Ordered harvester for closely planted vegetables

A technology for harvesters and vegetables, which is applied to harvesters, agricultural machinery and implements, applications, etc., can solve the problems of reducing the freshness of vegetables, low utilization rate of implements, and costing more people, so as to save the finishing process and achieve high harvesting efficiency , the effect of ingenious structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

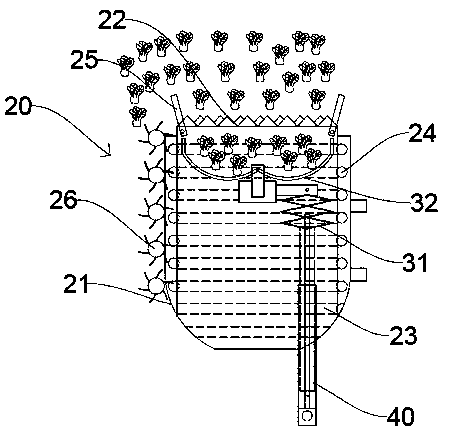

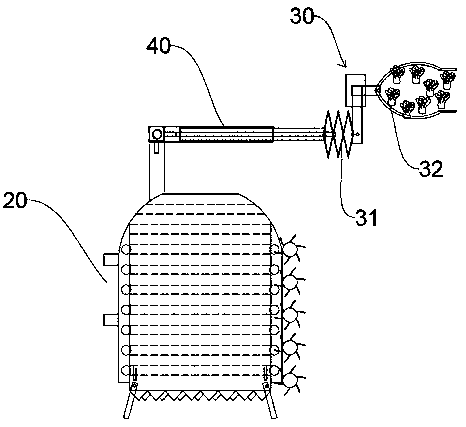

[0033] like Figure 1-11 As shown in the orderly harvester for densely planted vegetables, the front end of the harvester is equipped with a ring track 1 and a harvesting cart 20 that can move along the outer edge of the ring track 10 through a bracket. The harvesting cart 20 can be one or two.

[0034] Described harvesting trolley 20 comprises base 21, when moving along annular track 10, the broadside of base 21 is perpendicular to the advance direction of harvesting trolley 20 on annular track 10, and the front end of one end broadside of described base 21 is provided with a pair of Rows of cutting knives 22 are used to cut vegetables, on the base 21, at the rear end of the double row of cutting knives 22, a row of conveying wheels are set up successively to form a conveying platform 23 for conveying the vegetables that are cut by the double row of cutting knives 22 and constantly cut by new ones. For the vegetables that are pushed back, the two sides of the conveying platfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com