Preparation method of aromatic towel

An aromatic and towel technology, which is applied in dyeing, textile and papermaking, fiber treatment, etc., can solve the problems of wasting water, polluting the environment, and poor fragrance persistence, so as to save energy costs, reduce sewage discharge, and keep fragrance for a long time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing aromatic towels, the process flow: preparation of color paste → printing → drying → tenter → finished product,

[0024] Specific process prescription:

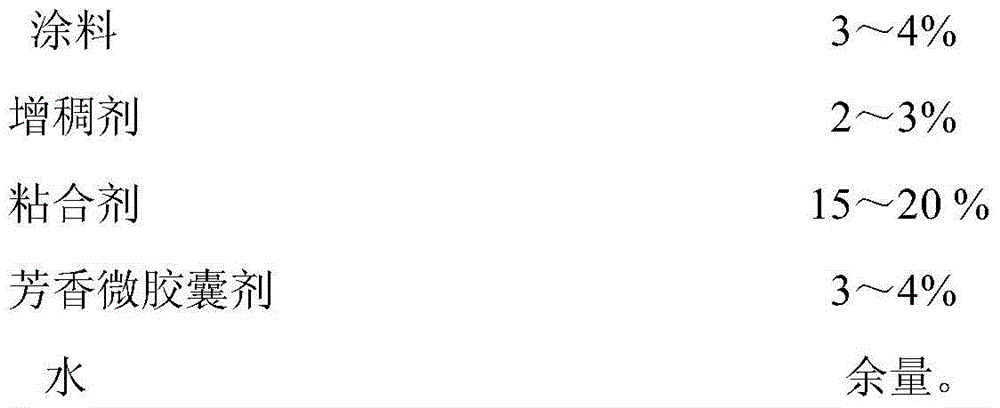

[0025] Each component of color paste by weight percentage is:

[0026]

[0027] The paint is: paint pink D-118; the adhesive is: Changzhou Hans-PDM; the thickener is: BASF HIT; the fragrance microcapsule is JN-001.

[0028] The present invention according to above-mentioned process prescription, concrete operations are as follows:

[0029] (1) During the preparation of the color paste, first add a thickener to part of the water and stir thoroughly to make it completely dissolved and puffed, then add adhesive, paint, and aromatic microcapsules in sequence and stir evenly.

[0030] (2) Printing: Printing with a rotary screen printing machine.

[0031] (3) Drying: The drying temperature is 80°C and the drying time is 5 minutes.

[0032] (4) Aromatic towels are produced after tentering.

Embodiment 2

[0034] A method for preparing aromatic towels, the process flow: preparation of color paste → printing → drying → tenter → finished product,

[0035] Specific process prescription:

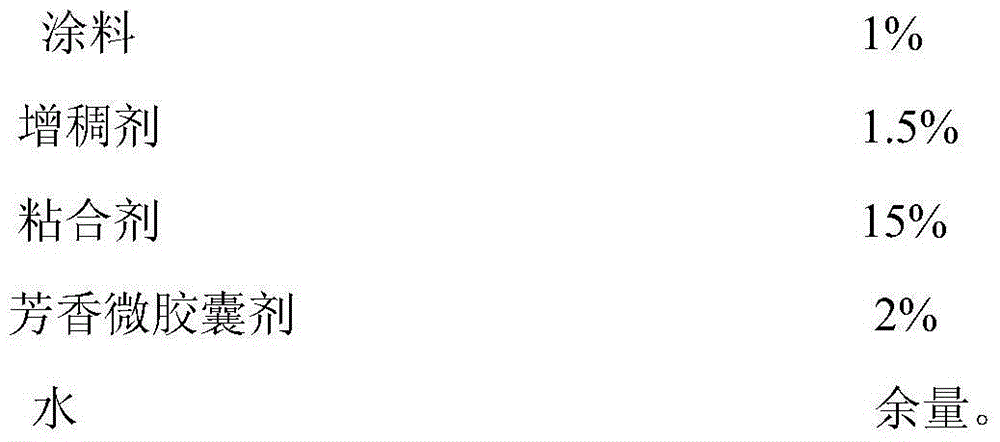

[0036] Each component of color paste by weight percentage is:

[0037]

[0038]

[0039] The paint is: paint blue D-301; the binder is: the binder is: Changzhou Hans-PDM; the thickener is: BASF HIT; the aromatic microcapsule is: JN-001.

[0040] The present invention according to above-mentioned process prescription, concrete operations are as follows:

[0041] (1) During the preparation of the color paste, first add a thickener to part of the water and stir thoroughly to make it completely dissolve and puff, then add adhesive, paint, and aromatic microcapsules and stir evenly;

[0042] (2) Printing: printing by rotary screen printing machine;

[0043] (3) Drying: drying temperature is 80°C, drying time is 5 minutes;

[0044] (4) Aromatic towels are produced after tentering.

Embodiment 3

[0046] A method for preparing aromatic towels, the process flow: color paste preparation→printing→drying→stenter→finished product, specific process prescription:

[0047] Each component of color paste by weight percentage is:

[0048]

[0049] The paint is: paint yellow KRC; the binder is: the binder is: Changzhou Hans-PDM; the thickener is: BASF HIT; the fragrance microcapsule is: JN-001.

[0050] The present invention according to above-mentioned process prescription, concrete operations are as follows:

[0051] (1) Preparation of color paste: first add thickener to part of the water and stir thoroughly to make it completely dissolved and puffed, then add adhesive, paint, and aromatic microcapsules in sequence and stir evenly.

[0052] (2) Printing: Printing with a rotary screen printing machine.

[0053] (3) Drying: The drying temperature is 100°C, and the drying time is 5 minutes.

[0054] (4) Aromatic towels are produced after tentering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com