Method and device for removing inner surface oxidized iron sheet of steel pipe on line

A technology of iron oxide scale and inner surface, which is applied in workpiece surface treatment equipment, metal processing equipment, metal rolling, etc., can solve problems such as overacid corrosion, grinding, shot blasting difficulties, lengthen the production cycle of steel pipes, etc., and achieve cost improvement , Reduce the effect of the finishing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

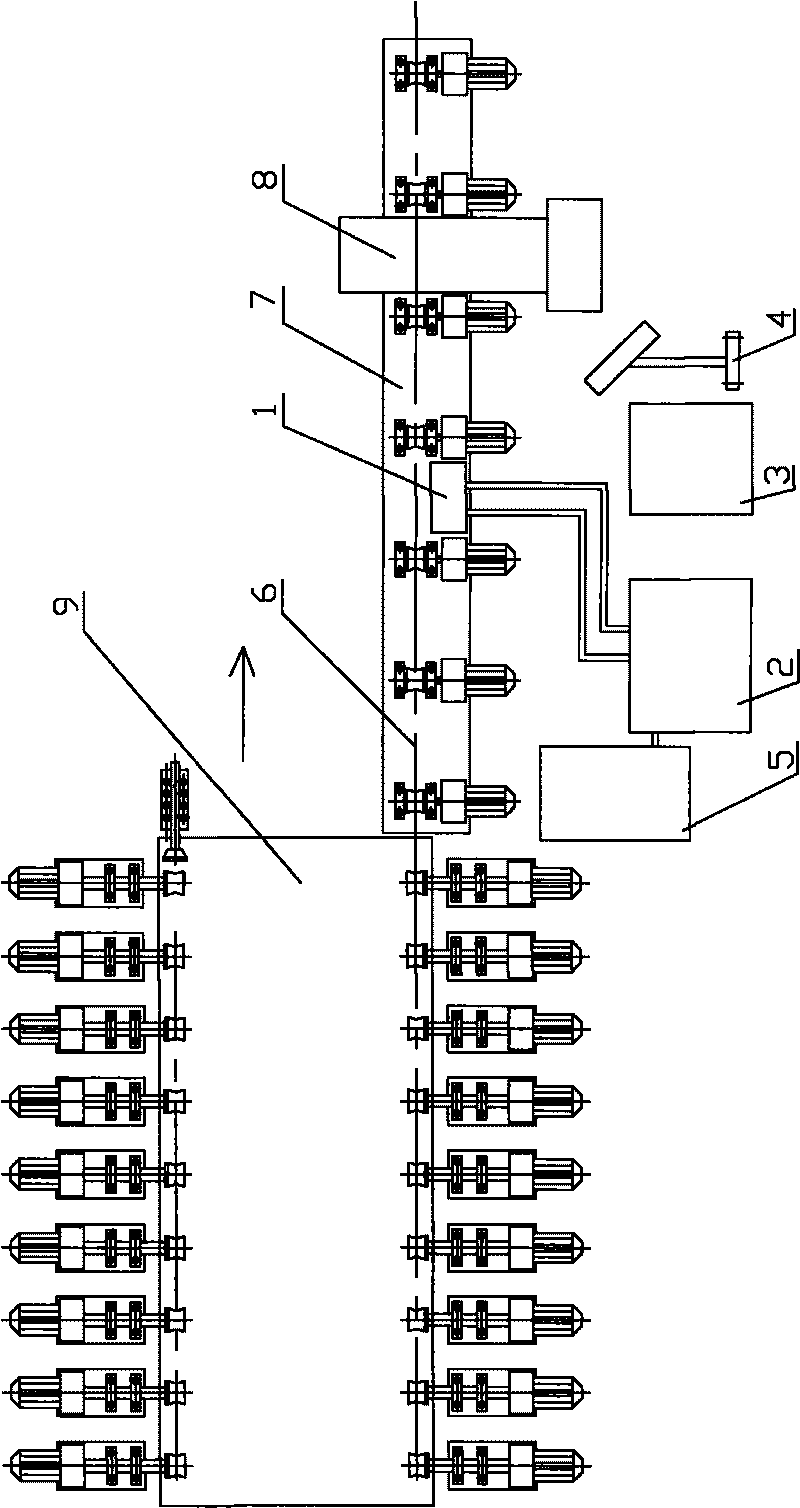

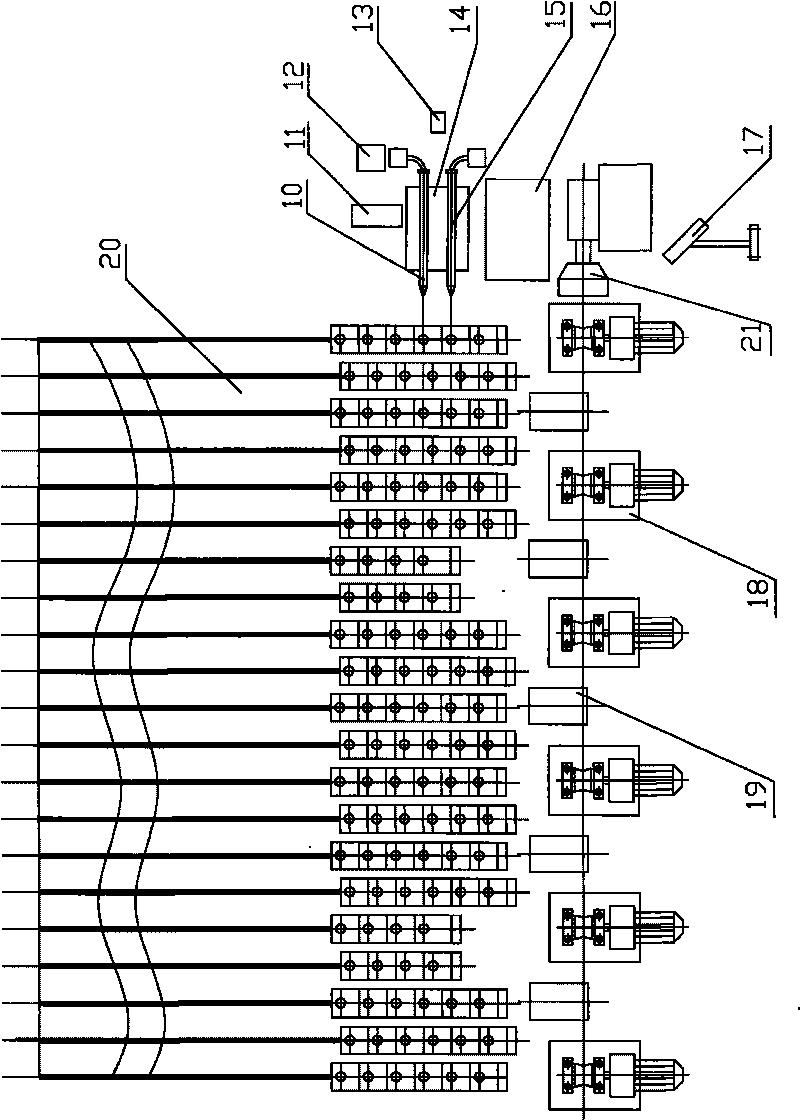

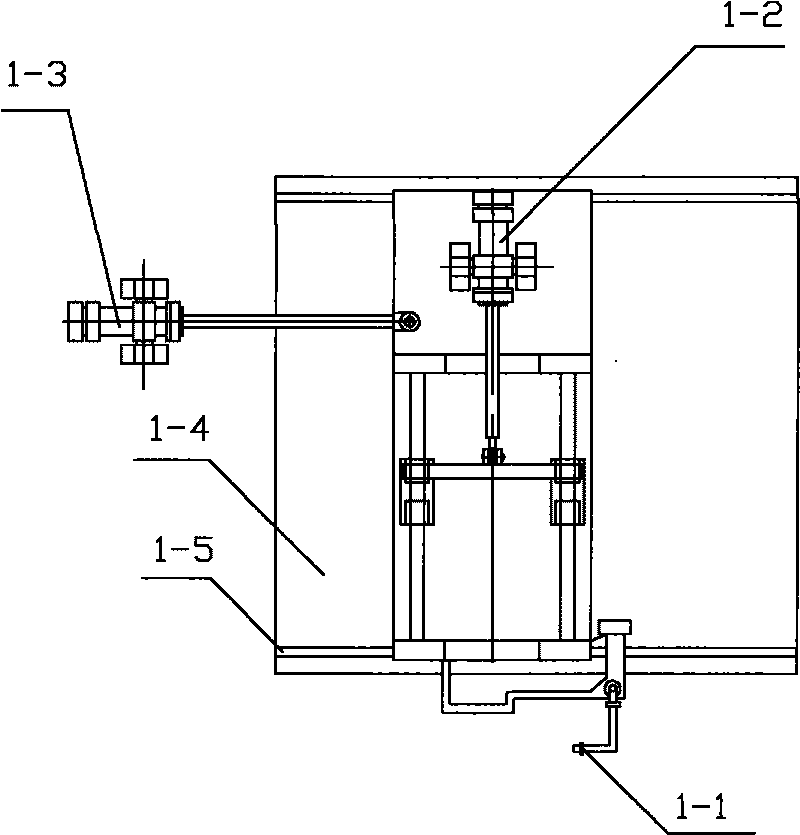

[0026] As shown in the accompanying drawings, a method for removing iron scale on the inner surface of a steel pipe line, which is the third roller table and the fourth roller table between the step-by-step reheating furnace 9 and the high-pressure water descaling box 8 A water spray trolley 1 equipped with a water spray device was designed and produced during the period. The water spray trolley 1 is controlled by the push-pull oil cylinder 1-3 of the trolley, and the nozzle 1-1 is controlled by a high-pressure pneumatic stop valve. 4 After the detection, the water spray trolley 1 runs, the high-pressure pneumatic stop valve opens, the nozzle 1-1 on the water spray trolley 1 sprays a certain flow of high-pressure water into the inner hole at the end of the steel pipe, and the water spray trolley 1 follows the steel pipe for a certain distance and is controlled by After the water spraying time is extended by the PLC program control, the water spraying trolley 1 stops spraying wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com