A kind of digital printing paste

A technology of digital printing and sizing, applied in dyeing, textile and papermaking, etc., can solve the problems of poor hand feeling, poor water retention, poor coloring ability, etc., and achieve the effect of reducing finishing process, improving water retention performance, and improving anti-wrinkle performance.

Inactive Publication Date: 2016-01-20

SUZHOU INST OF TRADE & COMMERCE

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The modified starch of the digital printing paste in the prior art mostly adopts corn modified starch, wheat modified starch, etc., which has poor water retention, poor dyeing effect of dye ink, poor coloring ability, light color yield, and unclear printing pattern

The price of synthetic paste is high, and after digital printing, the excess printing paste is not easy to clean, resulting in stiff printed fabric and poor hand feeling

Urea contains N element and is used in a large amount. The N element in the wastewater in the production process is likely to cause eutrophication of the water body and lead to algal blooms, which has great environmental pollution.

[0004] The anti-wrinkle performance of silk-cotton blended fabrics is poor, and it consumes water and energy for finishing alone. The digital printing slurry used in the prior art is used to print silk-cotton blended fabrics, and the shade of digital printing is not bright.

Existing digital printing pastes have no effect on improving the wrinkle resistance of silk-cotton blended fabrics

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

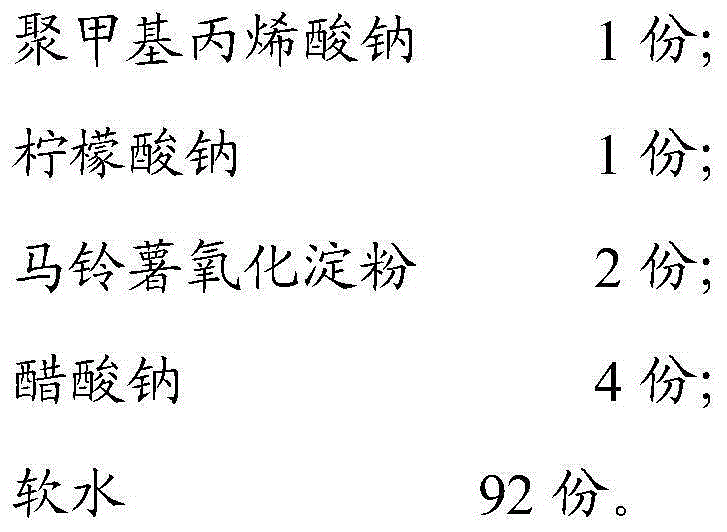

Embodiment 1

[0023] A digital printing slurry, comprising the following components mixed in parts by weight:

[0024]

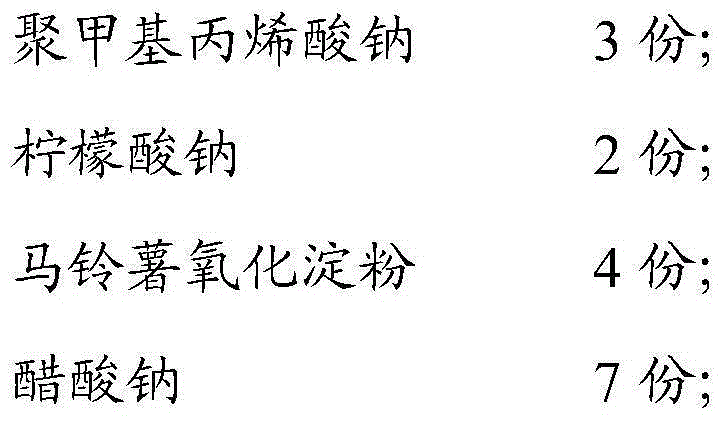

Embodiment 2

[0026] A digital printing slurry, comprising the following components mixed in parts by weight:

[0027]

[0028]

Embodiment 3

[0030] A digital printing slurry, comprising the following components mixed in parts by weight:

[0031]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses digital printing paste which comprises the following components, by weight: 1-3 parts of thickeners, 1-2 parts of anti-wrinkling agents, 2-4 parts of potato oxidized starch, 4-7 parts of hygroscopic agents and 84-92 parts of water. The components of the digital printing paste have mutually synergistic effect, so that water-retaining property and viscosity of the digital printing paste are improved, and dyeing effect of dye-based ink is good. Fabrics subjected to digital printing through the digital printing paste have deeper and brighter colors and clear design, and no color penetration happens. By means of the anti-wrinkling agents, anti-wrinkling performance of silk cotton blended fabrics is improved greatly, a finishing procedure after printing of the silk cotton blended fabrics is omitted, and energy is saved. Pollution to the environment caused by the waste produced in the process of the digital printing paste is greatly reduced. The digital printing paste is fewer in components and convenient to prepare.

Description

technical field [0001] The invention relates to a digital printing slurry, which can be used for digital printing of silk and cotton blended fabrics. Background technique [0002] Compared with traditional printing technology, digital inkjet printing technology has obvious advantages, no need for net making, low energy consumption, no waste, high precision, unlimited colors, wide application, and can adapt to the market demand of personalization, small batch and quick response . In recent years, digital inkjet printing technology has developed rapidly. [0003] The ingredients of digital printing slurry in the prior art include sodium alginate, modified starch, starch, synthetic paste, urea, sodium bicarbonate, sodium sulfate and the like. The modified starch of the digital printing paste in the prior art mostly adopts corn modified starch, wheat modified starch, etc., which has poor water retention, poor dyeing effect of dye ink, poor coloring ability, light color yield, ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): D06P1/58D06P1/653D06P1/48D06P1/81D06P3/82

Inventor 许磊陶然周燕

Owner SUZHOU INST OF TRADE & COMMERCE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com