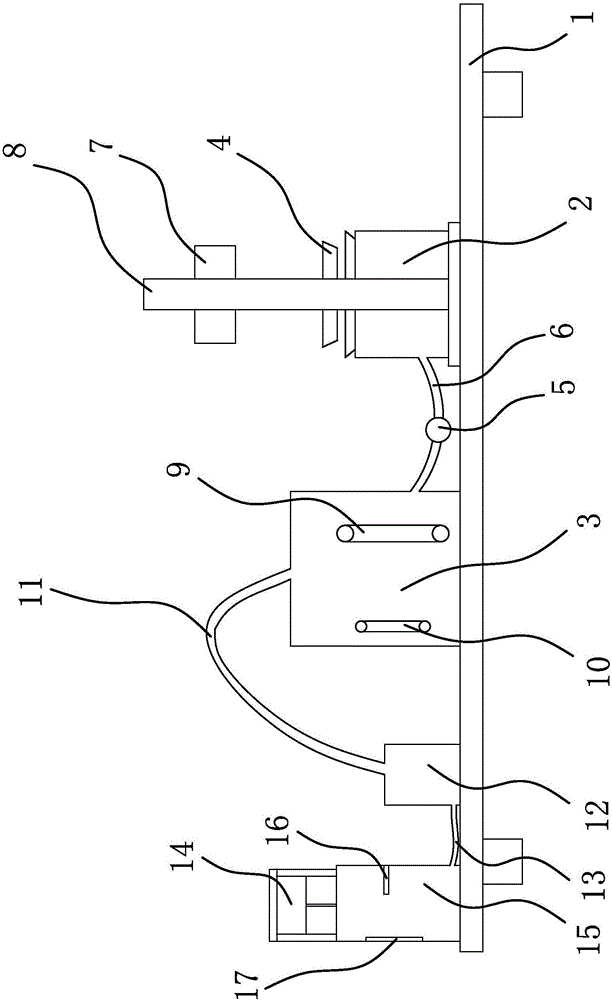

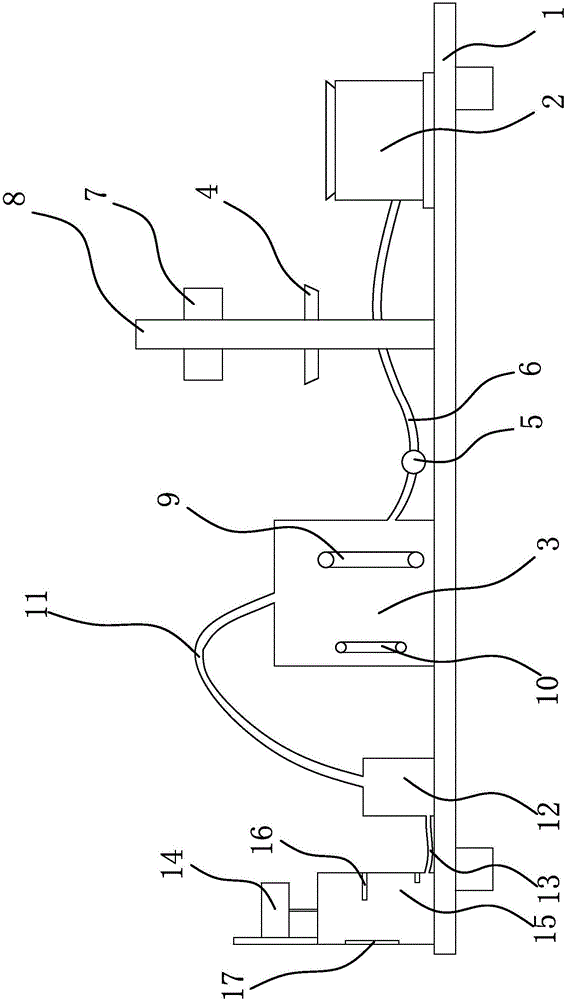

Dyeing and finishing process of antipilling-antistatic yarn and automatic impregnator for dyeing and finishing process

An anti-pilling and anti-static technology, applied in textile processing machine accessories, textile material processing, liquid/gas/steam yarn/filament processing, etc., can solve problems such as low impregnation efficiency and insufficient impregnation, and achieve convenience operation, reducing the finishing process, increasing the effect of the application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Immerse the imitation cashmere yarn in 2% compound anti-pilling and antistatic working solution for 30 minutes, the temperature of the soaking solution is 50°C, dehydrate, the rate of liquid retention is controlled at about 30%, the drying temperature is 100°C, and the drying time is 15 minutes. The anti-pilling evaluation grade is 3.5, the static voltage half-life is 0.4s, and the antistatic evaluation grade is A grade.

Embodiment 2

[0068] Immerse the anti-pilling imitation cashmere yarn in 2% compound anti-pilling and antistatic working solution for 30 minutes, dehydrate at the temperature of the soaking solution at 50°C, control the liquid-carrying rate at about 30%, dry at 100°C, and dry The time is 15 minutes. The anti-pilling evaluation grade is grade 4, the static voltage half-life is 0.23s, and the antistatic evaluation grade is grade A.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com