Broken-end collection device

A technology for collecting containers and filaments, which is applied in twisting or bending texturing machines, false twist crimping machines, and spinning fields. It can solve problems such as operating process failures and achieve high filling density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

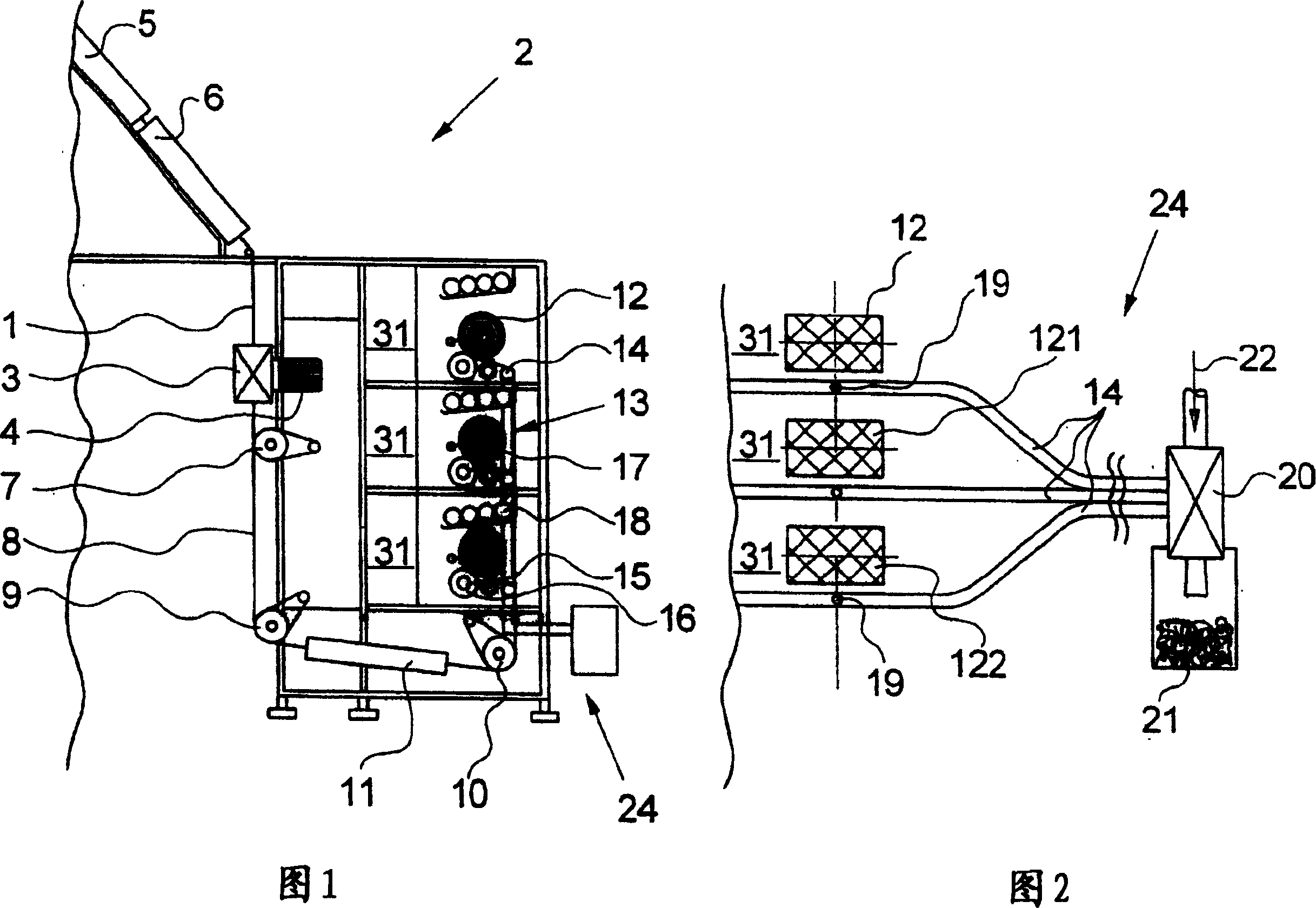

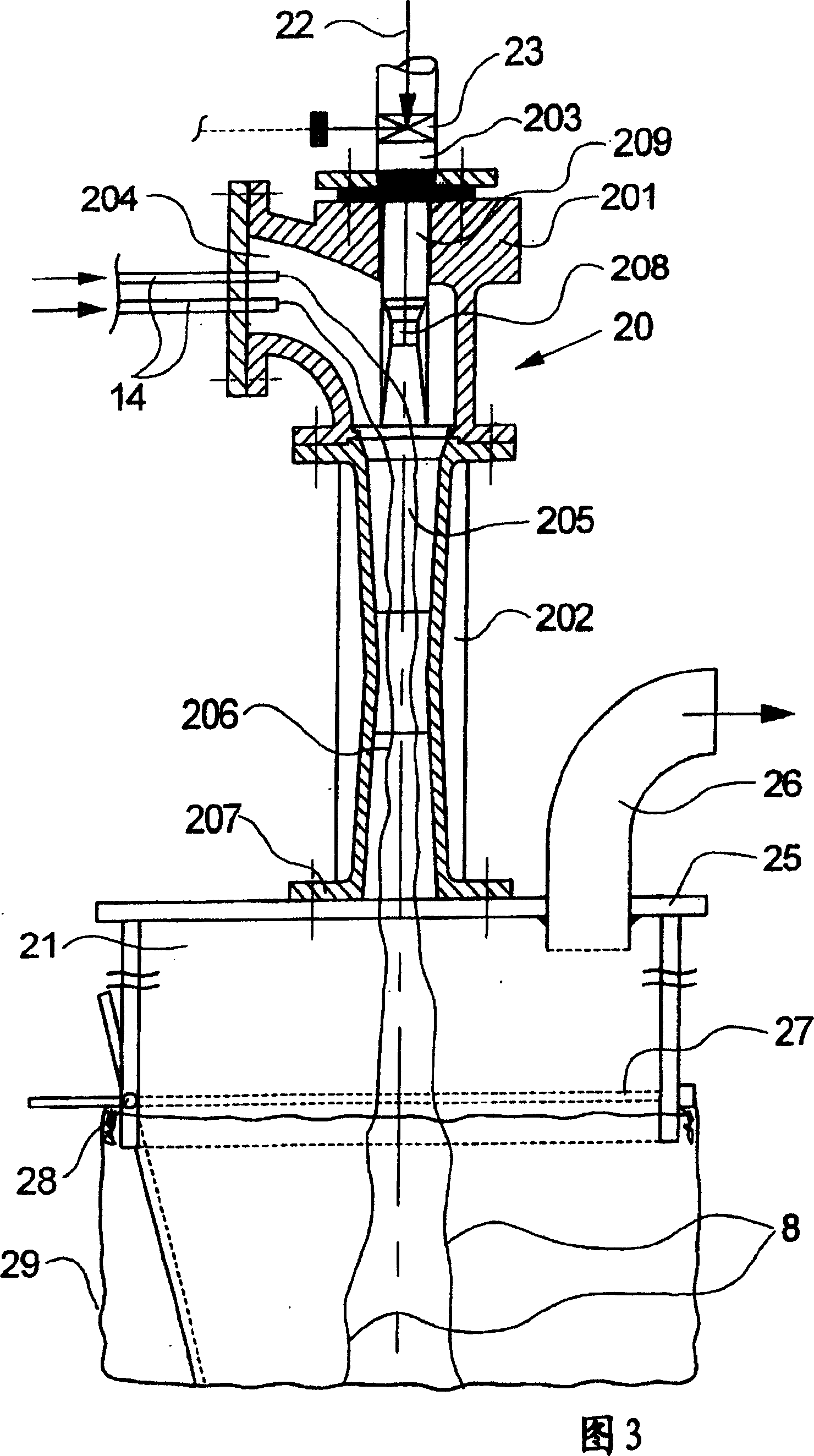

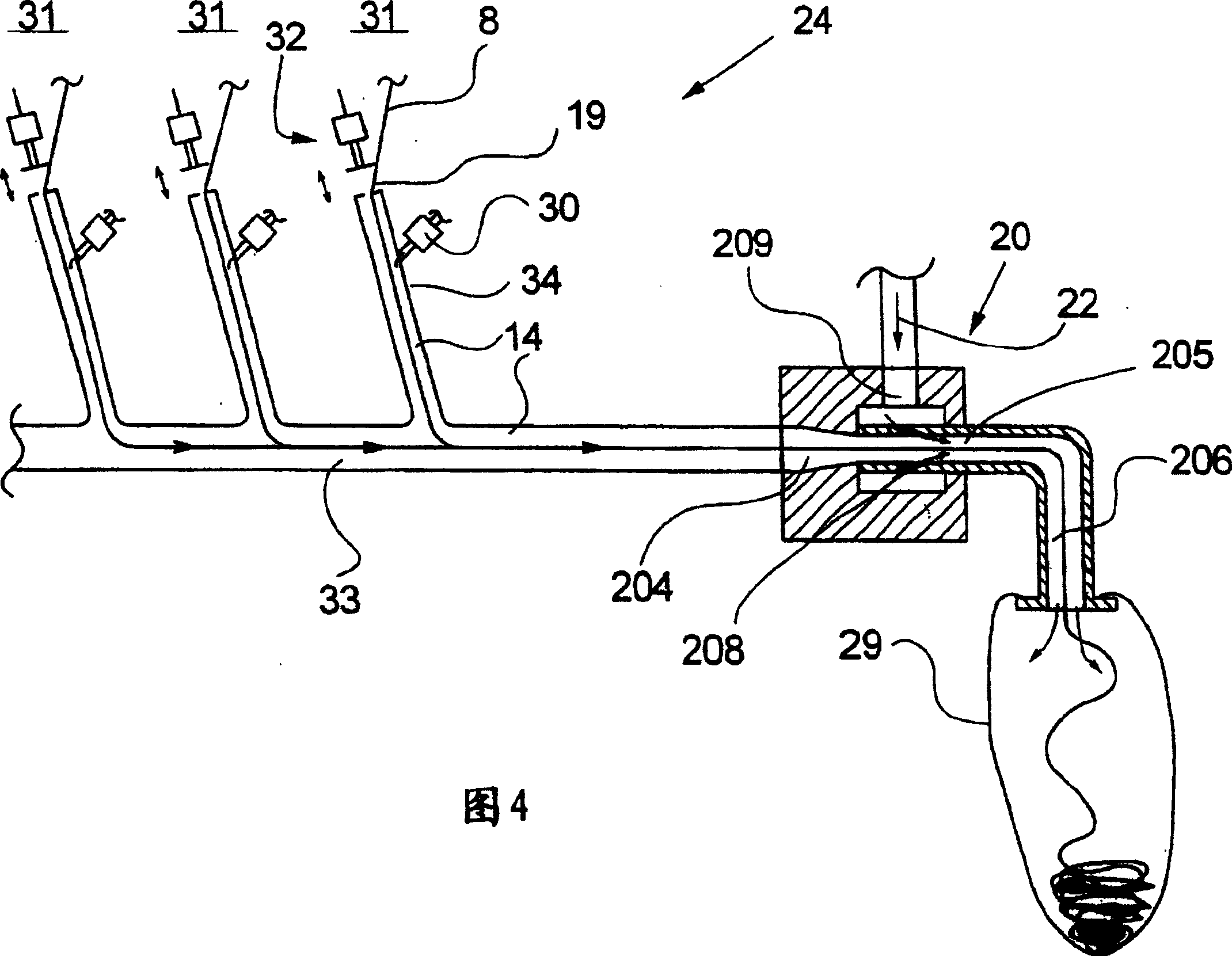

[0021] The present invention is illustrated in FIG. 1 in conjunction with the crimping process. In such a texturing process for continuous synthetic monofilaments of thermoplastic polymers, a filament 1 comprising a plurality of monofilaments is false twisted in a false twist crimper 2 by a texturing device 3 . The latter is provided to consist of a plurality of cooperating friction discs spaced apart from each other and arranged in a row overlapping each other in plan view on parallel driven spindles, the axes of which pass through the corners of an equilateral triangle. In this case the crimping device 3 is directly driven by an electric motor 4, ie one of the three main shafts is directly driven by this electric motor and the other two main shafts are driven via toothed belts. The twist in which the texturing device 3 is applied to the filament 1 is returned from the false twisting device 3 to the fixation heater 5, where the monofilament is softened thermoplastically so th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com