Method for endless rolling of sectional material and rod and wire materials

A technology of endless rolling, bar and wire, applied in the direction of metal rolling, metal rolling, metal rolling stand, etc., can solve the problem of affecting the yield and product quality, not realizing the endless rolling of the billet, and the impact of the rolling mill. load and other problems, to achieve the effect of saving equipment investment and heating energy consumption, avoiding non-sizing and cutting losses, and reducing the finishing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

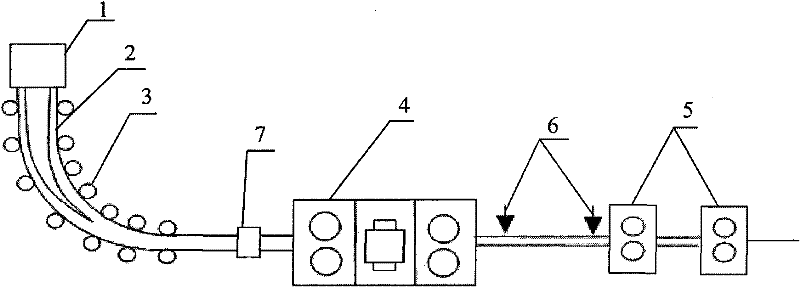

Embodiment 1

[0037] Such as figure 1As shown, in the schematic diagram of the process flow of the endless rolling method for profiles, rods and wires, it includes a crystallizer 1, a casting slab 2, a soft reduction roll system 3, a continuous casting slab heating device 7, a large reduction rolling mill 4, a shearing Machine 6, conventional continuous rolling unit 5. A flexible connection device is installed on the conventional continuous casting-rolling production line, and the flexible connection device is selected to be composed of seven pairs of soft reduction roller systems and three large reduction rolling mills. The soft reduction roll system 3 is installed on the cooling section of the continuous casting machine of the conventional continuous casting-continuous rolling production line, and is carried out on the continuous casting slab 2 that has left the crystallizer 1 but has not completed the solidification process, and still has a liquid core and a mushy area. Dynamic soft red...

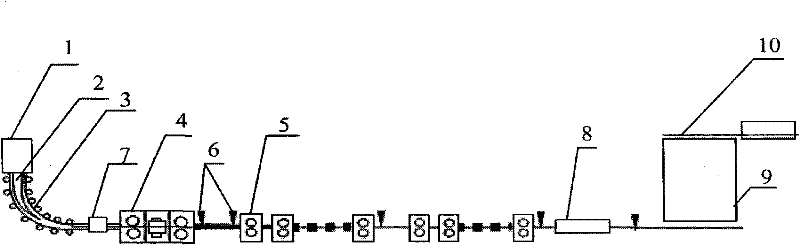

Embodiment 2

[0041] Such as figure 2 As shown in the profile bar and threaded steel bar production line, the cast slab 2 coming out of the crystallizer 1 is rolled by seven pairs of soft reduction rolls 3, the continuous casting slab heating device 7 supplements heat, and the three large reduction rolling mills 4 roll. system, shearing machine 6, the section size and running speed are continuously sent to the conventional continuous rolling mill 5, and the billet is rolled on the conventional continuous rolling production line. The conventional continuous rolling mill 5 includes rough rolling, middle rolling mill, finishing unit. There are also accelerated cooling devices 8, cooling beds 9, and finishing balers 10 in the follow-up to form the entire production line.

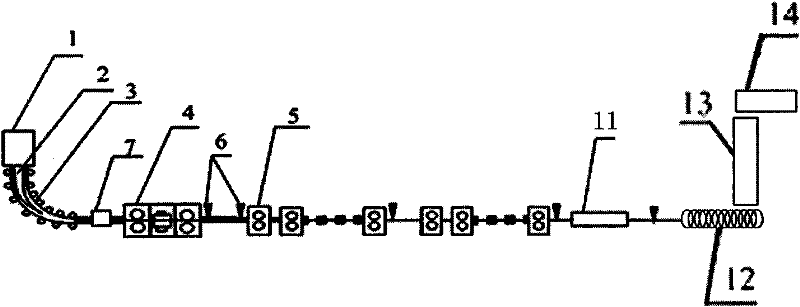

Embodiment 3

[0043] Such as image 3 As shown in the wire rod production line, the cast slab 2 coming out of the crystallizer 1 is rolled by seven pairs of soft reduction rolls 3, the continuous casting slab heating device 7 supplements heat, three large reduction rolling mills 4 rolling, shearing machine 6. The conventional continuous rolling unit 5 is followed by the conventional continuous rolling unit 5. The conventional continuous rolling unit 5 includes a rough rolling unit, an intermediate rolling unit, and a finishing rolling unit, followed by an accelerated cooling device 11, a coil cooling device 12 for the laying machine, a transport chain 13, and a collection unit. Zone 14 constitutes the wire rod production line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com