A sheet automatic shearing machine

A cutting machine and automatic technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of high labor intensity, disordered collection effect, low work efficiency, etc., to reduce labor intensity and improve magnetic sheet products Quality and work efficiency improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

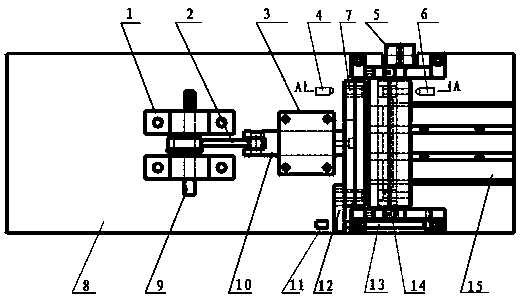

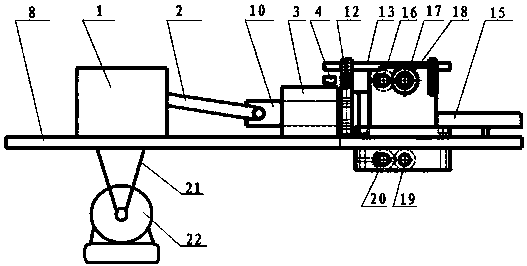

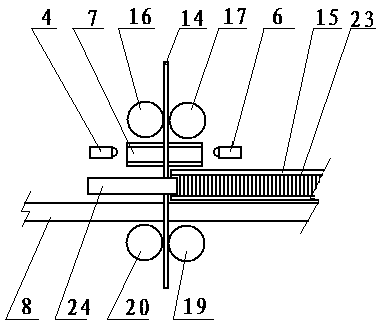

[0015] A kind of sheet material automatic shearing machine, comprises the workbench 8 of horizontal arrangement, has the vertical slit on the workbench 8, is installed above the slit upper active feeding roller 17 and the upper driven feeding roller 16, on the slit The bottom is equipped with the lower active feed roller 19 and the lower driven feed roller 20, the upper active feed roller 17 is driven by the feed motor 5, and there is a synchronous transmission connection between the upper active feed roller 17 and the lower active feed roller 19, and the feed motor 5 Under the control of the control mechanism, the upper active feeding roller 17 and the lower active feeding roller 19 are realized to rotate synchronously, the gap between the upper active feeding roller 17 and the upper driven feeding roller 16, the lower active feeding roller 19 and the lower driven feeding roller The gap between the rollers 20 is on the same vertical line as the slit on the workbench 8, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com