Anti-slippery bio-based rubber sole and preparation method and mold thereof

A rubber sole and bio-based technology, applied to shoe soles, other household appliances, footwear, etc., can solve the problems of easy precipitation of soybean oil and excessive carbon emissions, and achieve the effect of improving mechanical properties and increasing the degree of crosslinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

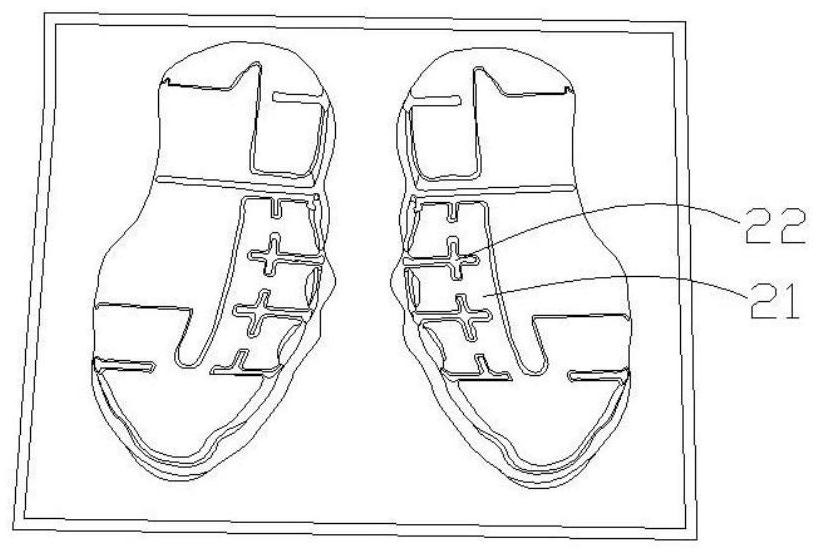

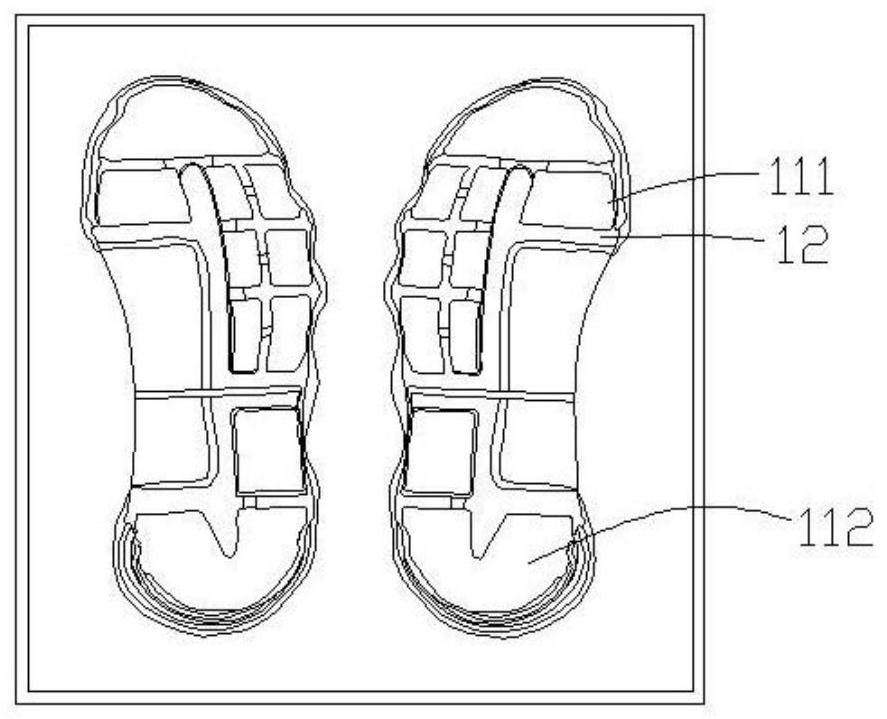

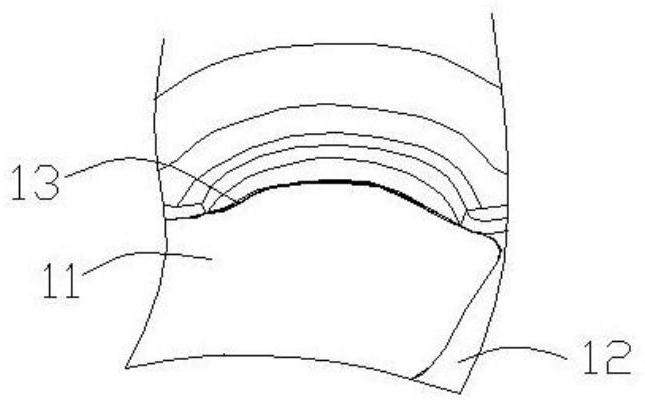

[0046] A rubber film mold is composed of an upper template and a lower template. refer to figure 1 , the upper template has an upper rubber base area 21 , an upper burr area 22 , and a first groove area 23 , and the upper rubber base area 21 is connected with the upper burr area 22 through the first groove area 23 . refer to figure 2 , image 3, the lower template has a lower rubber base area 11, a lower burr area 12, and a second groove area 13, the angle of the groove at the bottom of the second groove area 13 is 60 degrees, and the edge of the lower rubber base area 11 is connected with a second groove area 13 , the side of the second groove area 13 away from the lower rubber base area 11 is connected to the lower burr area 12 .

[0047] When the upper formwork is sealed and connected with the lower formwork, the upper rubber base area 21 coincides with the lower rubber base area 11, and the upper burr area 22 overlaps with the lower burr area 12. Refer to Figure 4 , ...

Embodiment 2

[0053] A preparation method of anti-wet skid bio-based rubber sole, comprising the steps of:

[0054] Step (1): The preparation method of bio-based solution-polymerized styrene-butadiene rubber: first, put 100 parts of carboxylated solution-polymerized styrene-butadiene rubber into a banbury mixer at a speed of 40-50 rpm, and banbury for two minutes; then put in zinc oxide 3 1 part, 1 part of stearic acid, heat is generated by system friction, and the temperature in the internal mixer gradually increases; when the temperature in the internal mixer rises to 85 ℃, add 27 parts of epoxy soybean oil, and continue banburying for 12 minutes; The resulting mixture is discharged from the internal mixer, transferred to a double-roll mill, calendered, and cooled to room temperature to obtain bio-based solution-polymerized styrene-butadiene rubber; among them, the carboxylated solution-polymerized styrene-butadiene rubber comes from Zhenjiang Chimei Chemical Co., Ltd. Co., Ltd.; epoxy so...

Embodiment 3

[0059] A preparation method of anti-wet skid bio-based rubber sole, comprising the steps of:

[0060] Step (1) The preparation method of bio-based solution-polymerized styrene-butadiene rubber: first, 100 parts of carboxylated solution-polymerized styrene-butadiene rubber are put into a banbury mixer at a speed of 40-50 rpm, and banburying for two minutes; then 3 parts of zinc oxide are put into , 1 part of stearic acid, heat is generated by system friction, and the temperature in the internal mixer gradually increases; when the internal temperature of the internal mixer rises to 85 ℃, add 20 parts of epoxy soybean oil, and continue banburying for 12 minutes; The obtained mixture is discharged from the internal mixer, transferred to a two-roll mill, calendered, and cooled to room temperature to obtain bio-based solution-polymerized styrene-butadiene rubber. Among them, carboxylated solution polystyrene butadiene rubber comes from Zhenjiang Chimei Chemical Co., Ltd.; epoxy soyb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com