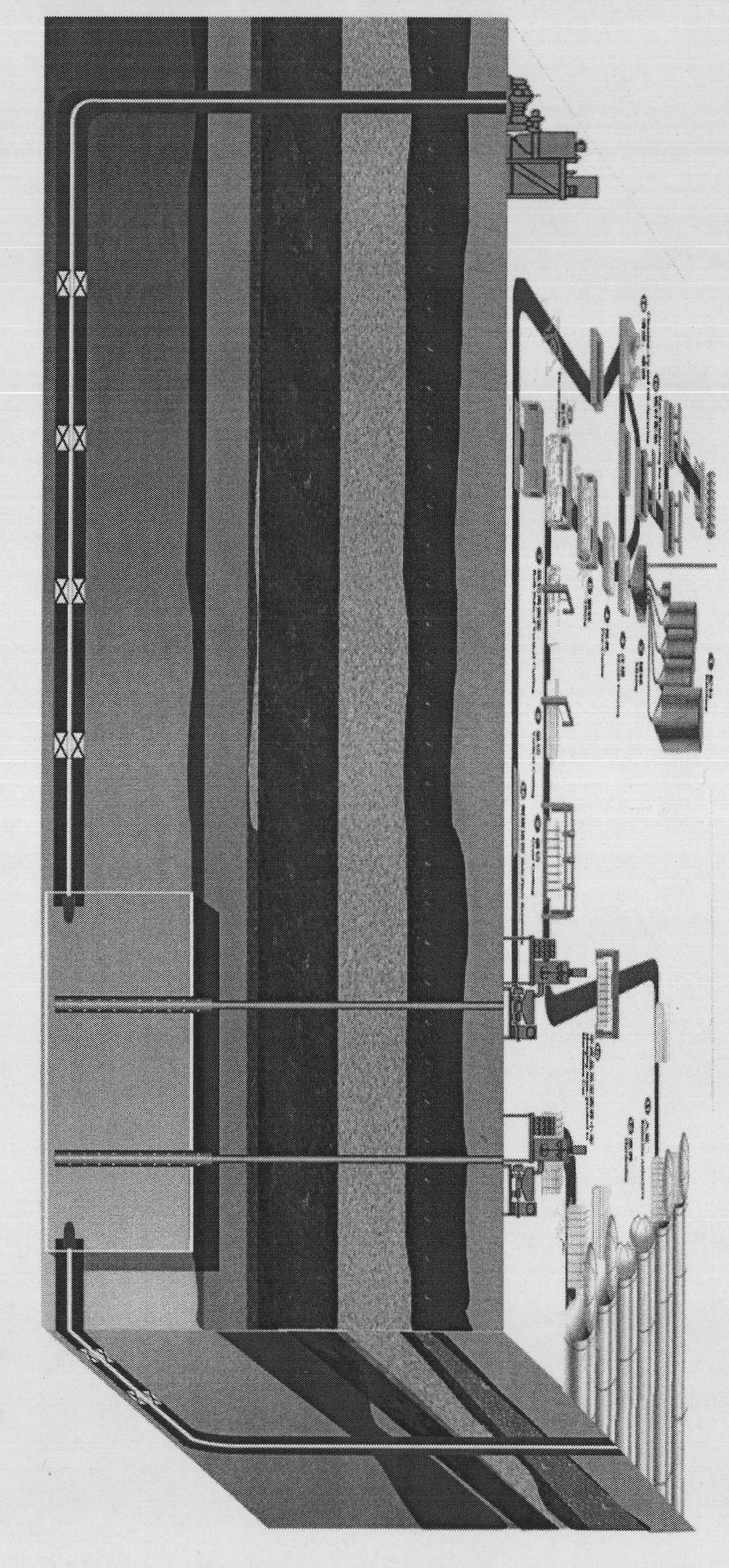

Ultra-deep coal underground gasification technology

An underground gasification and ultra-deep technology, applied in coal gasification, underground mining, mining fluids, etc., can solve problems such as inability to mine, low mining efficiency, and long mining time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0005] The present invention is further described below: ultra-deep coal underground gasification technology: at first, carry out precise detection according to coal burial depth and delineated shape, design a main axis in the coal seam of deep gasification according to geological conditions and structure to be infinitely long and Continuously extend and infinitely extend the gasifier and gas storage channel cavity; among them: design a gas production vertical shaft and a horizontal well every 300 meters long, and burn a deep channel; after the combustion gas storage channel combustion furnace is established, every A 1,500-meter-long horizontal well is drilled at 50 meters, and every 300 meters is a horizontal section, which is infinitely enlarged according to the coal seam. Installed in the horizontal well: high temperature resistant movable retractable igniter, steam injection water pipe, special pipeline device for oxygen enrichment injection; then use butane and electric ig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com