Toothbrush, toothbrush head and tooth cleaning bristle

A toothbrush head and toothbrush technology, applied in the field of toothbrush bristles, can solve problems such as difficult fixation, difficult fixation of toothbrush bristles, and unfavorable bristle density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

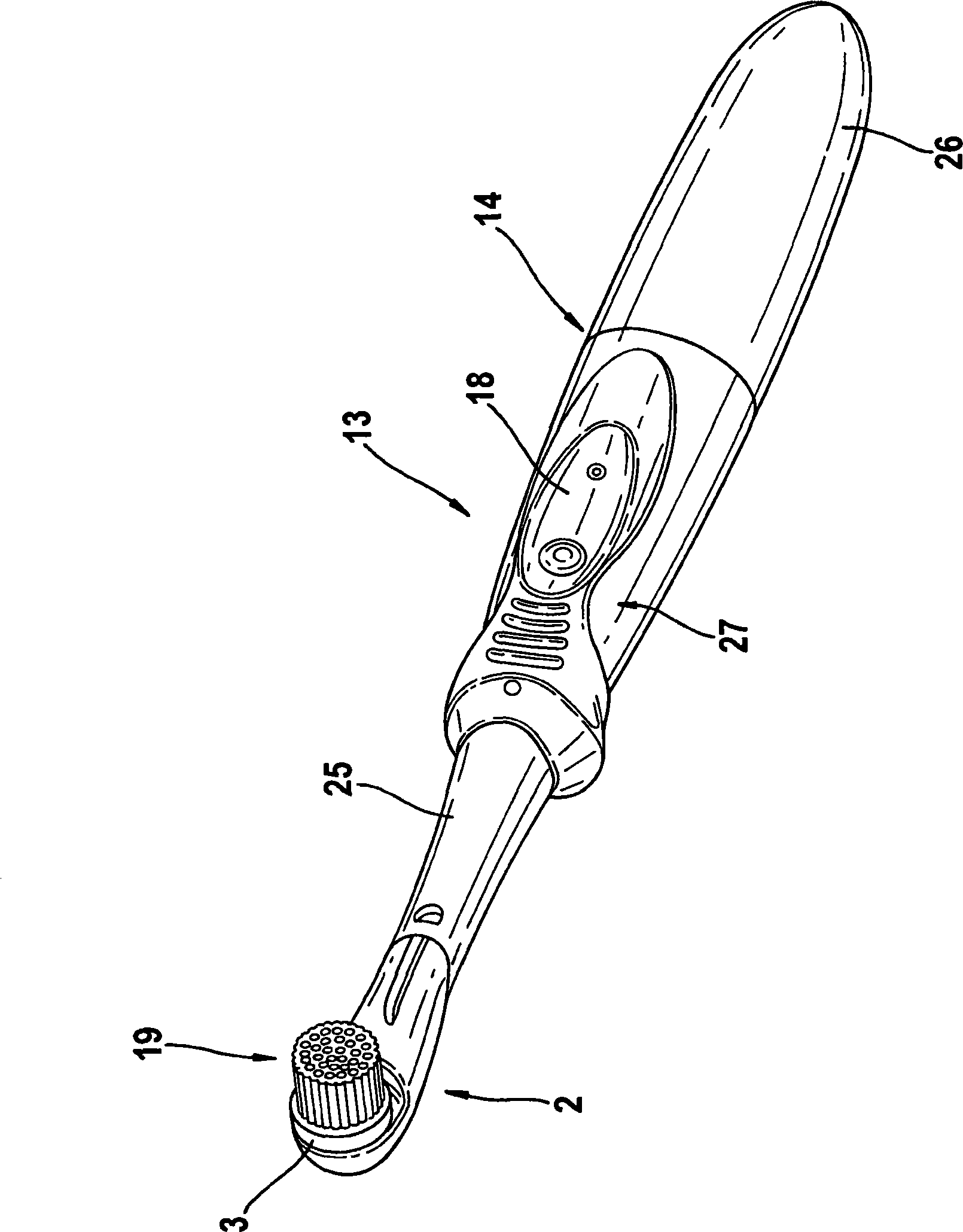

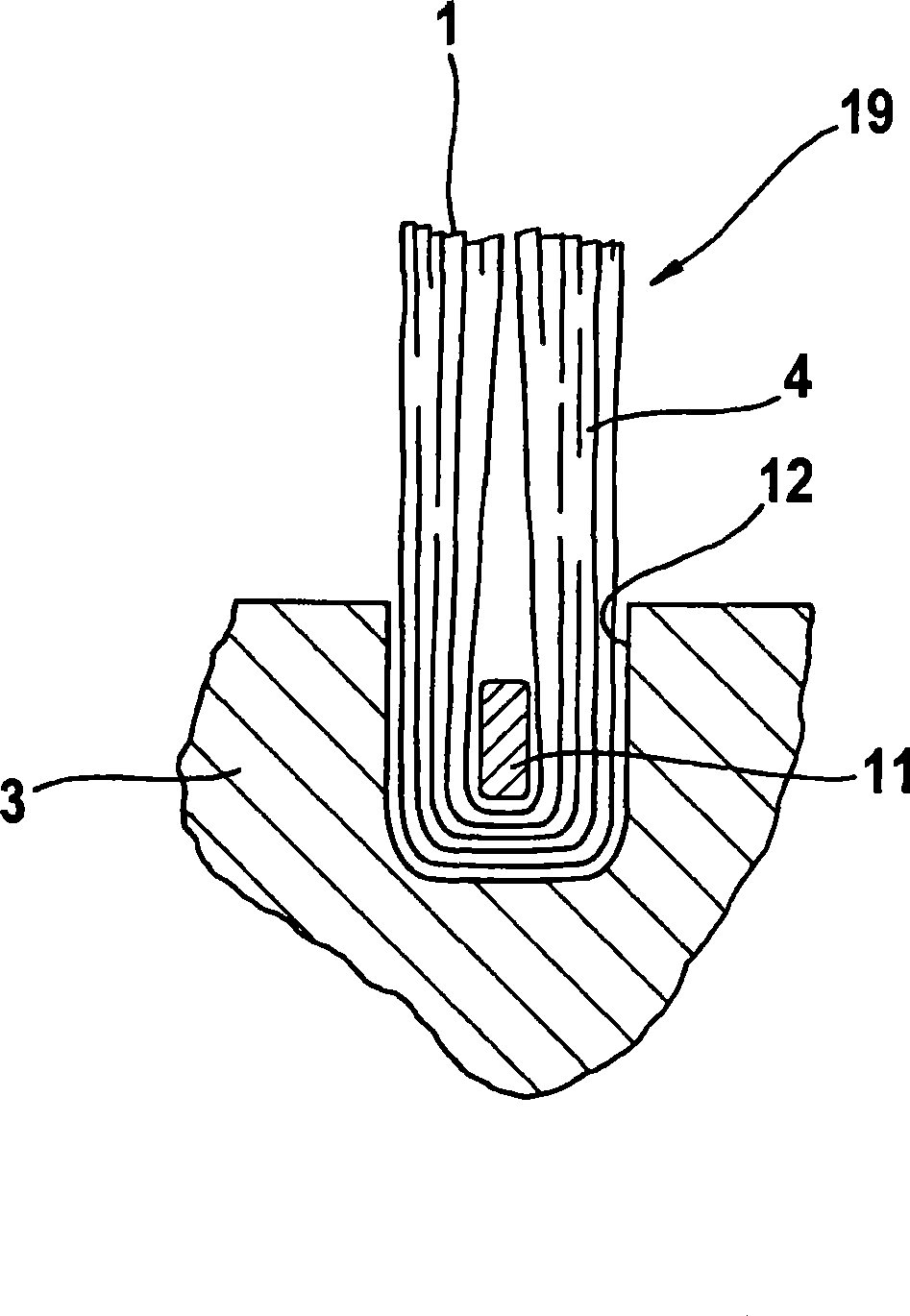

[0030] figure 1 The toothbrush 13 shown comprises a handle part 14 and a toothbrush head 2 mounted on a toothbrush tube 25 which forms the end-side end of the handle part 14 or is connected thereto. The handle part 14 is formed by a toothbrush housing 26 in which a battery compartment and a drive motor 27 are arranged axially one behind the other in a manner known per se. The drive motor 27 can be switched on and off by means of the switch 18 . The disk-shaped bristle carrier 3 of the toothbrush head 2 can be rotationally oscillated by a drive train (not shown separately) comprising a gear mechanism and a converter extending through the toothbrush tube 25 . In the embodiment shown, the substantially cylindrical bristle field 19 is arranged on the bristle carrier 3, as figure 2 What is shown can consist of a large number of bristle bundles 4 .

[0031] figure 2 The bristle bundle 4 shown is advantageously fastened to the bristle carrier 3 by the so-called anchor plugging ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com