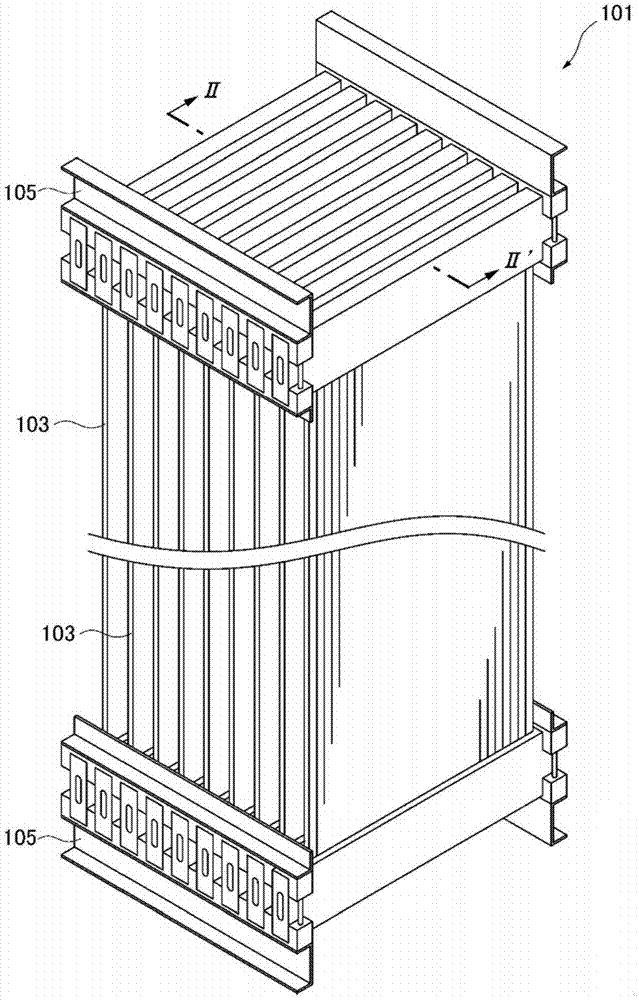

Hollow-fiber membrane module, process for producing hollow-fiber membrane module, and hollow-fiber membrane unit equipped with hollow-fiber membrane module

A manufacturing method and technology of fiber membranes, applied in the direction of chemical instruments and methods, membranes, membrane technology, etc., can solve the problem of decreased permeation rate of treated water, insufficient physical cleaning of hollow fiber membranes, decreased cleaning effect of air diffuser, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

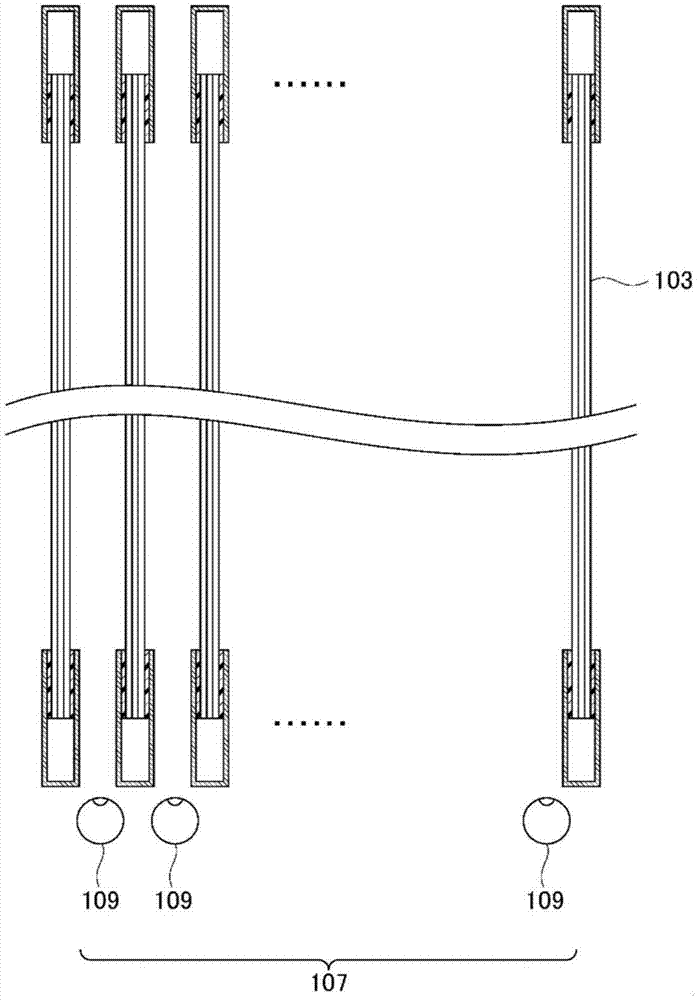

Embodiment 1

[0151] Prepare two hollow fiber membrane sheets, which are hollow fiber membranes made of 160 polyvinylidene fluorides with an effective length of 875 mm (the nominal pore diameter is 0.4 μm, the outer diameter is 2.8 mm, manufactured by Mitsubishi Rayon Corporation) Formed by merging threads in one direction. As the box, an ABS box with a thickness of 7.5 mm was prepared. In a state where two hollow fiber membrane sheets with open upper and lower ends are stacked, the upper and lower ends of the sheets are fixed to the respective boxes with fixing resin (casting resin) made of urethane resin. In the hollow fiber membrane module produced at this time, the ratio of the sum of the cross-sectional areas of the hollow fiber membranes to the area of the horizontal cross section was 53%. Further, the hollow fiber membrane module was fabricated by fixing the hollow fiber membrane module up and down so that the hollow fiber membranes extended in the vertical direction, and arrangin...

Embodiment 2

[0153] Prepare two hollow fiber membrane sheets, which are hollow fiber membranes made of 160 polyvinylidene fluorides with an effective length of 875 mm (the nominal pore diameter is 0.4 μm, the outer diameter is 2.8 mm, manufactured by Mitsubishi Rayon Corporation) Formed by merging threads in one direction. As the box, an ABS box with a thickness of 7.5 mm was prepared. Also, a convex portion with a secondary height of 0.3 mm is formed on the inner wall of the box. In a state where two hollow fiber membrane sheets with open upper and lower ends are stacked, the upper and lower ends of the sheets are fixed to the respective boxes with fixing resin (casting resin) made of urethane resin. In the hollow fiber membrane module produced at this time, the ratio of the sum of the cross-sectional areas of the hollow fiber membranes to the area of the horizontal cross section was 53%. Further, the hollow fiber membrane module was fabricated by fixing the hollow fiber membrane modu...

Embodiment 3

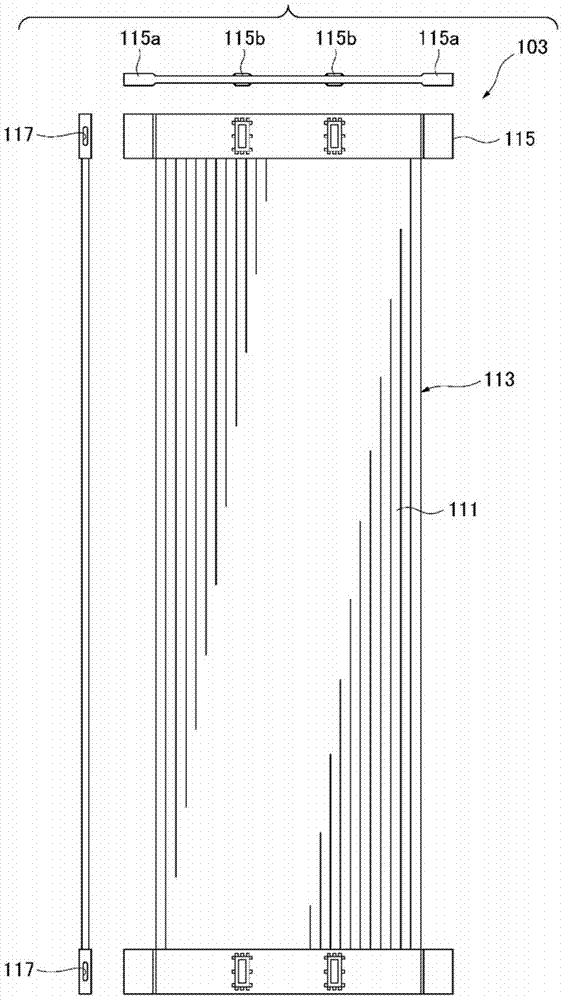

[0185] Two tanks having a divided structure with external dimensions of L340mm×W6mm×H50mm were prepared, and these were superimposed and welded to produce an ABS water collecting member of L340mm×W12mm×H50mm. An opening of L300 mmmm x W6 mm x 20 mm and a water collecting flow path of L300 mm x W6 mm x H20 mm corresponding to the opening are formed on the water collecting member. In addition, water inlets having an inner diameter of 6 mm in diameter are formed at both ends of the water collecting member. In addition, columnar bodies having a circular cross-section with an outer diameter of 6 mm in diameter are equally formed on the water collecting flow path, left, right, up and down. The water collecting part and the connection structure are welded together by solvent adhesive (Ethelon No.73). As the fixing resin of the hollow fiber membrane, polyurethane resin (4423 / 4426, Nippon Polyurethane) was used to fix the laminated body of the hollow fiber membrane sheet to the water ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Nominal aperture | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com