The making method of the ground jack copper panel and copper up-cover

A technology of ground socket and manufacturing method, which is applied to the base/casing, electrical components, circuits, etc., can solve the problems of inability to improve product quality, large damage to casting molds, low product yield, etc., and achieve significant social and environmental benefits. The effect of reducing production costs and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

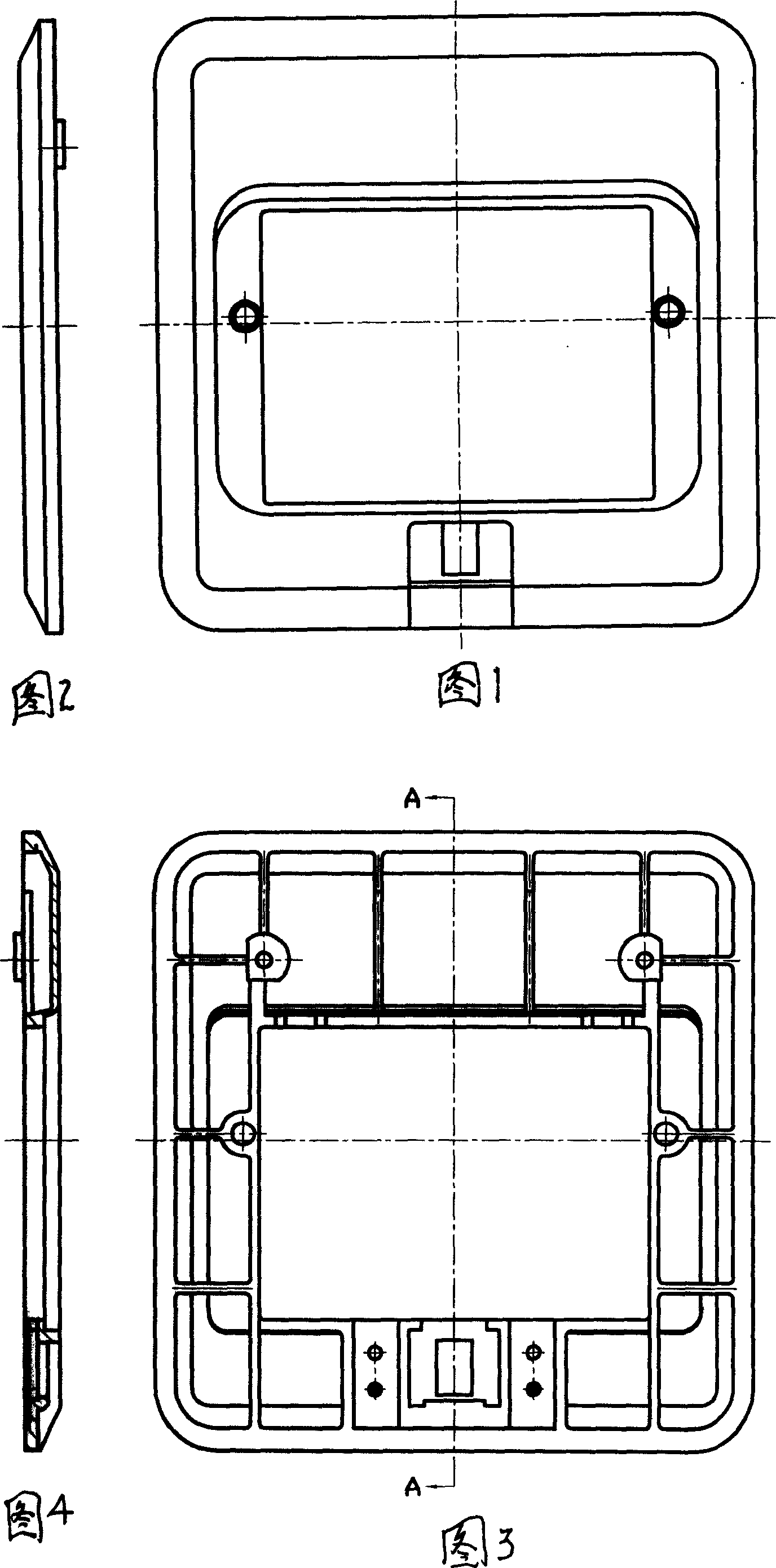

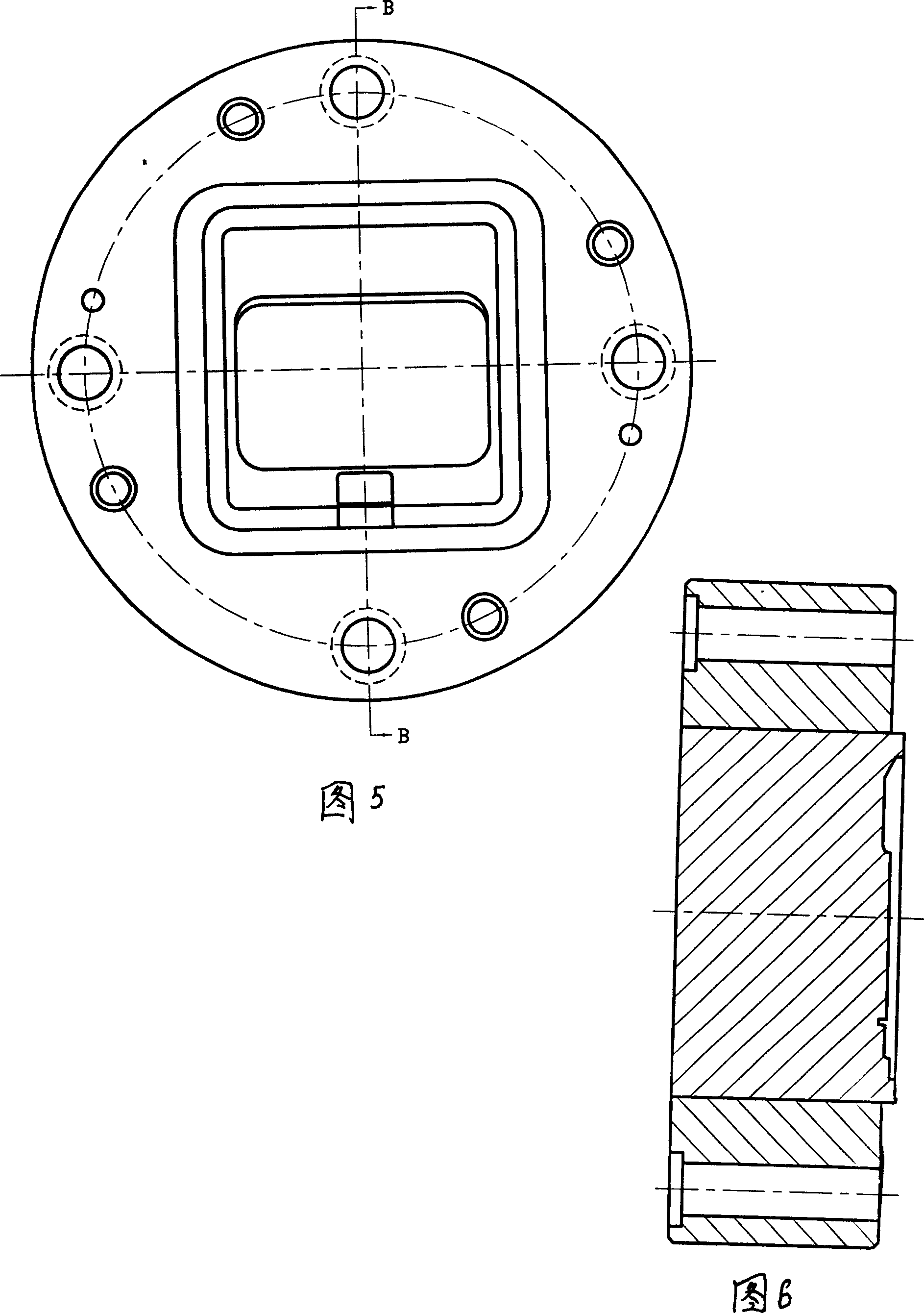

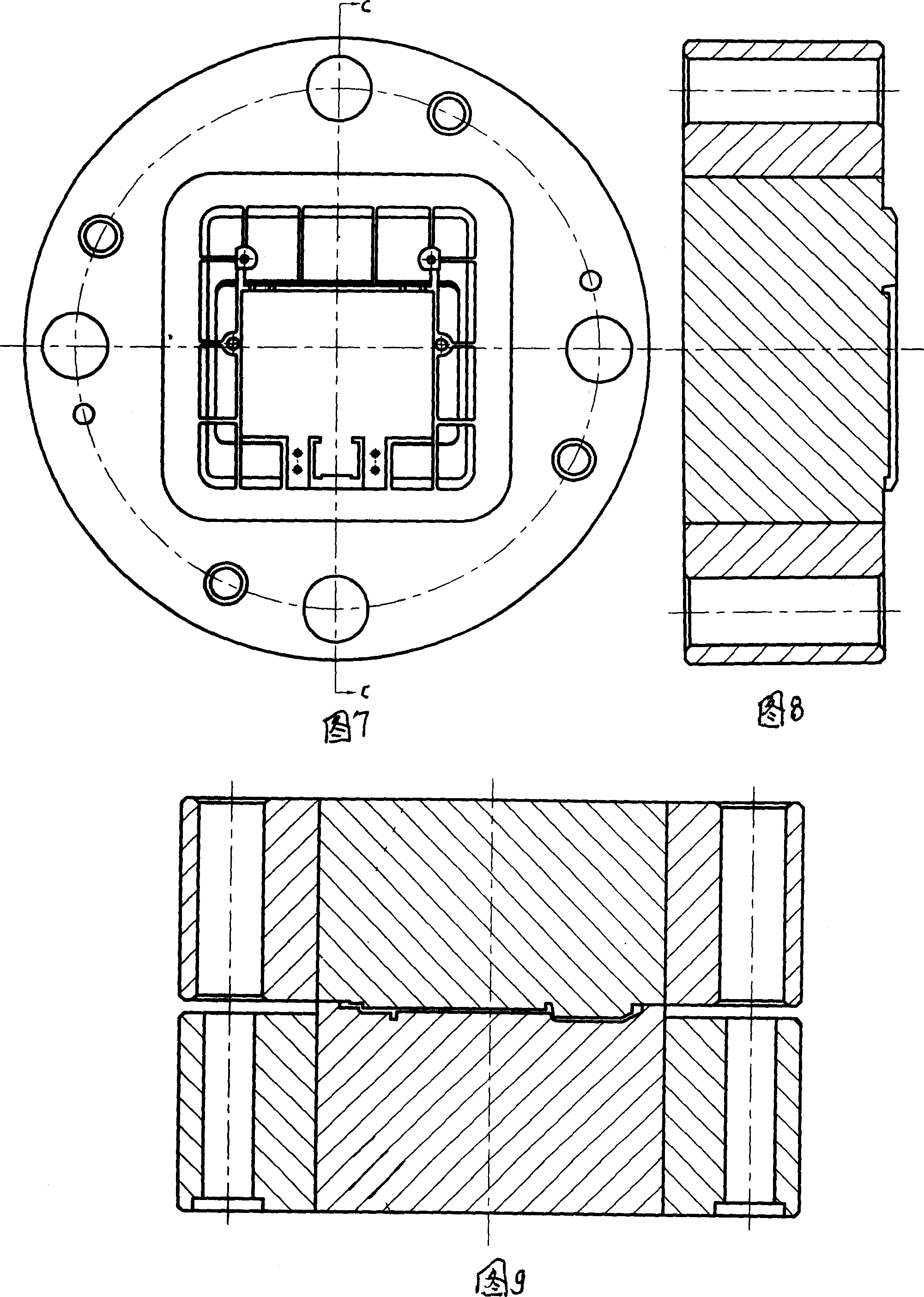

[0017] Embodiment 1: a kind of manufacture method of copper panel of ground socket, the copper rod that grade is H59, diameter is Φ50 is cut into the copper block of 30% more weight than copper panel finished product (see Fig. 1-Fig. 4), and copper block Heat until it turns red, and the forging die (see Figure 4-9) is installed in a friction press with a pressure of no less than 600 tons, and the copper block that has been burned to red is clamped into the forging die (see Figure 9) with pliers , At this time, immediately turn on the friction press for stamping and forming, and then use a punch and a special mold to punch holes and trim edges to obtain a finished copper panel (see Figure 1-Figure 4). The heating temperature of the copper block is 600°C.

Embodiment 2

[0018] Embodiment 2: A method for manufacturing a ground socket copper upper cover, cutting a copper rod with a grade of H59 and a diameter of Φ50 into a copper block with a weight 30% more than the finished copper upper cover, heating the copper block until it turns red, and forging The mold is installed in a friction press with a pressure of not less than 600 tons. The copper block that has been burned to red is clamped into the forging mold with pliers. At this time, the friction press is immediately turned on for stamping, and then punched with a punch and a special mold. , Trim the edge, and make the copper upper cover finished product. The heating temperature of the copper block is 600°C.

Embodiment 3

[0019] Embodiment three: a kind of manufacture method of copper panel of ground socket, the copper rod that grade is H58, diameter is Φ50 is cut into the copper block of 30% more weight than copper panel finished product (see Fig. 1-Fig. 4), and copper block Heat until it turns red, and the forging die (see Figure 4-9) is installed in a friction press with a pressure of no less than 600 tons, and the copper block that has been burned to red is clamped into the forging die (see Figure 9) with pliers , At this time, immediately turn on the friction press for stamping and forming, and then use a punch and a special mold to punch holes and trim edges to obtain a finished copper panel (see Figure 1-Figure 4). The heating temperature of the copper block is 500°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com